Method for storing gas by using abandoned tunnel

A roadway and gas technology, applied in the direction of earth drilling, mining equipment, mining equipment, etc., can solve the problems of large concentration changes, changes in gas extraction volume, and difficulty in power generation of low-concentration gas, to achieve strong anti-knock and improve gas utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

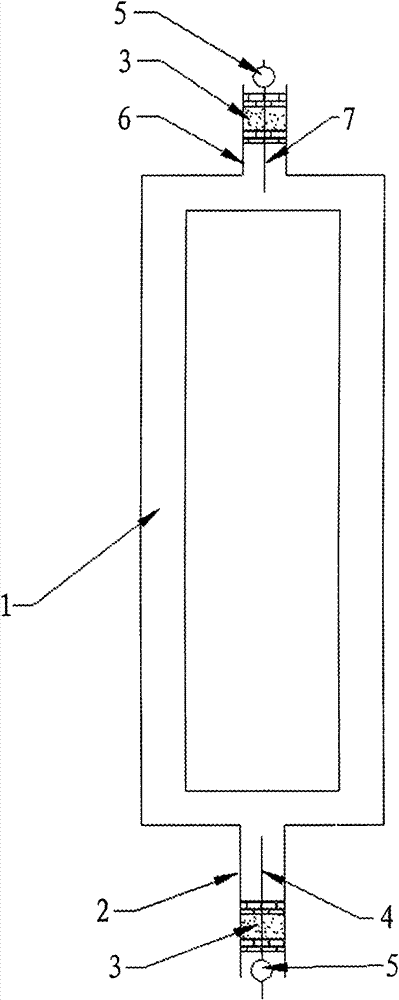

[0038] Combine below figure 1 The method of the present invention will be further described in detail, but the present invention is not limited to the following.

[0039] According to the different conditions of abandoned roadways in various mines, roadways with good conditions are selected, and rock formation roadways are preferred, followed by coal seam roadways; roadway roofs are in good condition and support conditions are good, and coal seam roadways are preferably supported by shotcreting. It is best that there is no deformation or caving of the roadway caused by ground stress; the rock formation or coal seam that the roadway passes has no geological structures such as faults that affect the sealing of the roadway; A spark that causes gas to ignite or explode.

[0040] All the exits 2 and 6 connected to the roadway 1 are all built with waterproof, fireproof and explosion-proof airtight walls 3, and the roadway 1 is completely isolated from the outside world to form a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com