Construction method for plugging end of prestress pilaster steel strand of concrete silo

A construction method and a technology of attaching pilasters, which are applied in the directions of construction, building structure, and construction material processing, can solve the problems of labor and material costs and difficulty in construction, and achieve the goals of convenient construction, improved visual quality, and material saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

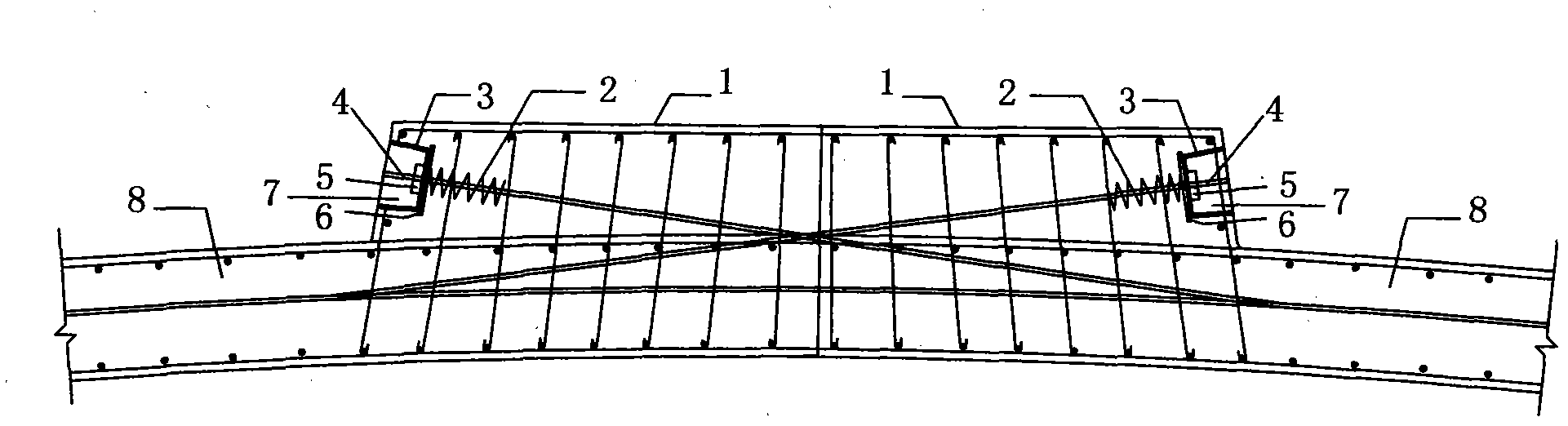

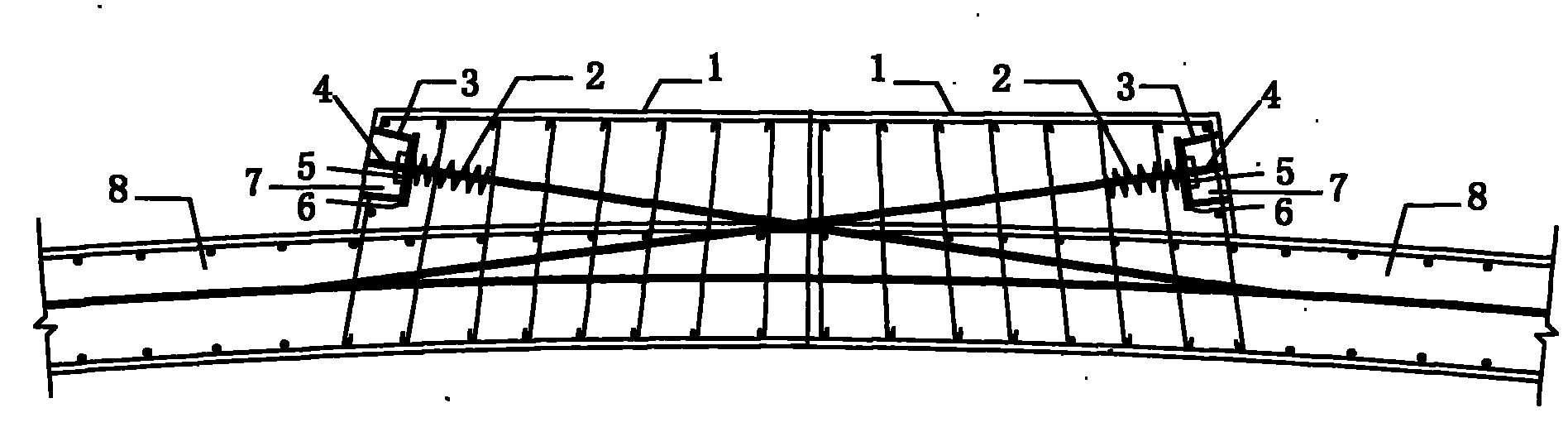

[0008] With reference to the accompanying drawings, the pilaster 1 is poured outside the warehouse wall 8, and one end of the steel strand 4 is connected to the prestressed steel strand in the warehouse wall 8. The pilaster 1 is installed with a cavity form 3 during slipform construction, and the seal is reserved. Plug the groove, the other end of the steel strand 4 with the spiral rib 2 passes through the bottom surface of the groove of the cavity mold 3 attached to the wall column 1, take out the cavity mold 3 after the concrete of the wall column 1 is solidified, and pass through the end of the steel strand 4 After passing the anchor backing plate 6 attached to the bottom surface of the groove, it is fixed with the anchor 5. After the prestressed tension, the connecting bars between the wall column 1 and the warehouse wall 8 are fixed, and then the concrete 7 is used to seal the groove. groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com