Process for preparing membranes

A group and composition technology, applied in the field of film making, can solve the problems of slow curing and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

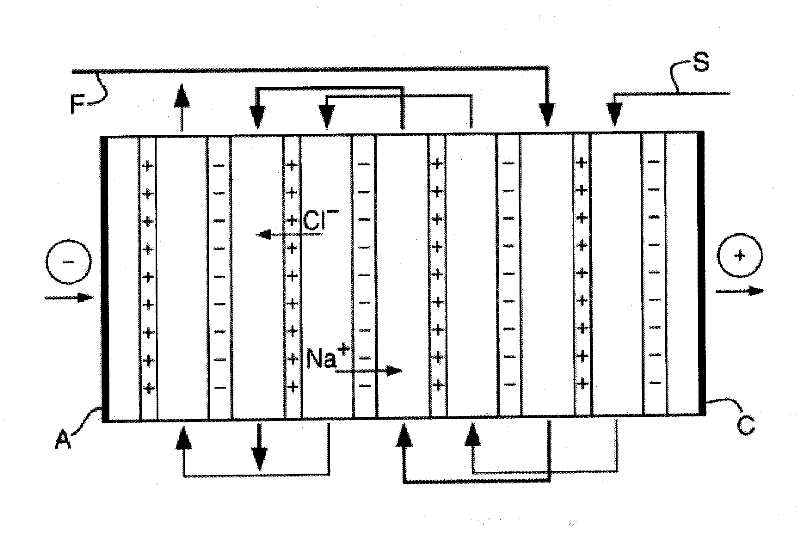

Method used

Image

Examples

example 1

[0159] A curable composition ("CC1") was prepared by mixing the ingredients shown in Table 1:

[0160] Table 1

[0161] Element

Content (wt%)

[0162] Ebecryl TM 3703

74.2

DMAPAM

24.8

Irgacure TM 500

1.0

[0163] Step (i) - Applying curable compound to the support

[0164] The curable compound CC1 was applied to a thickness of 150 microns on a support (paper extrusion coated with polyethylene layer).

[0165] In this example, reinforcement material (woven SEFAR) was coated on layer CC1 and flattened using a 150 micron rod / blade coater.

[0166] Step (ii) - Curing

[0167] Films were prepared by curing the product of step (i) at a speed of 15 m / min (single pass) using a LightHammer LH6 from Fusion UV Systems equipped with a D lamp operating at 100% intensity. The curing time was 0.8 seconds.

[0168] The resulting membrane was removed from the support and kept in 0.5M NaCl solution (buffered to pH ...

example 9

[0183] The film produced in Example 9 disintegrated upon drying. The decomposition on drying of the membrane produced in Example 9 and the low permselectivity of the membrane produced in Example 10 indicated that the compositions containing methacrylate could not cure as fast as the other examples without methacrylate.

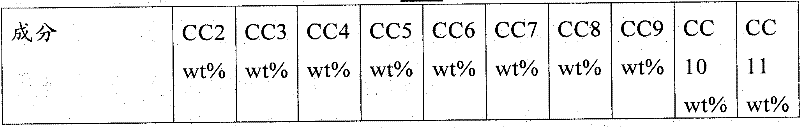

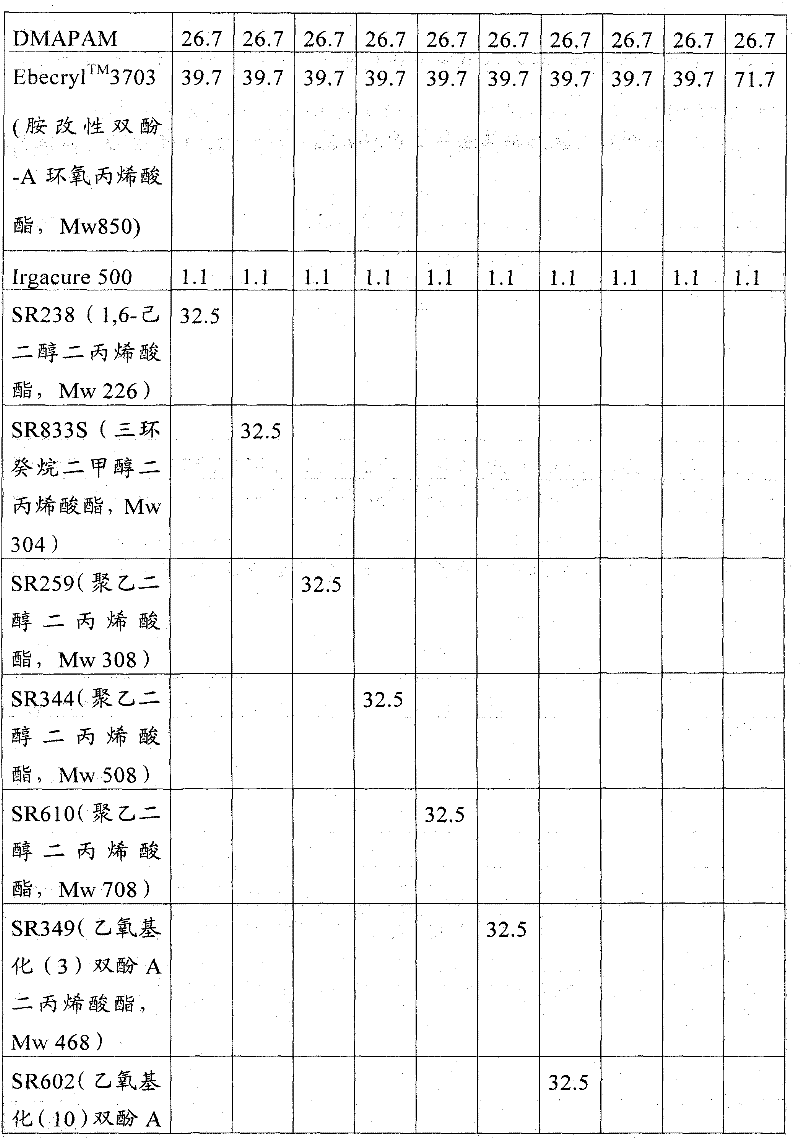

[0184] Examples 12 to 14

[0185] Other curable compositions CC12 to CC14 were prepared according to the formulations shown in Table 4:

[0186] Table 4

[0187] Element

CC12wt%

CC13wt%

CC14wt%

DMAPAM

33.1

33.1

49.4

Ebecryl TM 3703

49.2

49.2

49.2

Irgacure TM 500

1.4

1.4

1.4

SR238

16.3

SR349

16.3

[0188] Films were prepared from curable compositions CC12 to CC14 using the method described in Example 1 above, except Novatexx 2473 was used in place of the woven Sefar and excess curable composition was removed using a 4 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com