Porous electrode substrate and manufacturing method thereof, film-electrode combination and solid high-polymer fuel cell

A technology of electrode substrate and manufacturing method, applied in solid electrolyte fuel cells, battery electrodes, final product manufacturing, etc., can solve problems such as flooding, increased condensation, etc., and achieve the effect of low apparent thermal diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

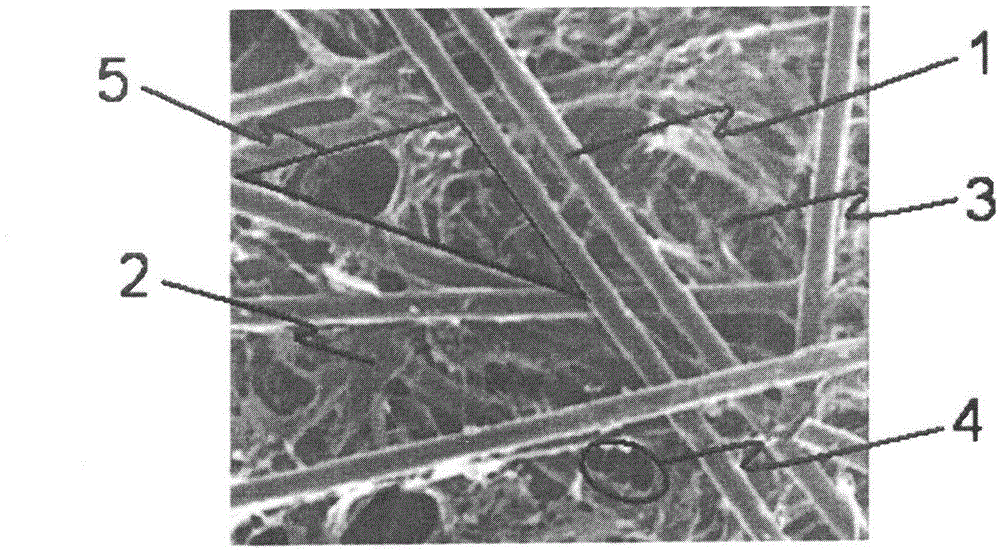

Image

Examples

Embodiment 1

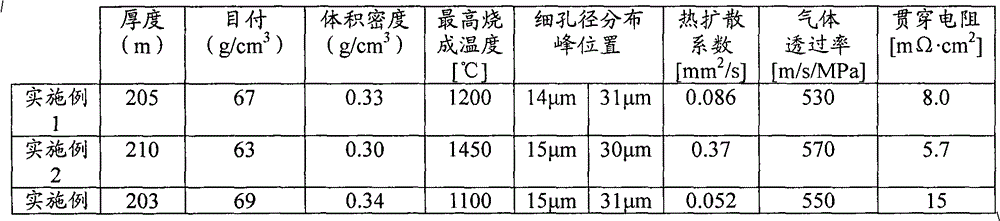

[0117] Short fiber bundles of polyacrylonitrile (PAN)-based carbon fibers having an average fiber diameter of 7 μm and an average fiber length of 3 mm were uniformly dispersed in water in a slurry tank of a wet-type short-wire continuous papermaking device to be opened. When the short carbon fibers are sufficiently dispersed, short fibers of polyvinyl alcohol (PVA) (manufactured by Kuraray Co., Ltd., trade name: VBP105-1, cut length 3mm) as a binder are uniformly dispersed and fibrils The polyethylene pulp (manufactured by Mitsui Chemicals, Inc., trade name: SWP, freeness: 450 ml) was sent out at 18% by mass and 77% by mass relative to short carbon fibers. Make the sent web pass through the short mesh plate, and dry it with a desiccant to obtain a gram weight (flat weight) of 43g / m2 , carbon fiber paper A with a length of 100m.

[0118] Next, the carbon precursor fiber resin was attached to the carbon fiber paper A by a kiss coat method. Specifically, the carbon fiber paper A...

Embodiment 2

[0122] A porous electrode substrate was obtained in the same manner as in Example 1, except that the temperature for heating in a nitrogen atmosphere for 5 minutes was set to 1450° C. in the carbonization treatment performed in a continuous firing furnace. Table 1 shows the evaluation results of the obtained porous electrode substrates.

Embodiment 3

[0124] A porous electrode substrate was obtained in the same manner as in Example 1, except that the temperature for heating in a nitrogen atmosphere for 5 minutes was set to 1100° C. in the carbonization treatment performed in a continuous firing furnace. Table 1 shows the evaluation results of the obtained porous electrode substrates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com