Rotating driving force receiver and drive component

A technology for driving components and receiving heads, which is applied in the fields of electrography, optics, instruments, etc., can solve problems such as jamming, and achieve the effect of avoiding jamming, simple assembly and stable operation.

Active Publication Date: 2011-06-15

PRINT RITE UNICORN IMAGE PROD CO LTD

View PDF7 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

When the process cartridge is dropped or taken out, the problem of jamming easily occurs between the rotary drive force receiving head in the above-mentioned photosensitive drum drive assembly and the drive part of the imaging device

Therefore, the above-mentioned photosensitive drum driving assembly still has room for further improvement

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

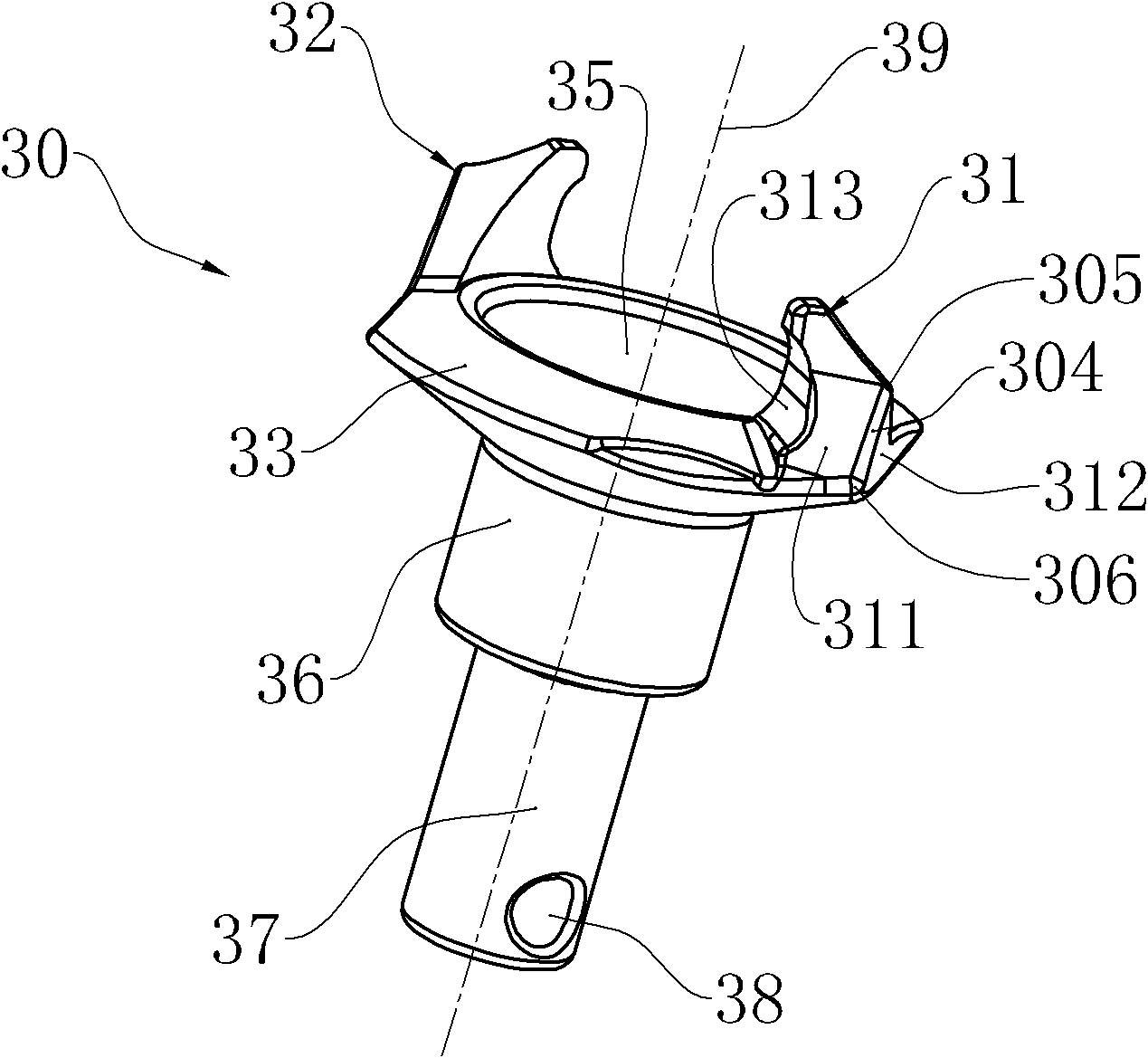

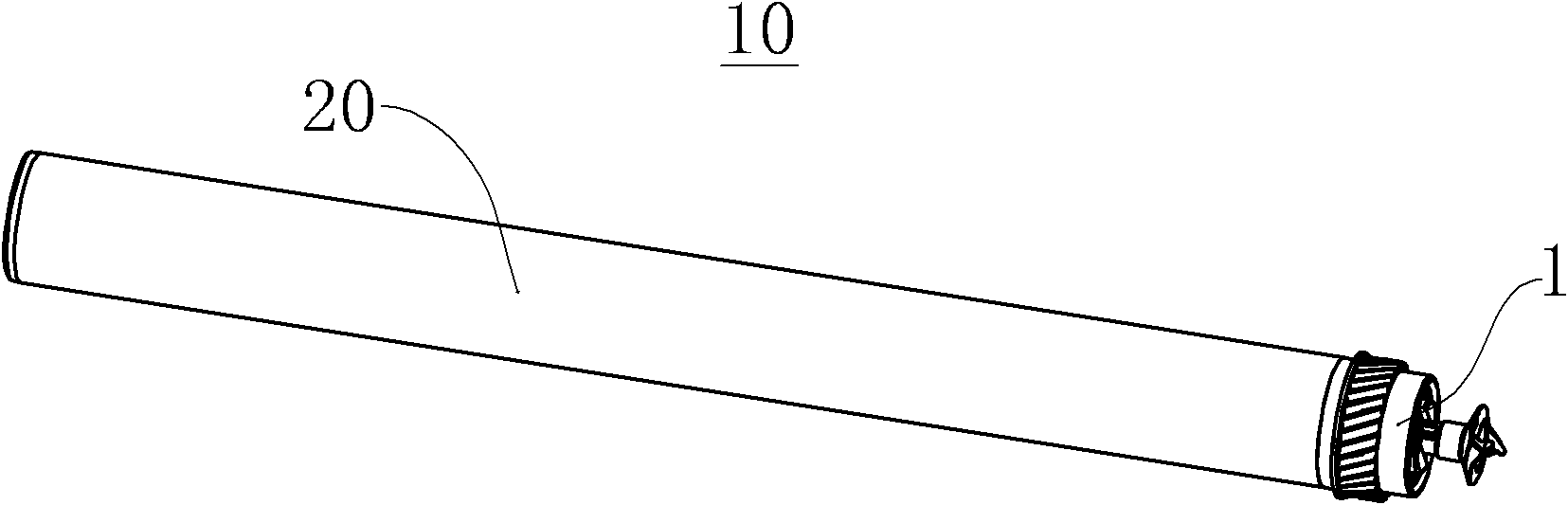

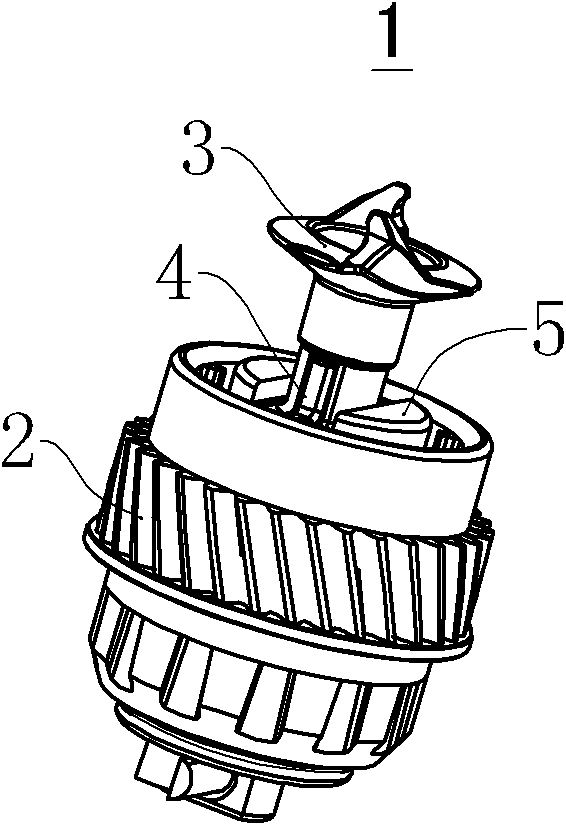

The invention relates to a rotating driving force receiver and a drive component. The receiver is provided with an inwards concave spherical surface, an approaching surface positioned on the periphery of the spherical surface, and a first convex pawl and a second convex pawl extended outwards, wherein the surfaces of each of the convex pawls are both provided with an occlusal surface matched with an imaging equipment drive component and two side surfaces which are used for guiding and are transited smoothly; the two side surfaces are abutted through a transition edge which is inclined relative to the direction of an axial line; the transition edge is provided with a first endpoint and a second endpoint; the second endpoint is positioned on the second surface; a first bottom line and a second