Vehicle frame tube and manufacturing method thereof

A manufacturing method and frame tube technology, applied in the field of the manufacturing method and the frame tube manufactured by the manufacturing method, can solve the problems of consuming a lot of materials, cost of multiple materials of the spherical head tube, heavy weight, etc., and achieve material saving Effects of cost, reduction of structural strength and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

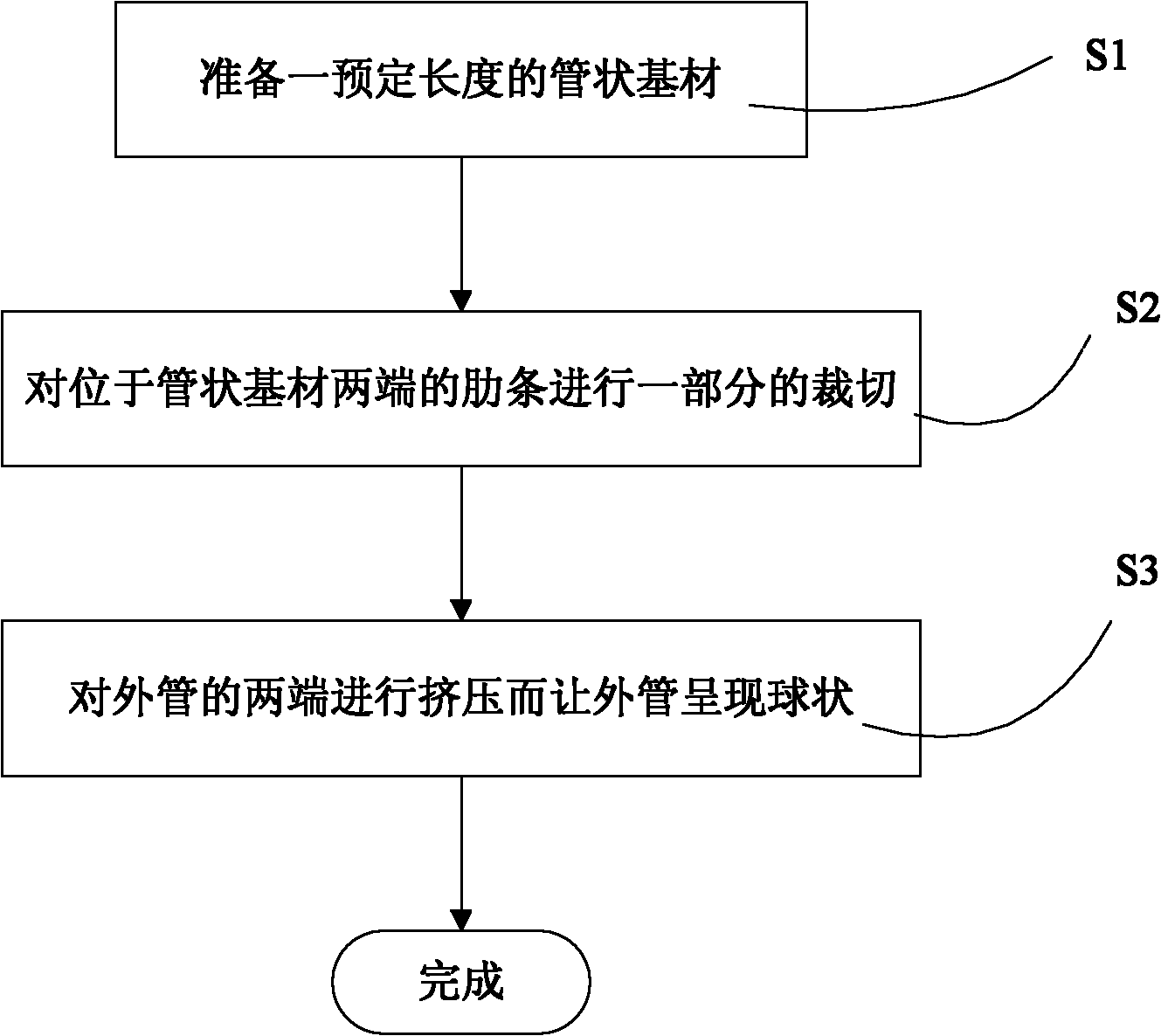

Method used

Image

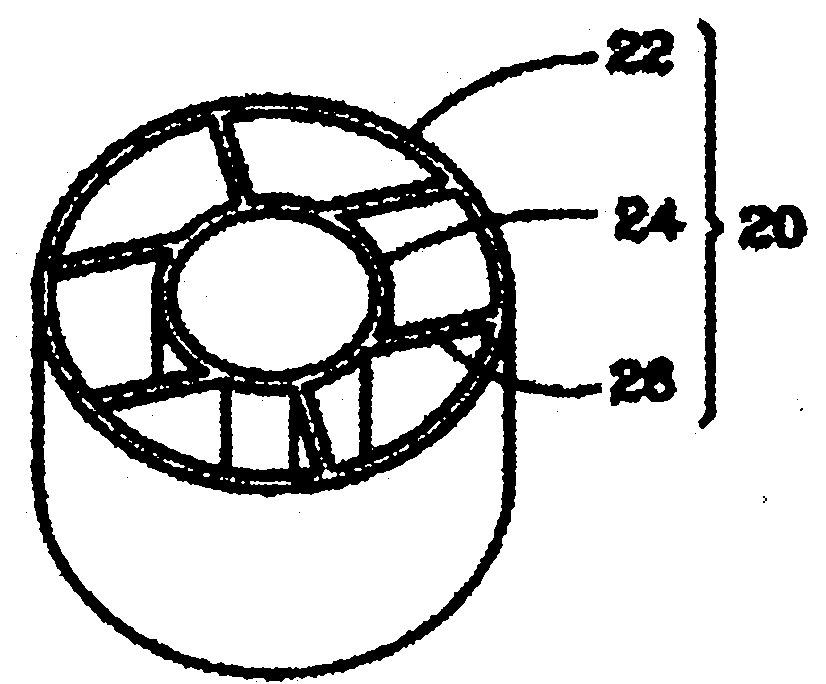

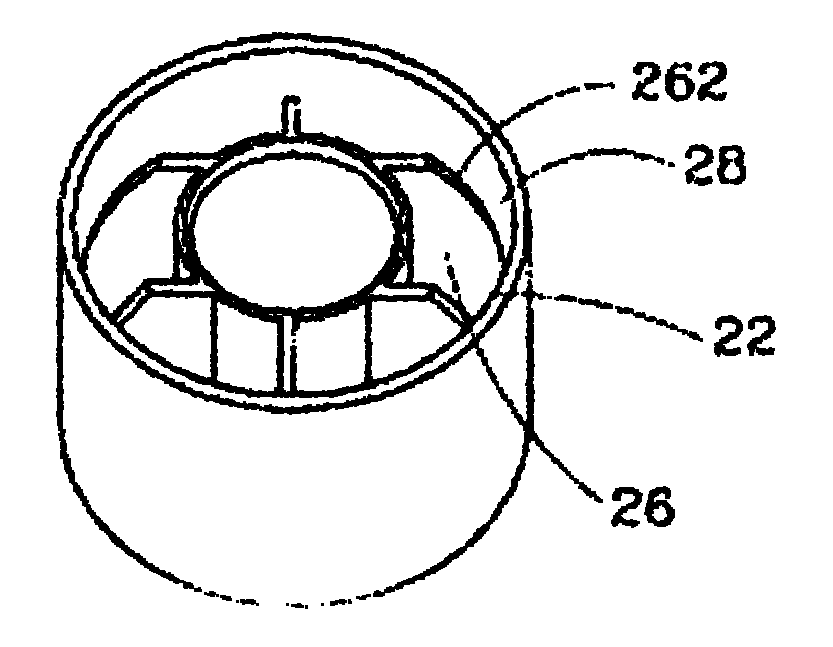

Examples

Embodiment 1

[0040] See Figure 5 , the schematic diagram of the application of the frame tube of the present invention to a bicycle, the frame tube can be used in the front wheel connection 40 between the front and rear forks and the wheel, the rear wheel connection 50, and the connection between the frame and the seat tube, in addition Besides, other similar positions all can use this vehicle frame pipe structure.

Embodiment 2

[0042] See Figure 6 , is a schematic diagram of the application of the frame tube 10 of the present invention to a scooter. In addition, other similar parts can use this frame tube structure.

[0043] The frame tube 10 of the present invention can also be applied to baby walkers and skateboards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com