Direction line winding mechanism for telescope

A telescope and coil-line technology, applied in telescopes, optics, instruments, etc., can solve the problems of undiscovered, hard water pipes, and difficult to control the azimuth axis of the telescope, and achieve the effect of improving adaptability and meeting the requirements of rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

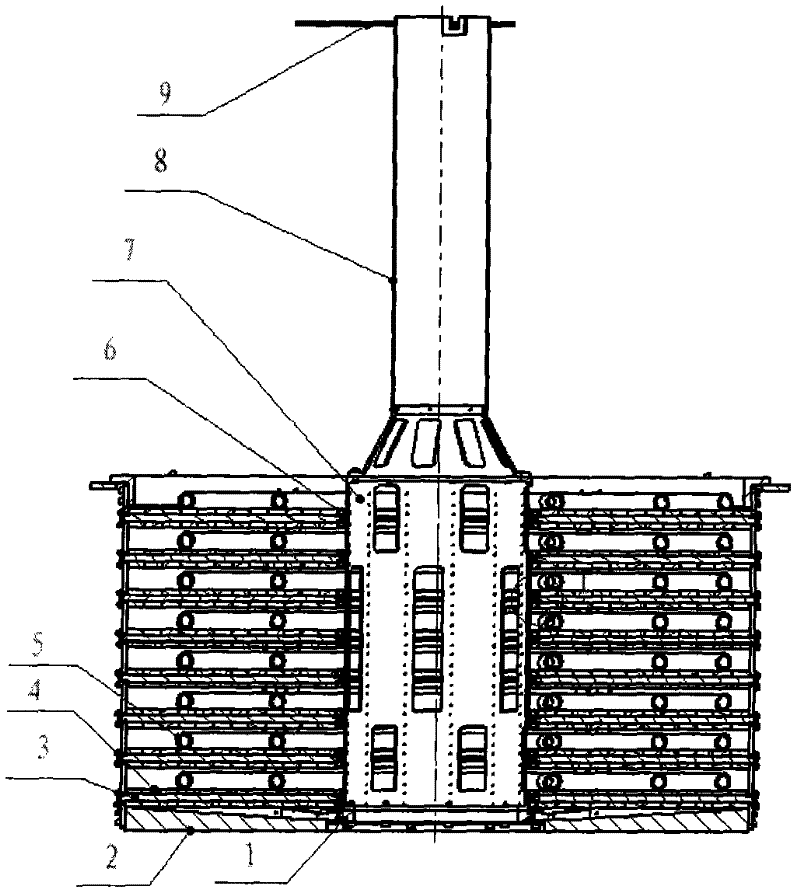

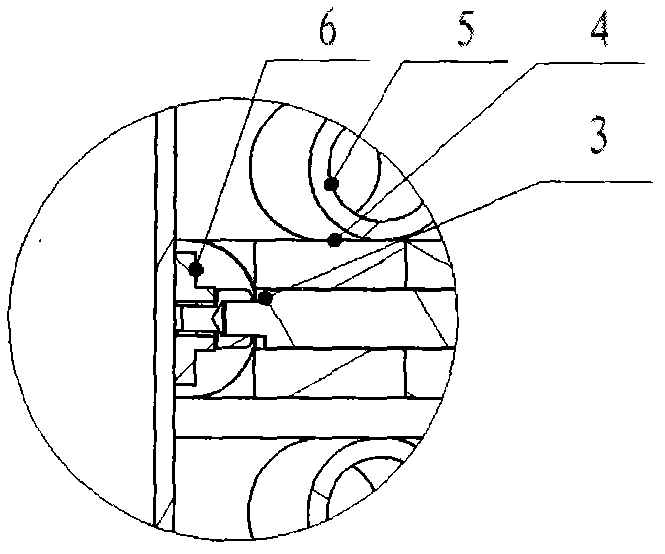

[0017] The invention can make the water pipes and air pipes on and off the connecting machine work normally without affecting the azimuth rotation axis. number to realize the pipeline connection machine up and down without affecting the rotation of the telescope azimuth axis, that is, when the rotating cylinder 7 rotates, the water pipe and the air pipe adapt to the rotation angle of the telescope azimuth axis by changing the number of coils.

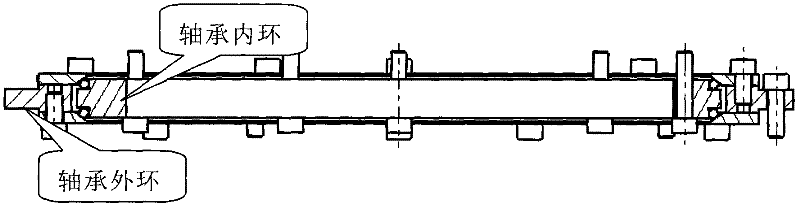

[0018] Such as figure 1 , 2 , 3, the azimuth coil mechanism is a structure that can be independently assembled and operated. It has a rotatable bearing 1. The bearing outer ring of the bearing 1 is connected to the fixed base frame group 2. 7 connection, driven by the connecting pipe 8 and the Oldham slip ring 9, the inner ring of the bearing can rotate synchronously with the azimuth axis of the telescope, and the fixed pedestal group 2 is fixed on the base of the equipment to ensure that the inner and outer rings of the bearing 1 have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com