Method and device for verifying high-accuracy direct-current comparator

A direct current, high-accuracy technology, applied in the field of electrical measurement, can solve problems such as high cost, cumbersome verification process and data processing, and inability to directly verify 1:1 ratio errors, so as to overcome errors, achieve uniform and symmetrical electrical performance, and avoid Effect of Lead Resistance Interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

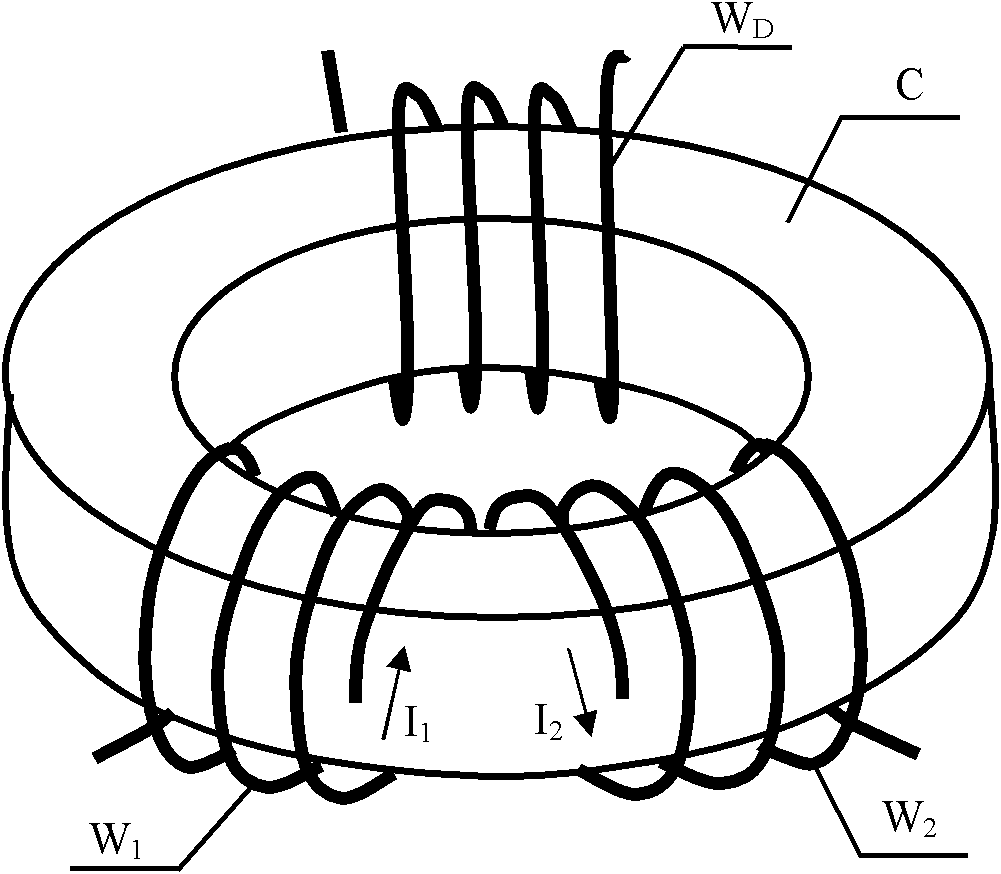

[0054] The present invention will be described below in conjunction with the accompanying drawings.

