Fixing bracket and radiating device using same

A technology of a heat sink and a fixing frame, which is applied in the fields of electric solid-state devices, cooling/ventilation/heating transformation, semiconductor/solid-state device components, etc. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

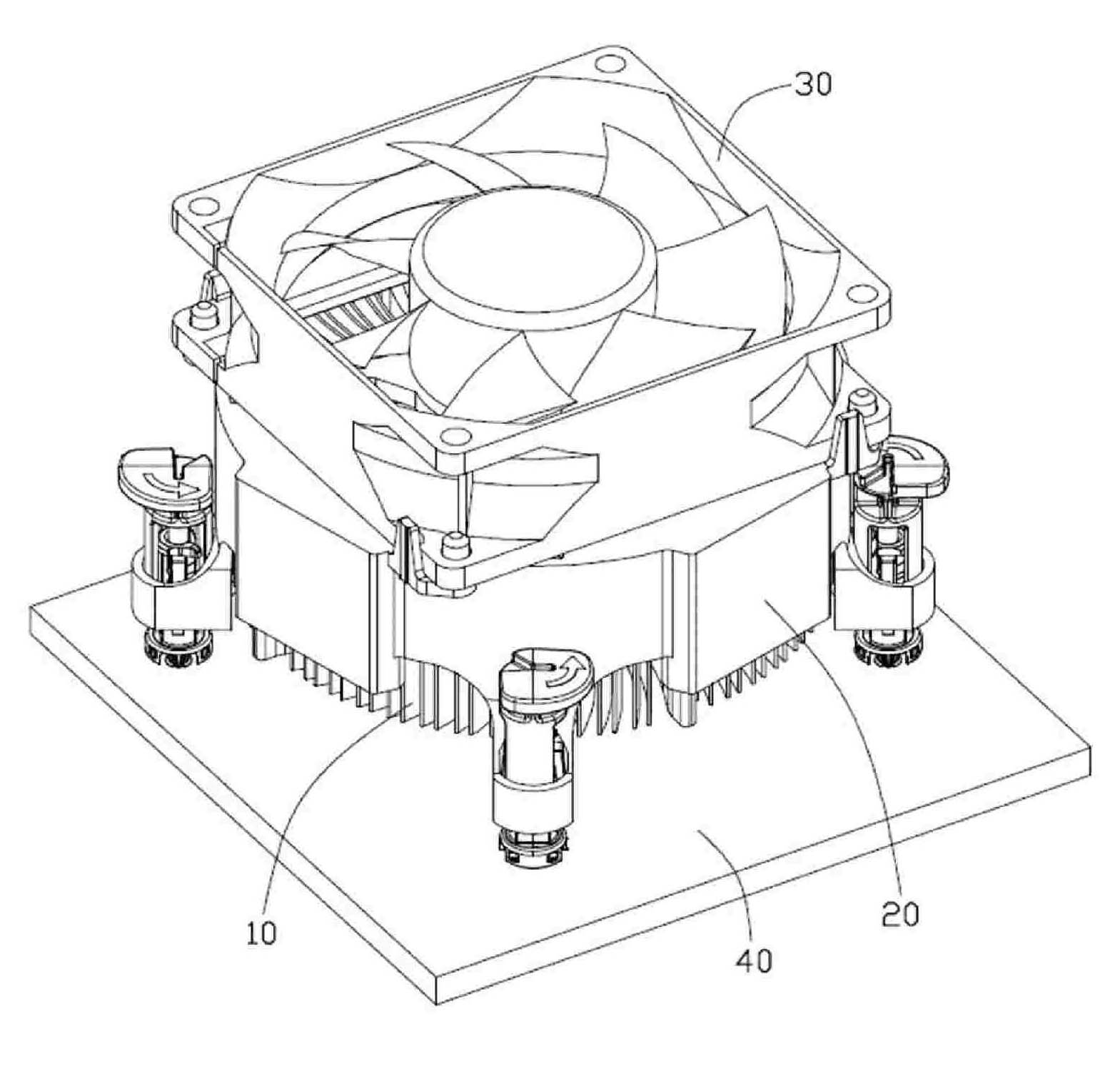

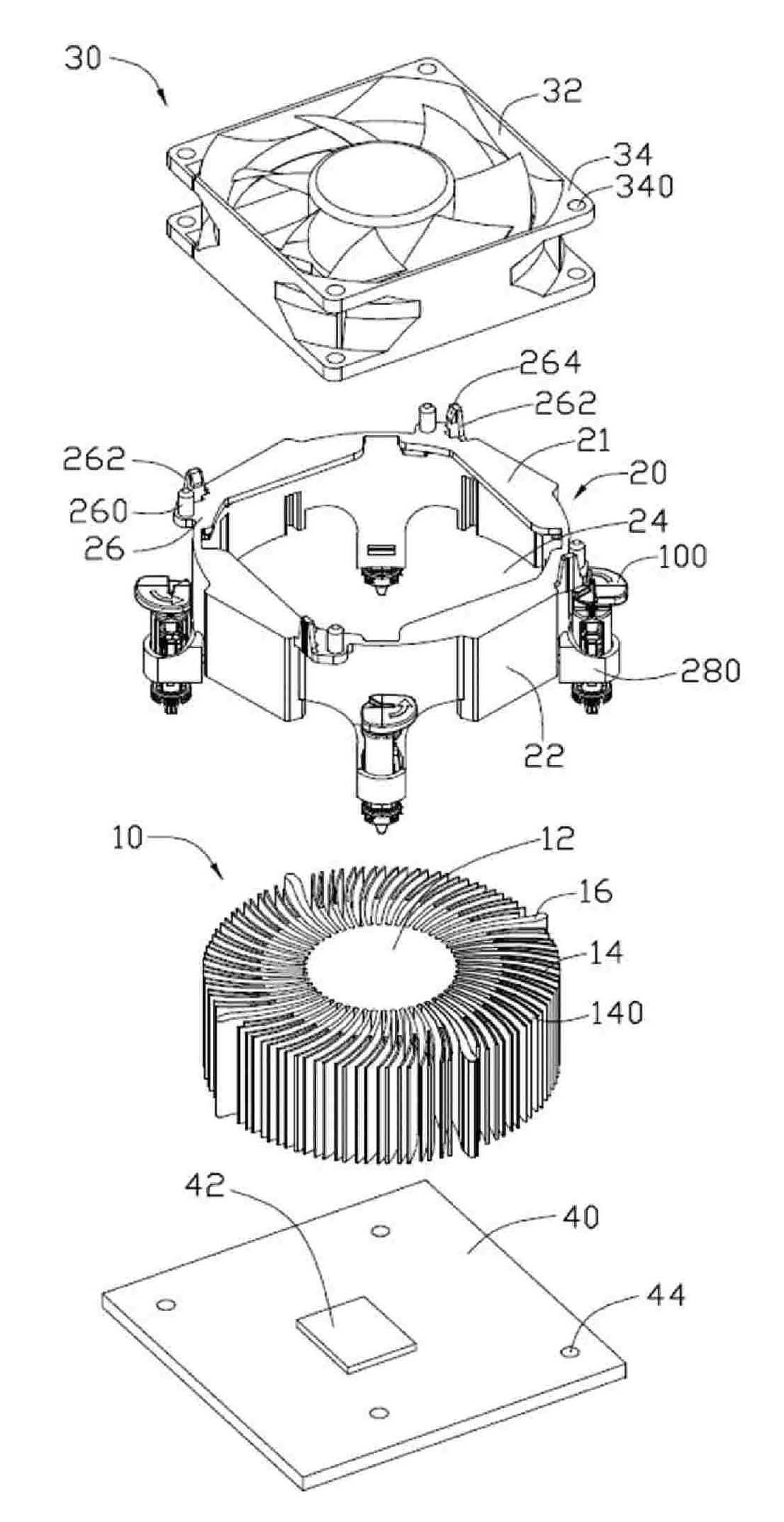

[0017] see figure 1 and figure 2 The heat dissipation device in some embodiments of the present invention can be used to dissipate heat from a heat-generating electronic component 42 (such as a computer CPU) mounted on a circuit board 40. The heat dissipation device can include a heat sink 10 for fixing the heat sink 10 to a fixture 20 on the circuit board 40 . In some embodiments, a fan 30 is installed on the top of the fixing frame 20 to drive the air around the heat sink 10 to perform forced convection, so as to improve heat dissipation efficiency.

