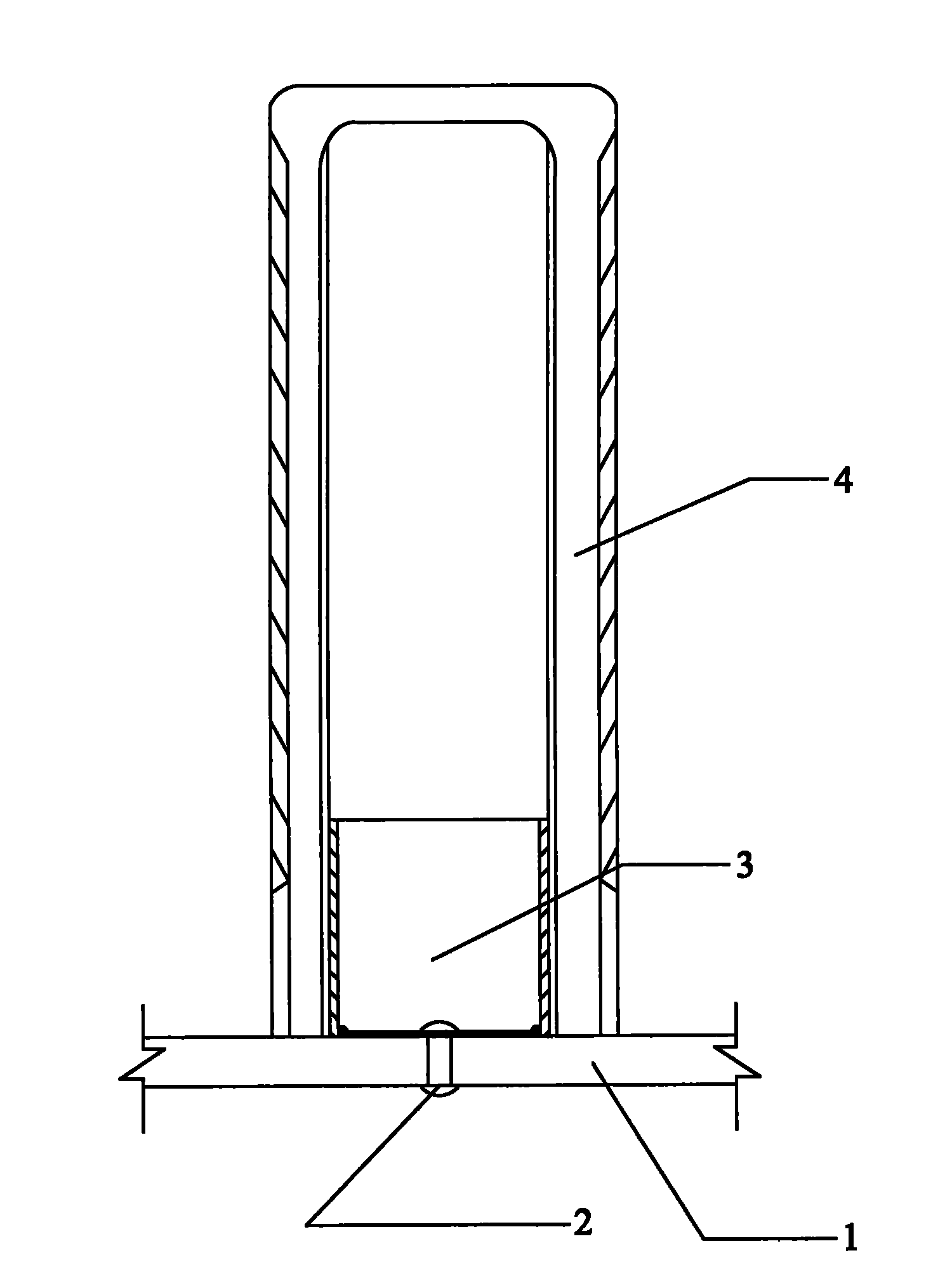

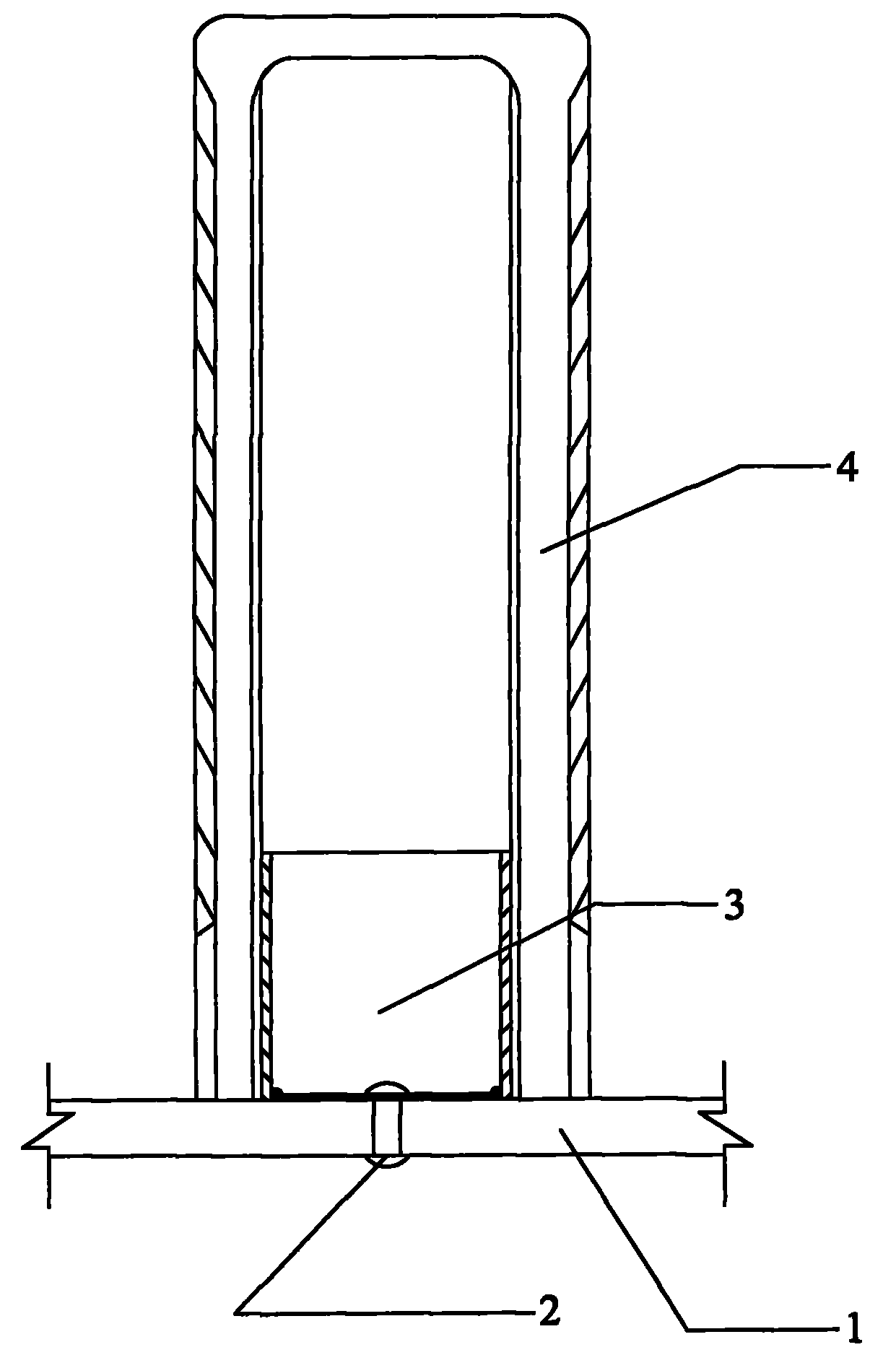

Device and method for positioning casing pipe

A casing and positioning technology, which is applied to ceramic molding machines, manufacturing tools, molds, etc., can solve problems such as difficulty in changing casings, limitation of the scope of application of molded concrete components, and damage to the bottom mold of concrete components, and achieve minimal damage. , Eliminate repetition and difficulty, and improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The term "pretensioning process" as used herein is a method of molding prestressed concrete elements, referring to a construction method in which steel is tensioned on a pedestal and then concrete is poured to form a prestressed concrete element. The process includes stretching the steel bar with a predetermined tension and fixing the two ends of the steel bar on the pedestal or steel mold with clamps; supporting the mold and pouring concrete; after the concrete member reaches the predetermined strength, releasing the prestressed steel bar. The reinforcement and thus the reinforcement shrinks (ie is called tension) so as to create a pre-stress in the concrete member. In particular, the long-line pedestal method (also known as the long-line method) can be used for concrete members produced by the pre-tensioning process, and the length of the long-line pedestal is usually 50-150m. In the pre-tensioning process of the long-line pedestal, steel bars are stretched along the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com