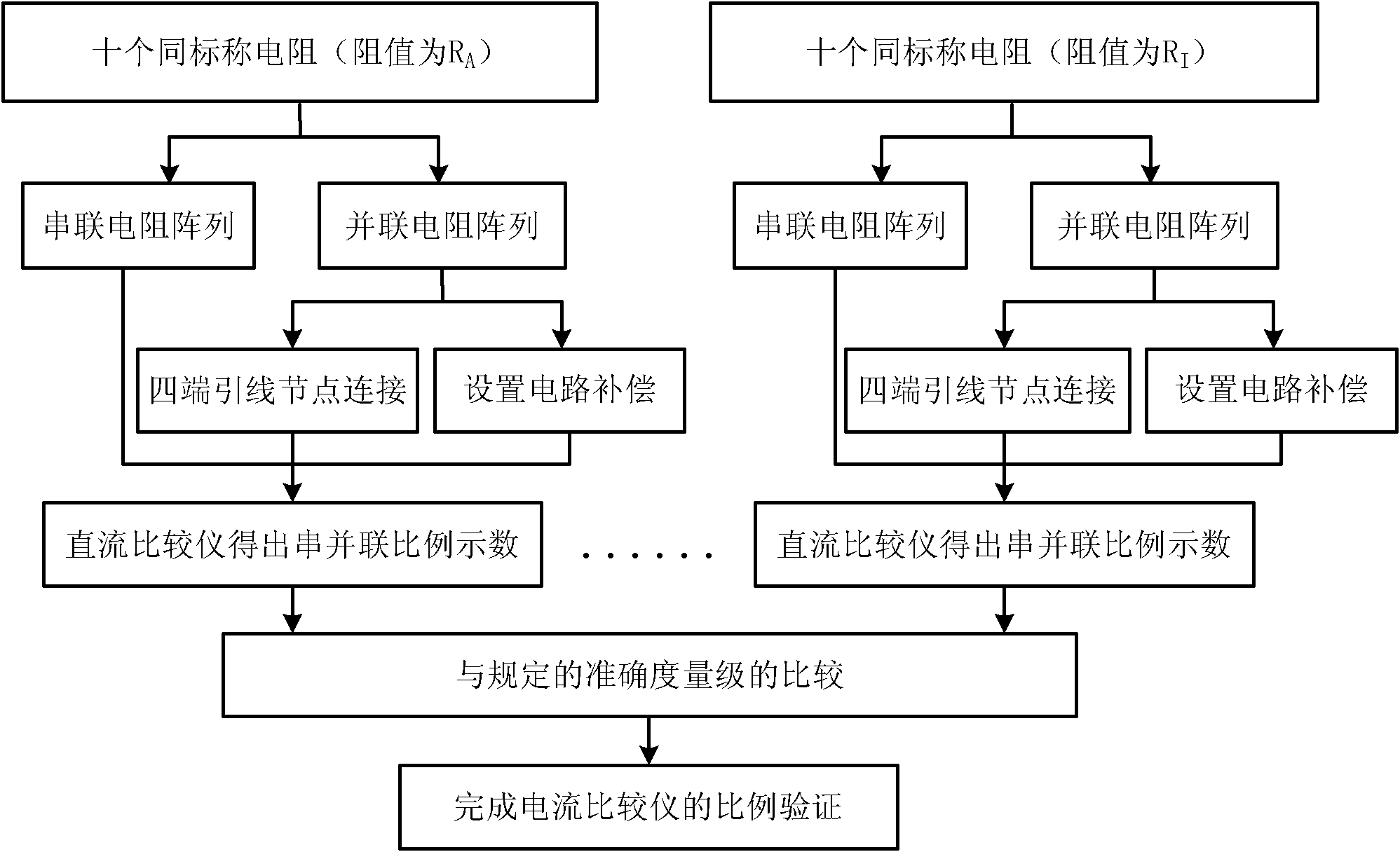

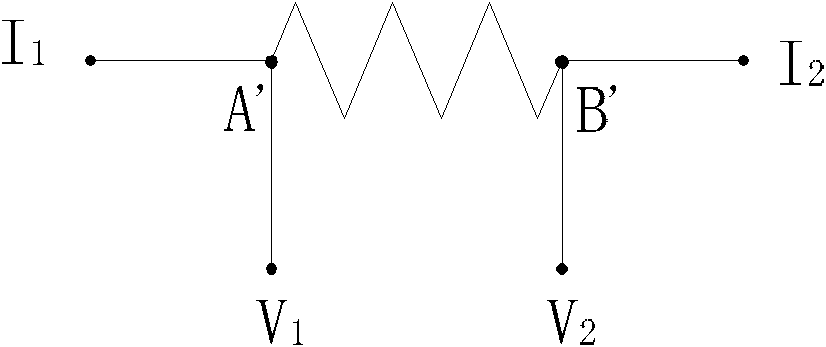

[0055] figure 2 It is a flow chart of the verification method of the high-accuracy DC current comparator for resistance measurement of the present invention. First connect ten resistors with the same nominal value (resistance value is R A ) are connected in series and parallel to form a series resistance array and a parallel resistance array respectively. The parallel resistance array uses a four-terminal lead node structure to connect the nodes at both ends of each parallel resistance, and when the resistance arrays are connected in parallel, the external short circuit is used to set the short circuit compensation, and then through the DC The current comparator is used for proportional measurement, and the DC current comparator can obtain the series-parallel proportional display respectively; three or more groups of resistors are connected in series and parallel, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com