Fiber grating pressure sensor, manufacture method and method for monitoring load of asphalt pavement

A pressure sensor and fiber grating technology, which is applied in the field of civil engineering sensor testing, can solve problems such as large interference, and achieve the effects of high sensitivity, good real-time performance and good damage resistance.

Inactive Publication Date: 2011-06-15

NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

View PDF3 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to solve the problem of large interference in asphalt pavement monitoring and the accuracy of the current monitoring method, and propose a high-sensitivity, low-interference fiber grating pressure sensor and its manufacturing method and asphalt pavement load monitoring method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

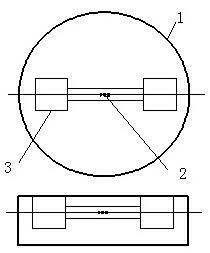

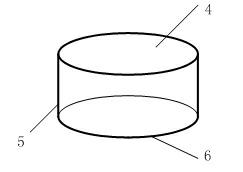

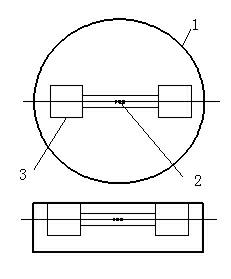

The invention relates to a fiber grating pressure sensor, a manufacture method and a method for monitoring the load of an asphalt pavement, belonging to the test field of a civil engineering sensor. The structure comprises a metal outer shell (1), a Bragg fiber grating (2) and a polymer part (3), wherein the Bragg fiber grating (2) is mounted in metal outer shell (1), the polymer part (3) is used for encapsulating the Bragg fiber grating (2) in the metal outer shell (1) and comprises a left cube, a right cube and a spindly horizontal cube, the left cube and the right cube are fixed at the lower side of an upper metal cover (4), the spindly horizontal cube is fixed between the left cube and the right cube, the structure is integrally in a dumbbell shape; the Bragg fiber grating (2) is encapsulated in the spindly horizontal cube of the polymer part (3) along the horizontal direction, and transmission fibers at both ends extend out of the left cube and the right cube. By utilizing the dumbbell-shaped structure in the invention, the sensibilization of the fiber grating pressure sensor is realized, and the sensitivity of the sensor is increased.

Description

Optical fiber grating pressure sensor and manufacturing method and asphalt pavement load monitoring method Technical field The invention relates to a fiber grating pressure sensor, a manufacturing method and an asphalt pavement load monitoring method, and belongs to the field of civil engineering sensor testing. Background technique Highways are closely related to human life and play a decisive role in the economic development of a country and region. They are the link for communication between various regions. They also undertake the tasks of passenger and freight transportation. They are fast and convenient. In order to adapt the highway to the development pattern of the national economy and coordinate with other modes of transportation, establish an efficient, fast and safe key highway system and national trunk line system, so that the highway capacity can meet the overall social development and national economy. my country has specially formulated a national key highway pla...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01L1/24

Inventor 曾捷梁大开王晓洁孙晓明穆昊刘宏月

Owner NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com