Production method of ferric stainless steel

A production method, stainless steel technology, applied in the field of metallurgy, can solve the problems of reduced metal yield, large impact of production cost fluctuations, high alloy loss, etc., to reduce secondary emissions and environmental pollution, improve metal yield and energy Effectiveness of utilization efficiency and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments. Process method of the present invention except following content, all the other all adopt the routine method or device of this field. Unless otherwise specified, the terms involved in the present invention have meanings commonly understood by those skilled in the art.

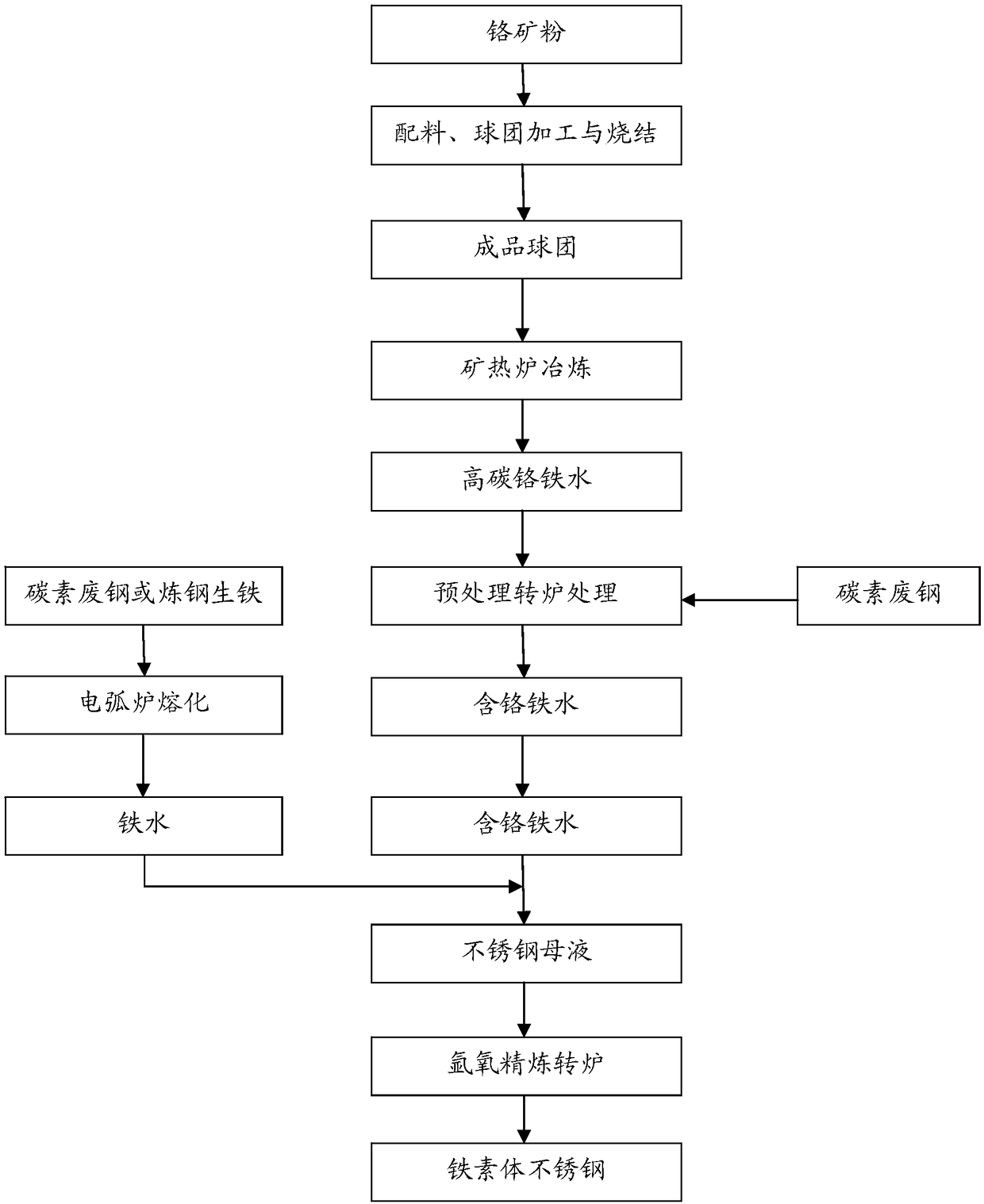

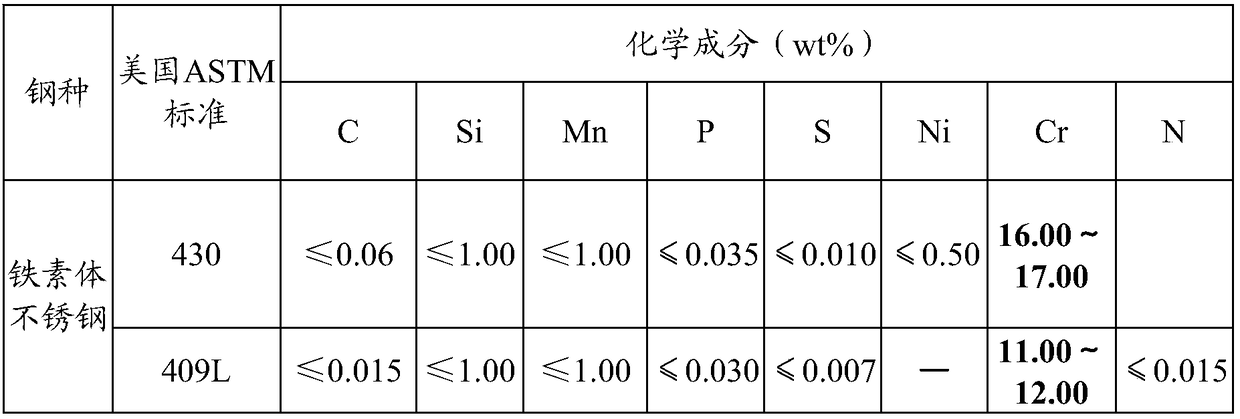

[0046] like figure 1As shown, the production method of the present invention for directly producing ferritic stainless steel from chromite includes the steps of preparing high-carbon chromium hot metal, preparing chromium-containing hot metal, preparing molten iron, preparing stainless steel mother liquor and preparing ferritic stainless steel, as follows.

[0047] (1) Preparation of high-carbon ferrochromium: the raw material chromium ore powder is batched and made into pellets, and then preheated and sent to a submerged a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com