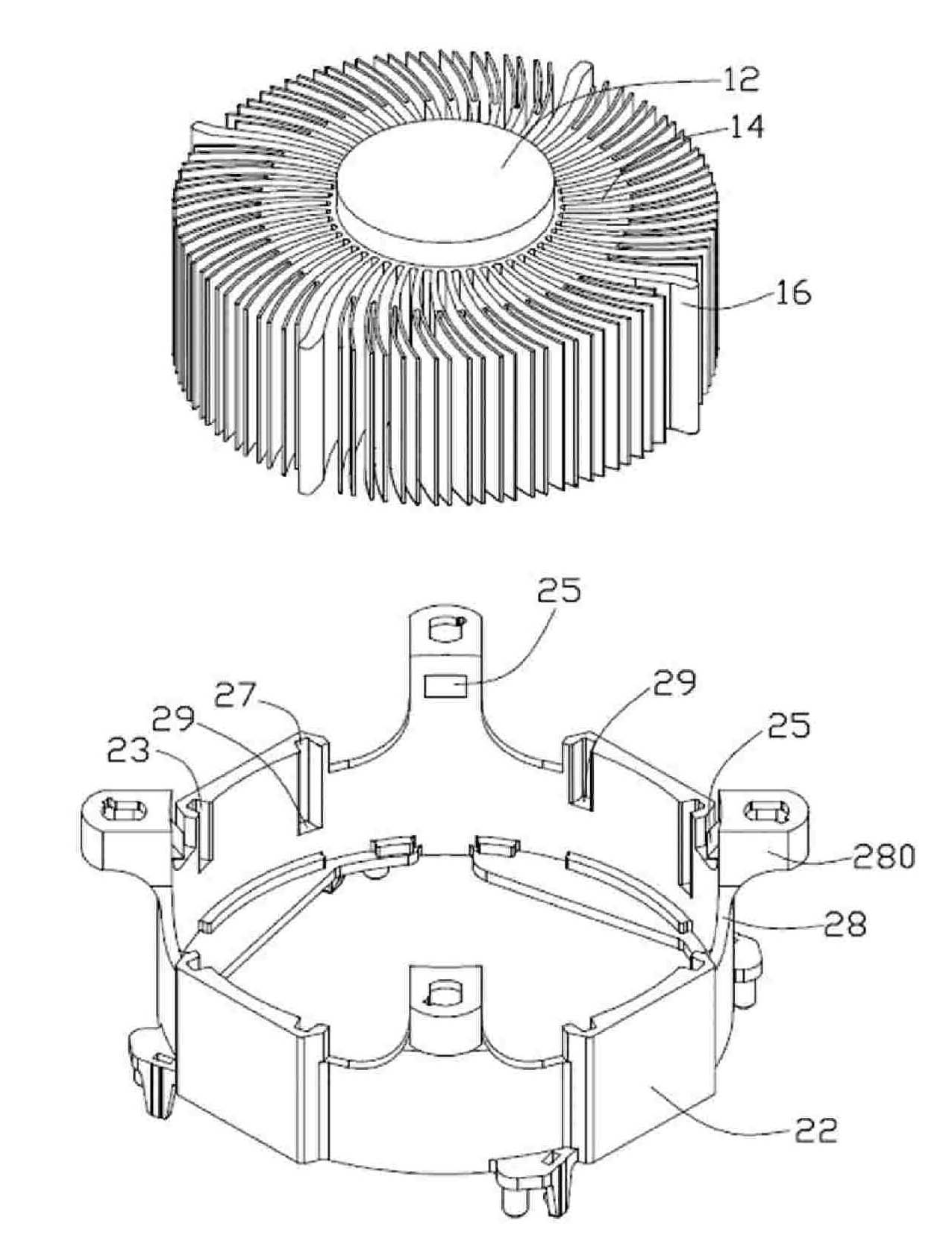

[0018] The radiator 10 mentioned above can be cylindrical in some embodiments, and adopts relatively low-cost extruded (for example, aluminum extruded, copper extruded) molding, and this radiator 10 comprises a thermal conduction column 12 and is formed by the circumference of the thermal conduction column 12 outwards. Several cooling fins 14 extending divergently. The heat conduction column 12 is arranged in a cylindrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com