Node connection method for circular steel tube concrete column and reinforced concrete shear wall

A technology of reinforced concrete and concrete columns, applied in the directions of columns, piers, pillars, etc., can solve the problems of large on-site welding workload, complicated construction, poor connection bearing capacity, etc., to achieve convenient construction and improve the ability to resist rare loads. , the effect of high lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention will be described with reference to the accompanying drawings.

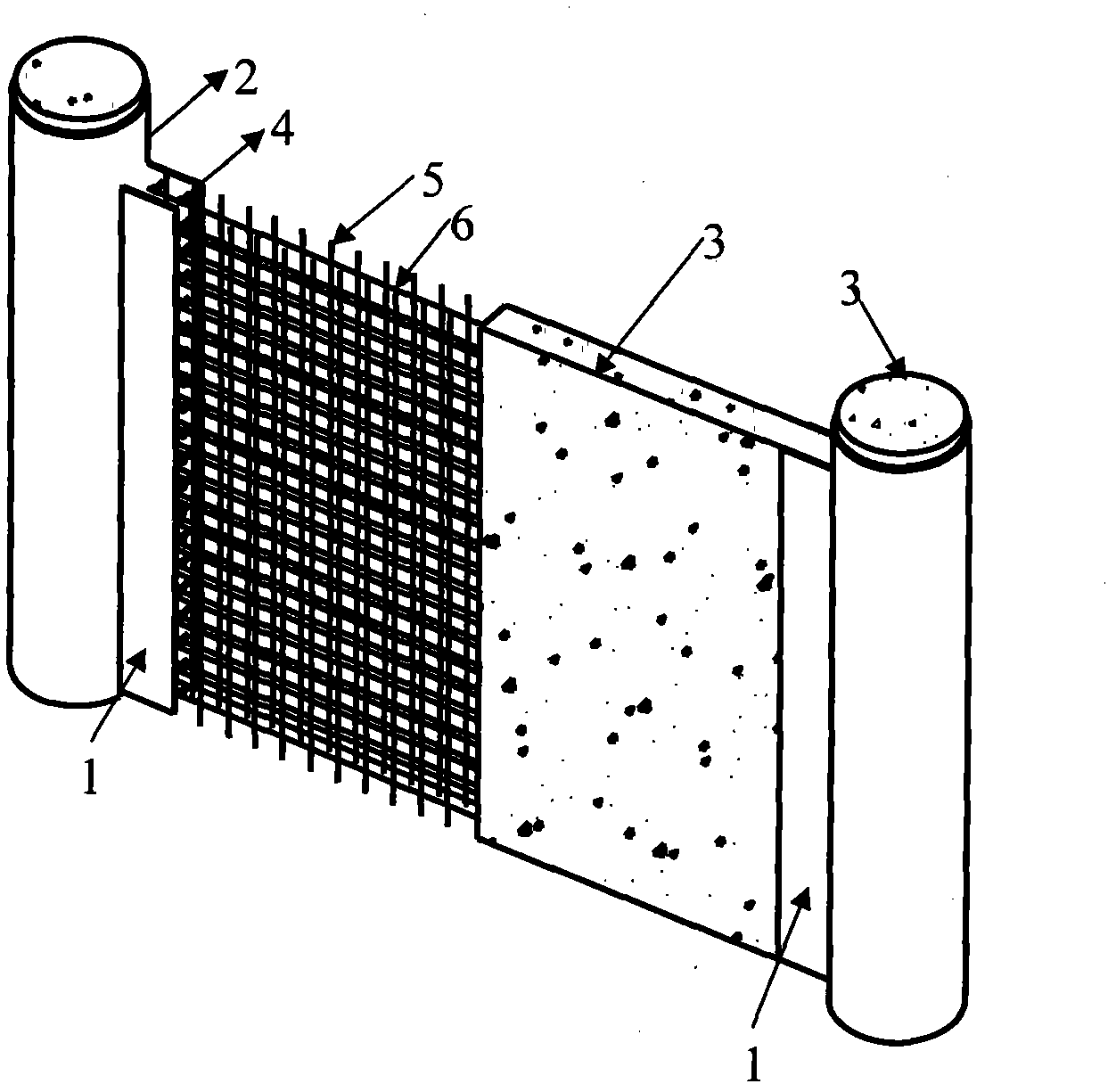

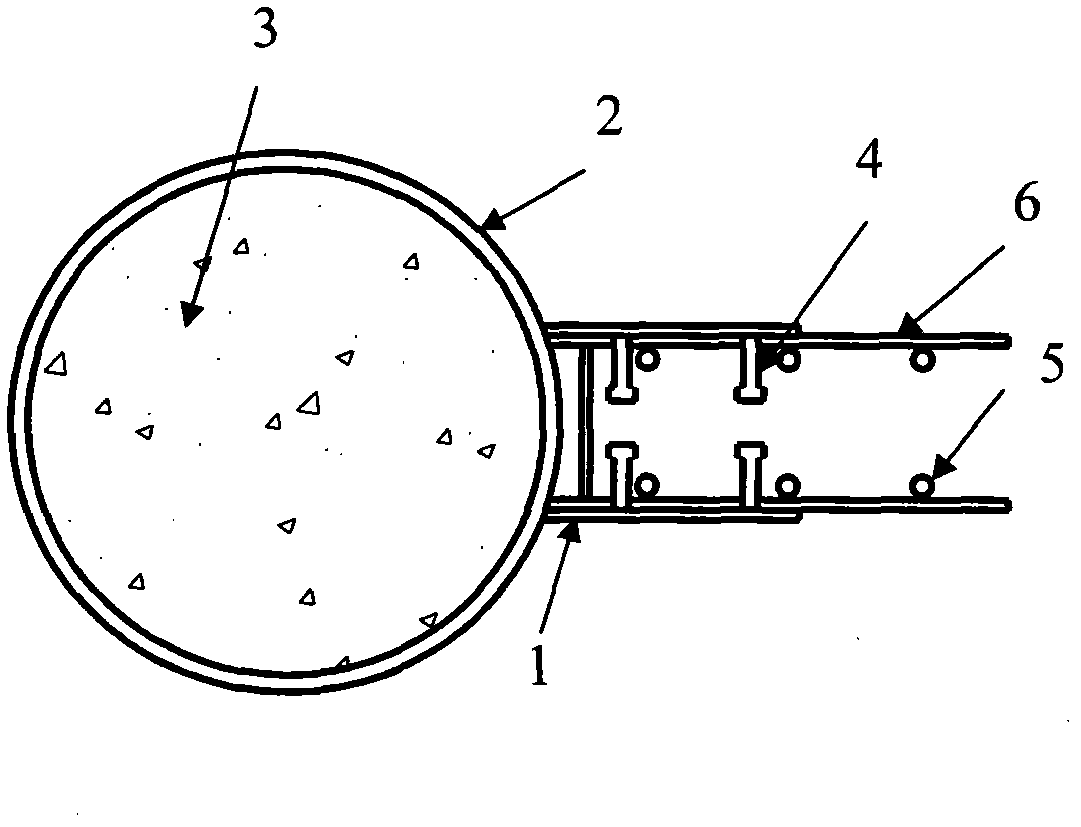

[0014] First, weld the shear connector 2 on the inner side of the connecting steel plate 1. The shear connector 2 is arranged in at least one row along the longitudinal direction of the connecting steel plate 1. The shear connector 2 can be made of Q235 or Q345 steel studs, channel steel or bent bar members. . Then, the connecting steel plate 1 welded with the shear connector 2 and the steel pipe 3 of the circular steel pipe concrete column are connected by welding. At the construction site, after the steel pipe 3 in the circular steel tube concrete column is installed and positioned, the longitudinal reinforcement 4 in the reinforced concrete shear wall, the U-shaped horizontal distribution reinforcement 5 at the end and the horizontal distribution reinforcement 6 at the non-node are arranged, and the reinforcement is carried out. Binding and positioning, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com