Device for testing mechanical properties of thin sheet under simple shear loading

A simple and mechanical technique, applied in the direction of using a stable shear force to test the material strength, using a stable tension/pressure test to test the material strength, measuring devices, etc. Accurately measure shear stress and strain and other issues to improve accuracy, ensure stability and reliability, and achieve serial effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is described in further detail below in conjunction with accompanying drawing:

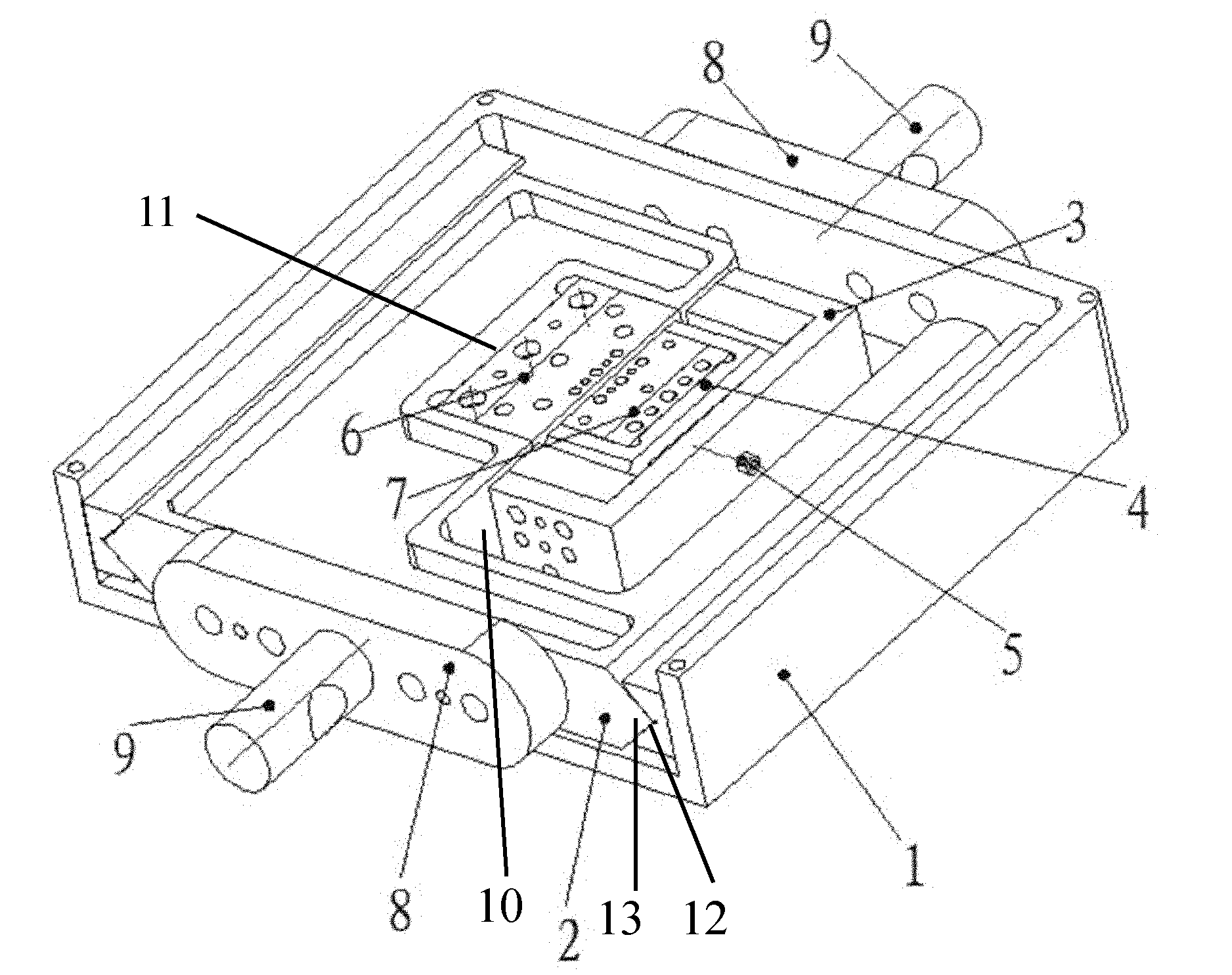

[0024] see figure 1 The device for testing the mechanical properties of thin plates under simple shear loading of the present invention comprises a box-shaped base 1 with a rectangular opening. The left clamp assembly 6 and the right clamp assembly 7 , wherein the gap between the left clamp assembly 6 and the right clamp assembly 7 is along the axial direction of the base 1 .

[0025] The right clamp assembly 7 is fixed on the slider 4 and can move together with the slider 4, and the slider 4 is embedded on the fixed block 3 with a concave structure, and the slider 4 is entirely located in the fixed block 3 as shown in the figure. In the recess, the fixed block 3 is fixed on the base 1 . The notch of the fixed block 3 is equivalent to a guide rail, and the slide block 4 can slide on the notch of the fixed block 3 to drive the right clamp assembly 7 close to or away f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com