A monitoring system for power supply equipment

A technology for power supply equipment and circuit detection, which is applied in the direction of measuring electricity, measuring electrical variables, and detecting faults according to conductor types, etc., can solve the problems of low maintenance work efficiency and on-site troubleshooting, etc. The effect of ensuring the reliability of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

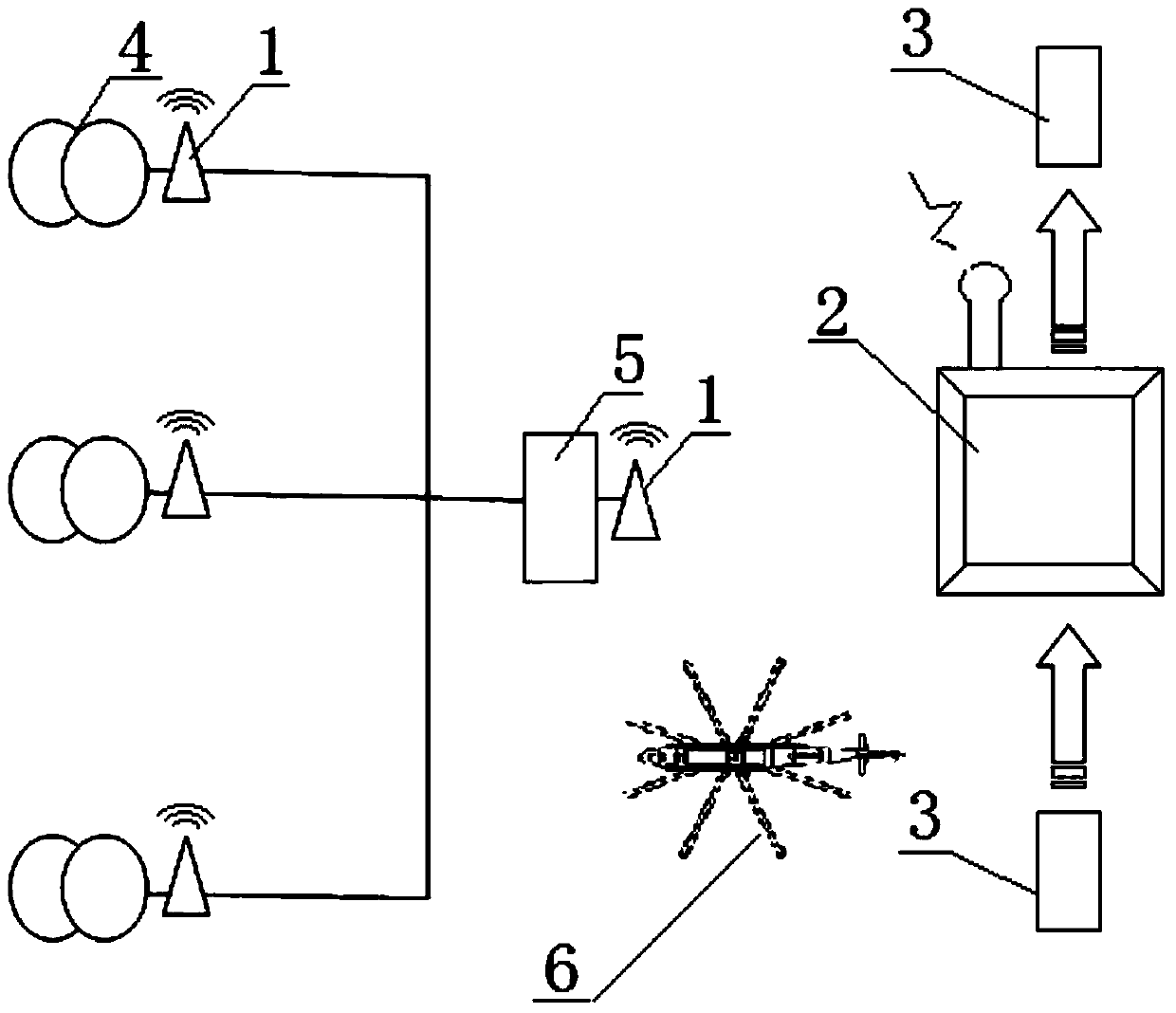

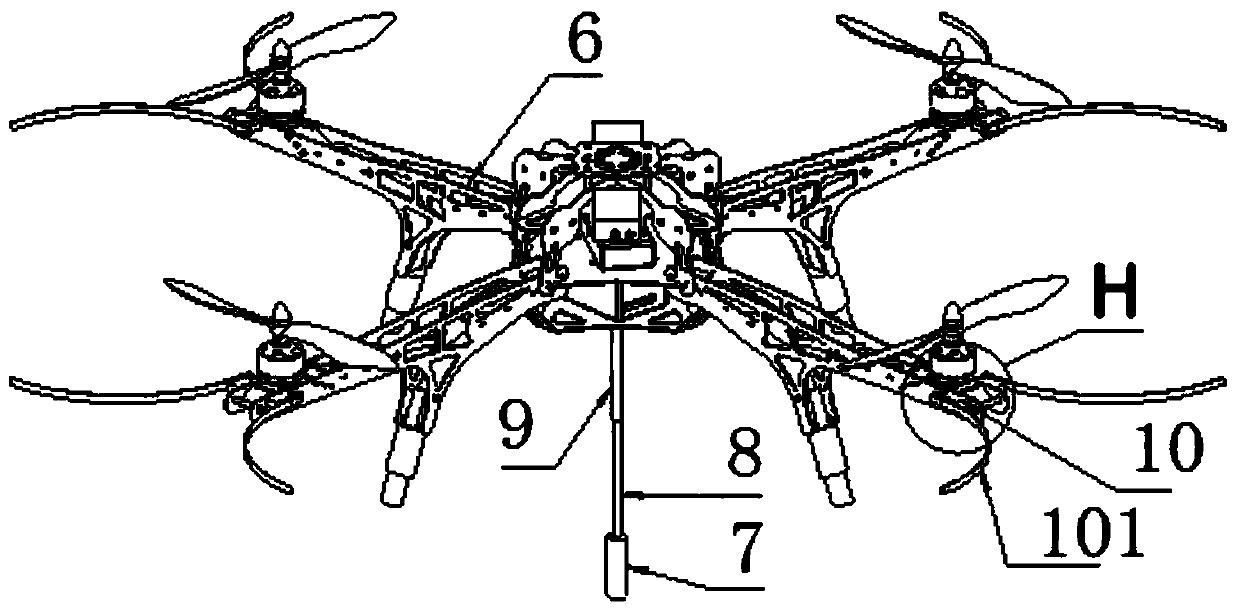

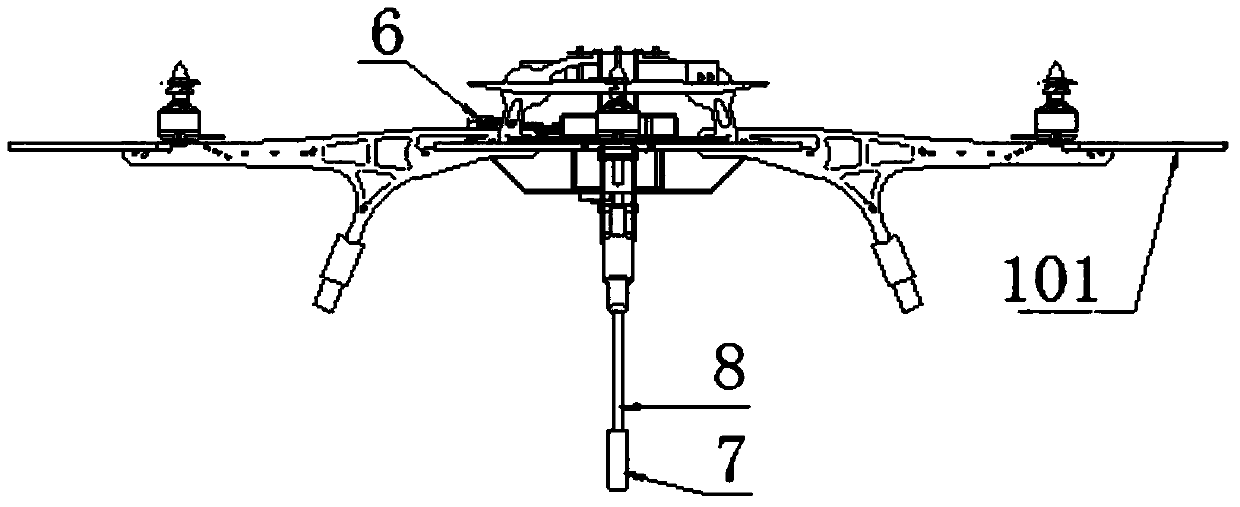

[0022] Figure 1 to Figure 5 is an embodiment of the present invention, such as figure 1 As shown, a power supply equipment monitoring system includes a circuit detection terminal 1, a monitoring switchboard 2, a patrol drone 6, and a mobile phone 3. The circuit detection terminal 1 is installed on the terminals of each transformer 4 and line segment switch 5, and patrols The unmanned aerial vehicle 6 is distributed on the power supply line, the inspection drone 6 is provided with a camera, and the monitoring software is installed in the mobile phone 3. The figure shows that fault data and fault points are sent to the supervisory switchboard 2, and the circuit detection terminal 1 and the inspection drone 6 are connected to the surveillance switchboard 2 through a wireless data module....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com