Badminton testing machine

A badminton and testing machine technology, applied in the field of testing equipment and badminton testing machines, can solve problems such as unfavorable reduction of cost production efficiency, low competitiveness of badminton, long manual training cycle, etc., to improve testing quality, simple structure, and meet rotation requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

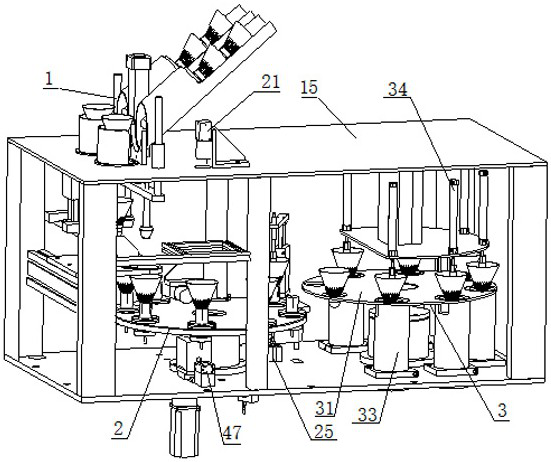

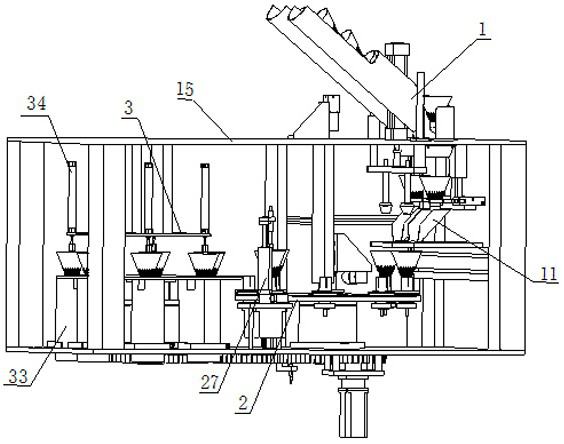

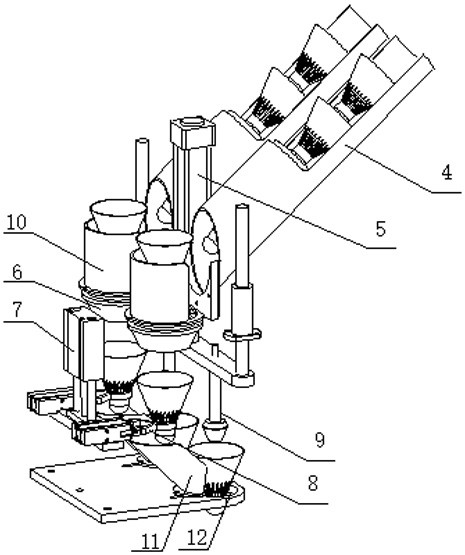

[0025] Attached below Figure 1-Figure 5 The badminton testing machine of the present invention is further described in detail:

[0026] The badminton inspection machine of the present invention includes a frame body 15, a controller, a ball-up mechanism 1, a detection mechanism 2 and a ball-down mechanism 3. The upper ball mechanism 1, the detection mechanism 2 and the lower ball mechanism 3 are respectively connected to the frame body 15 and connected with the controller signal. Under the coordinated control of the controller, the upper ball mechanism 1 automatically sends the badminton to be detected to the detection mechanism 2 After completing the detection of the shuttlecock, it is sent to the lowering mechanism 3, and finally the automatic sorting of the shuttlecocks with different detection results is completed under the control of the controller.

[0027] In this example, in order to improve the detection efficiency, the ball loading mechanism 1 includes two feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com