Down pipe device for high-intensity flash iron-making furnace and control process thereof

An iron-making furnace and high-strength technology, applied in the field of metallurgy, can solve problems such as low equipment operation rate, insufficient utilization of coal gas chemical energy and physical heat, and difficult pre-reduction control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

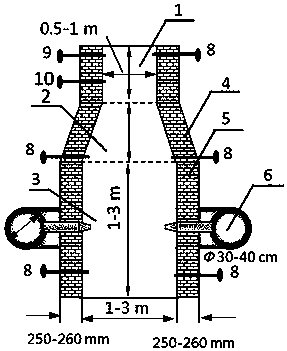

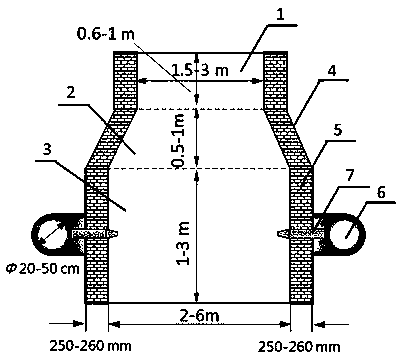

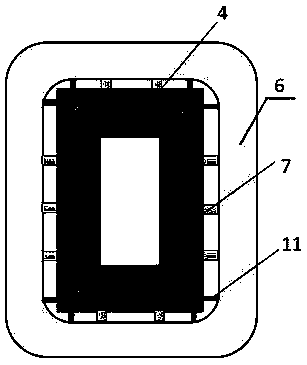

[0032] Embodiment 1: see Figure 1 to Figure 3 , a downcomer device for a high-strength flash ironmaking furnace, comprising an upper rectangular downcomer 1, a middle wedge-shaped downcomer 2 and a lower rectangular downcomer 3 that are sealed and communicated sequentially from top to bottom.

[0033] The cross-section and longitudinal section of the upper rectangular feeding pipe 1 are rectangular, that is, the upper rectangular feeding pipe 1 is a cuboid, the cross-section of the wedge-shaped feeding pipe 2 in the middle is rectangular, and the longitudinal section of the wedge-shaped feeding pipe 2 in the middle is rectangular. Both are trapezoidal, and the cross section and longitudinal section of the lower rectangular feeding pipe 3 are rectangular, that is, the lower rectangular feeding pipe 3 is a cuboid;

[0034] The width of the upper rectangular blanking tube 1 is consistent with the bottom width of the middle wedge-shaped blanking tube 2, and the width of the botto...

Embodiment 2

[0048] Embodiment 2: A downcomer control process of a high-strength flash ironmaking furnace, using the downcomer device of the high-strength flash ironmaking furnace in Embodiment 1. The downcomer is between the rotary kiln and the melting furnace. By adjusting the process parameters of the downcomer, the precise control of the furnace top gas temperature, pressure, flow rate and charge temperature can be realized.

[0049] Specifically, the length of the upper rectangular feeding pipe 1 is 1.5-3 m, the width is 0.5-1 m, and the height is 0.5-3 m.

[0050] 1 m; the temperature of the upper rectangular feeding pipe 1 is controlled at 900-1100°C, and the gas composition is controlled at a CO volume percentage of 40-60%, which can be specifically 40%, 45%, 50%, 55% or 60% , CO 2 The volume percentage of H is 20-30%, specifically it can be 20%, 22%, 25%, 28% or 30%, H 2 The volume percentage is 7 to 15%, specifically it can be 7%, 9%, 10%, 12% or 15%, N 2 The volume fraction i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Lower width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com