bottom line are crossed at the second endpoint; the second endpoint is a point, farthest from the axial line, on a convex pawl; and the first endpoint is closer to the axial line than the second endpoint. The rotating driving force receiver and the drive component can reduce a dead point position area when a machine falls or a processing cartridge is taken out to the maximum and avoid a locking problem between the rotating driving force receiver and the imaging equipment drive component, so that a photosensitive drum can be driven to work safely and reliably.

Description

Rotary drive receiver and drive assembly technical field The present invention relates to a rotary driving force receiving head and a drive assembly having the rotary driving force receiving head. Background technique Electrophotographic image forming apparatuses include copiers, laser printers, and the like. An electrophotographic image forming apparatus generally has a process cartridge in it, and the process cartridge can be attached to and detached from the main assembly of the electrophotographic image forming apparatus. For example, a process cartridge prepared by integrally assembling a photosensitive drum, and at least one of developing means, charging means and cleaning means as process means into a cartridge body. Existing process cartridges include the following types: a first process cartridge prepared by integrally assembling a photosensitive drum and a developing device, a charging device, and a cleaning device in a cartridge; and a second process cartridg...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G03G15/00G03G21/18

CPCG03G15/757G03G21/186

Inventor 汤付根周宏辉

Owner PRINT RITE UNICORN IMAGE PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com