Shaping device for preparing bent tube by virtue of differential-velocity extrusion of dual male dies

A forming device and double punch technology, applied in the direction of metal extrusion dies, etc., can solve the problems of limited bending angle and direction of pipe fittings, inability to achieve arbitrary bending, wrinkled cross-section, etc., to improve the length range and wall thickness. Wrinkled, cross-sectional distortion-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

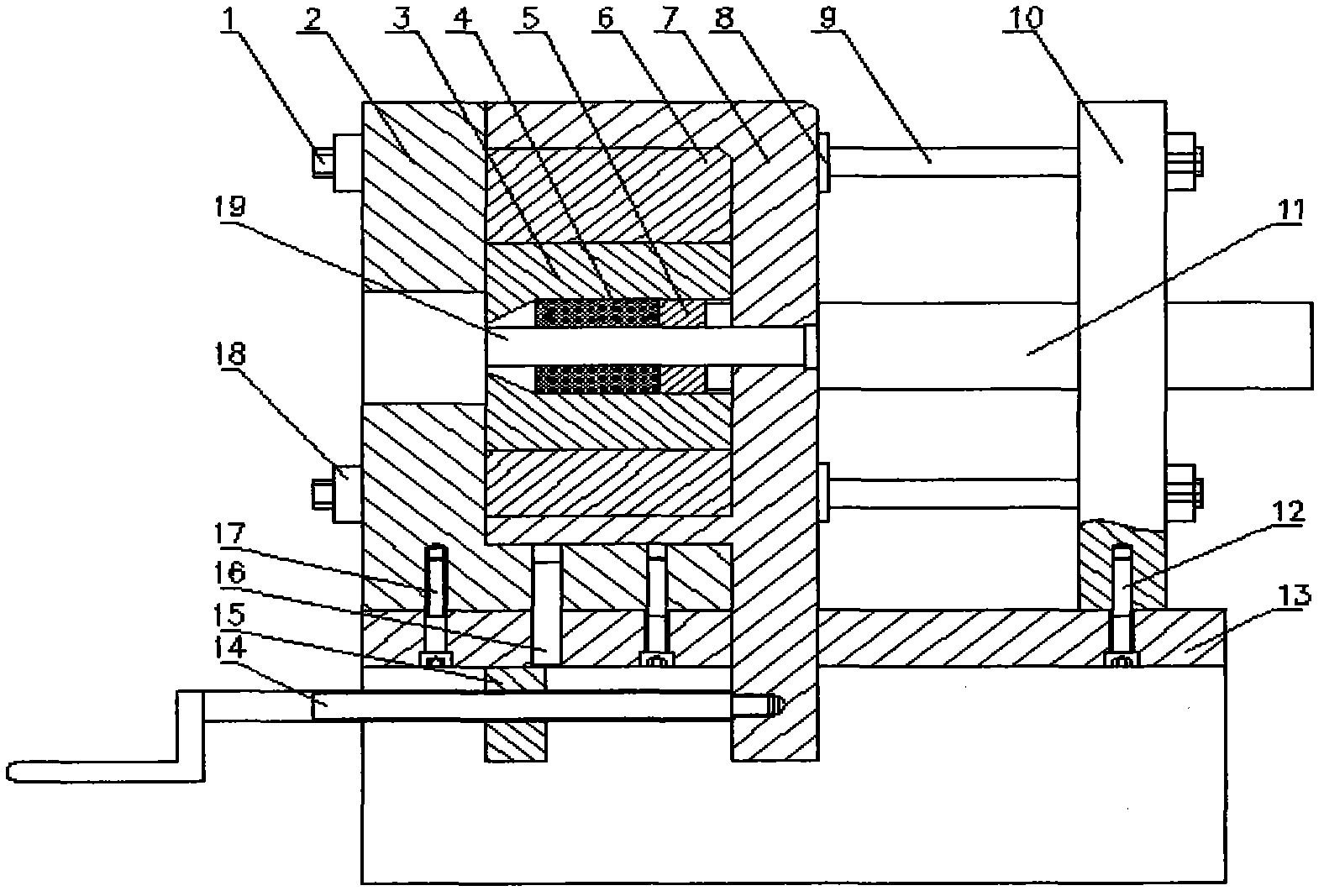

