A kind of centrifugal force automatic brake mine car

A technology of centrifugal force and brake, which is applied in the direction of railway braking system, brake components interacting with the track, railway car body parts, etc. and other issues, to achieve the effect of easy mechanization and standardized manufacturing, easy sealing, dustproof, waterproof and maintenance, and simple shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

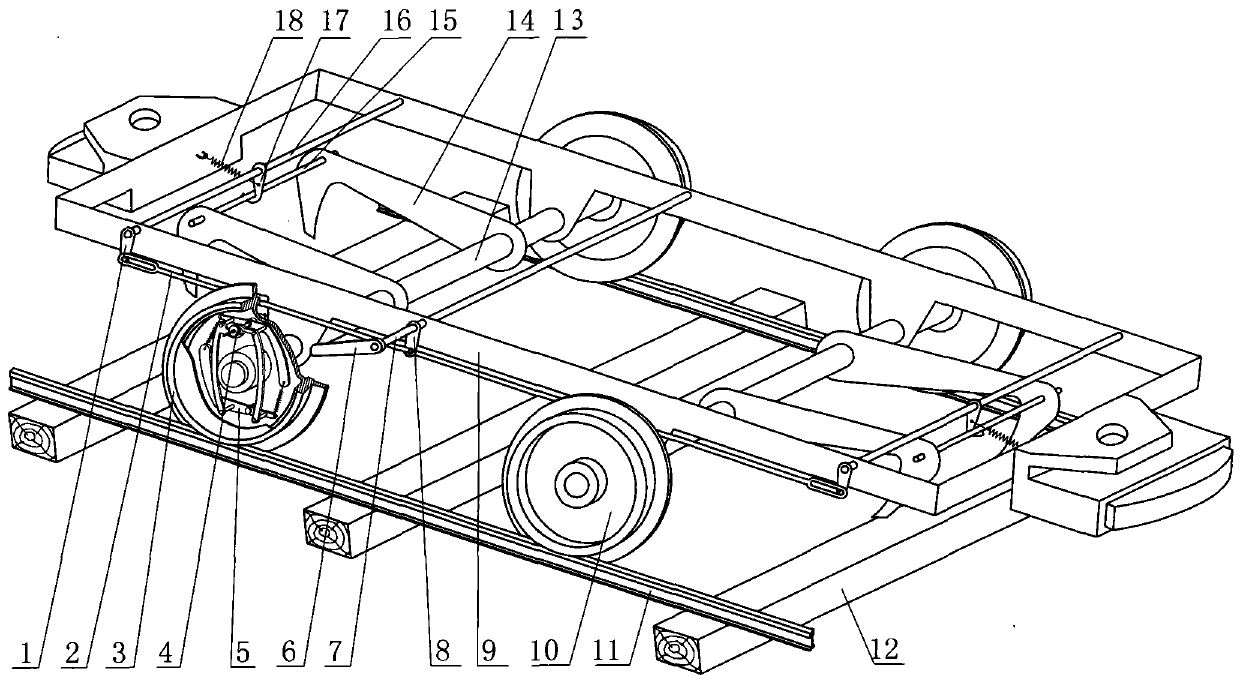

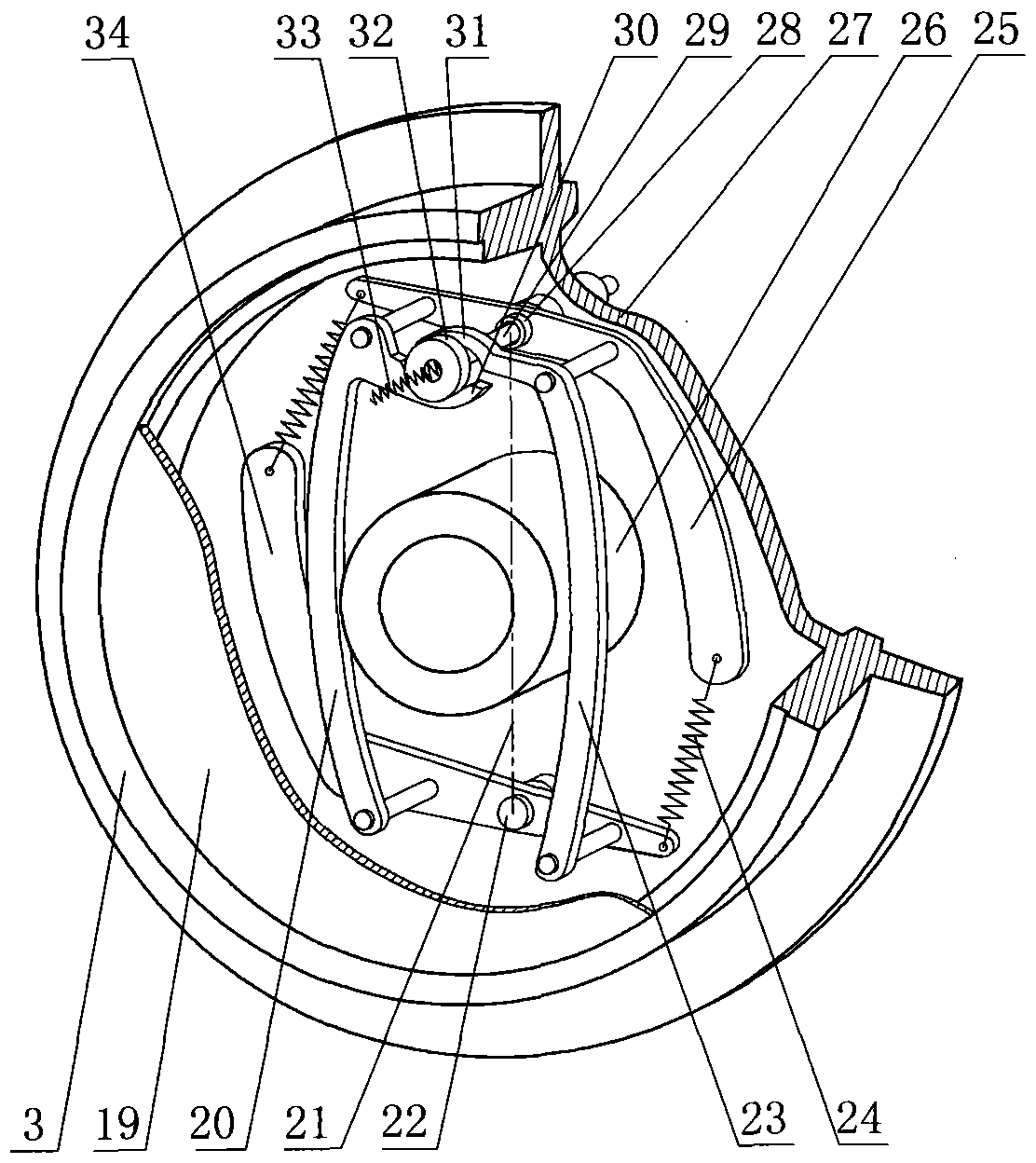