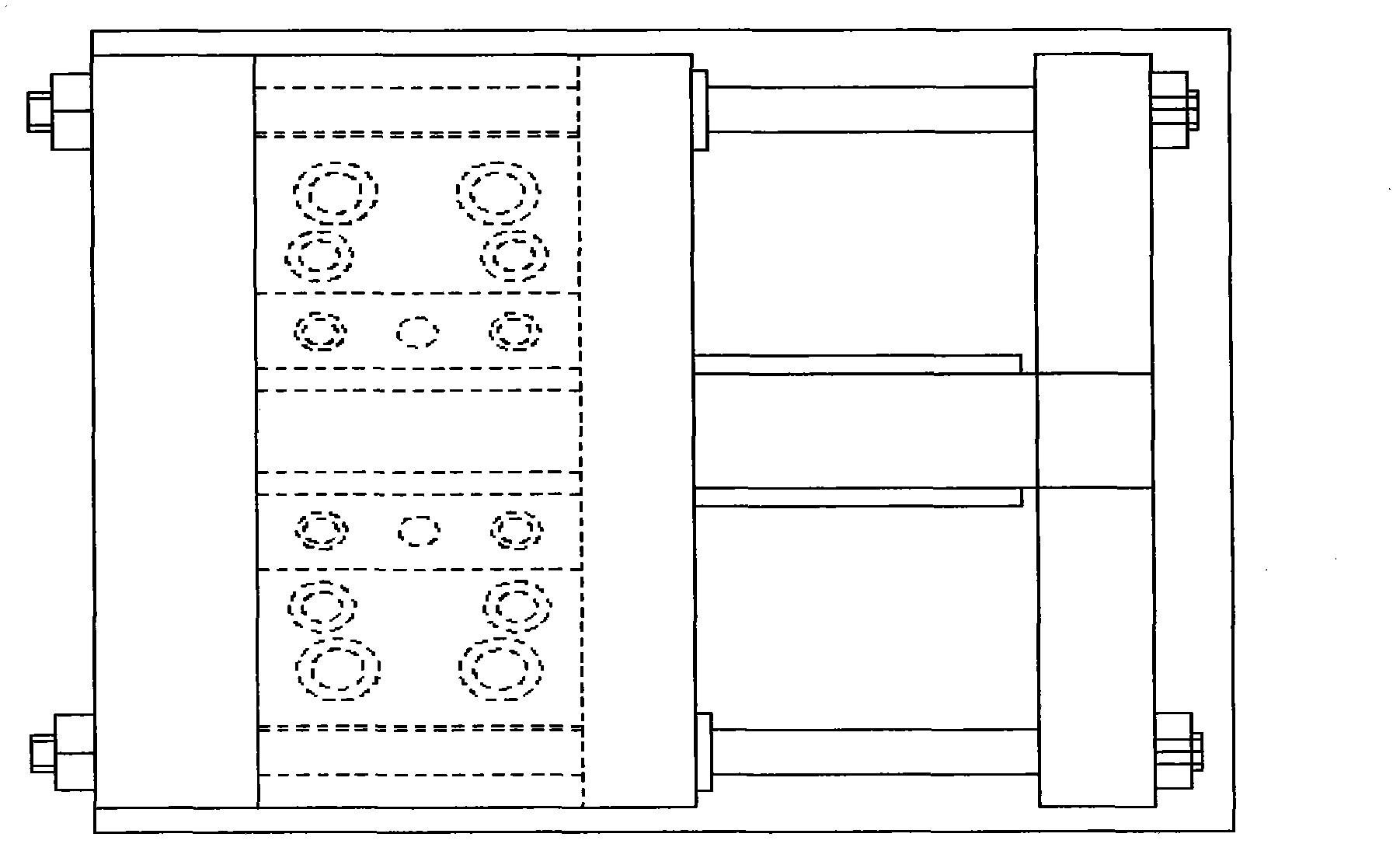

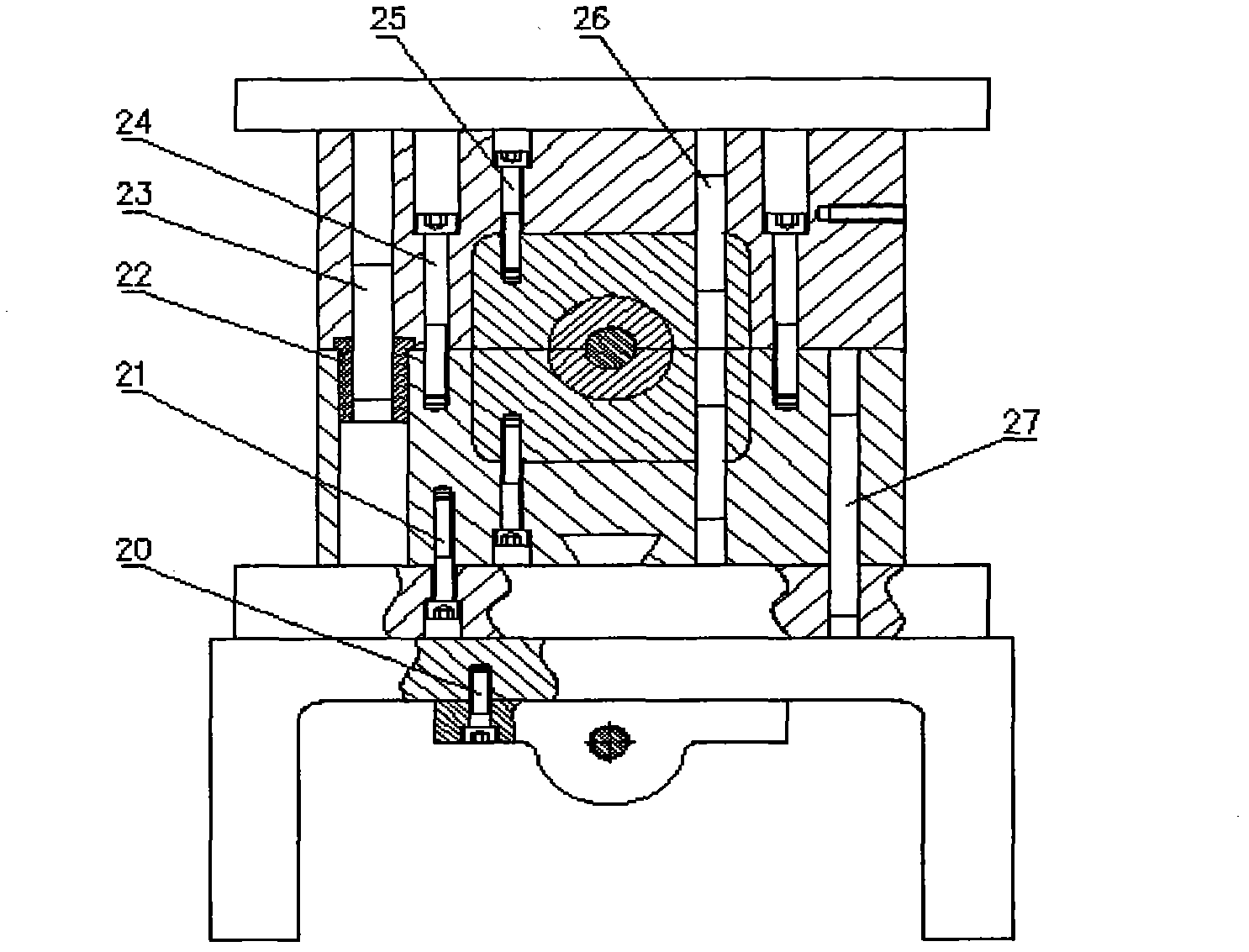

[0023] Double-convex differential extrusion forming device for preparing pipe bending parts. The extrusion forming device includes a mold forming part, a mold fixing part and a guide part; the mold forming part includes die inserts 1 and 2, a mandrel 19 and an extrusion block A and B, the die inserts 1 and 2 are respectively fixed on the die fixing plates 1 and 2 by screws 24 and pins 25, the punch is composed of two semicircular cylinders, the die is composed of die inserts, and the core The geometric center line of the shaft and the punch is on the same straight line after the mold is assembled; the fixed part of the mold includes the base fixing plate 2, the support seat 13, the slide plate 7, the die fixing plate 6, and the die fixing plate 6-2 has a dovetail groove , the slide plate 7 and the die fixing plate are sliding fit, the die fixing plate 6-2 is fixed on the base fixing plate 2 through the screw 21 and the pin 27, and the base fixing plate 2 is fixed on the support...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com