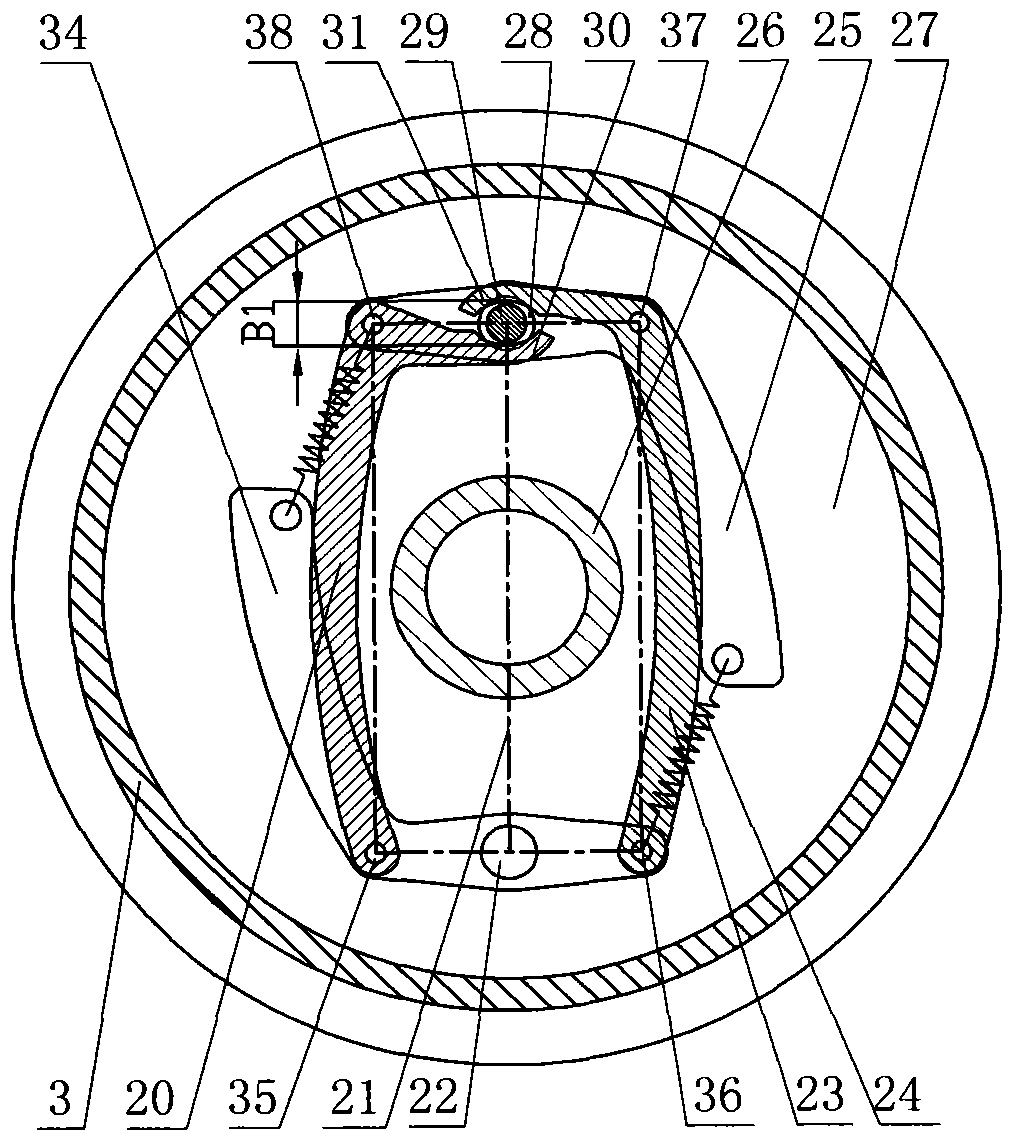

[0054] figure 1 Shown is the basic structure schematic diagram of the embodiment of the brake of the present invention is a claw type brake claw, figure 2 shown as figure 1 Enlarged view of the centrifugal wheel in . combine figure 1 with figure 2 The details are as follows:

[0055] Basic structure mainly comprises vehicle frame 9, centrifugal wheel 3, centrifugal mechanism 5, driving rod ejection device 4, brake mechanism and braking brake 14. Centrifugal mechanism 5 and driving lever ejection device 4 are arranged in the centrifugal wheel 3, and with wheel rotation, drop brake mechanism and braking brake 14 are arranged on vehicle frame 9.

[0056] Centrifugal mechanism comprises centrifugal plate 25, centrifugal plate 34, centrifugal plate hinge shaft 22, centrifugal plate spring 24, inner clamp balance connecting plate 20 and outer clamp balancing connecting plate 23, and another centrifugal plate hinge shaft is controlled by driving rod sliding sleeve 28 replace....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com