Lift adjusting device

A technology of lifting adjustment and adjusting shim, applied in the direction of lifting device, lifting frame, etc., can solve the problem of undiscovered adjustment equipment, etc., and achieve the effect of simple structure, easy operation and high adjustment rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

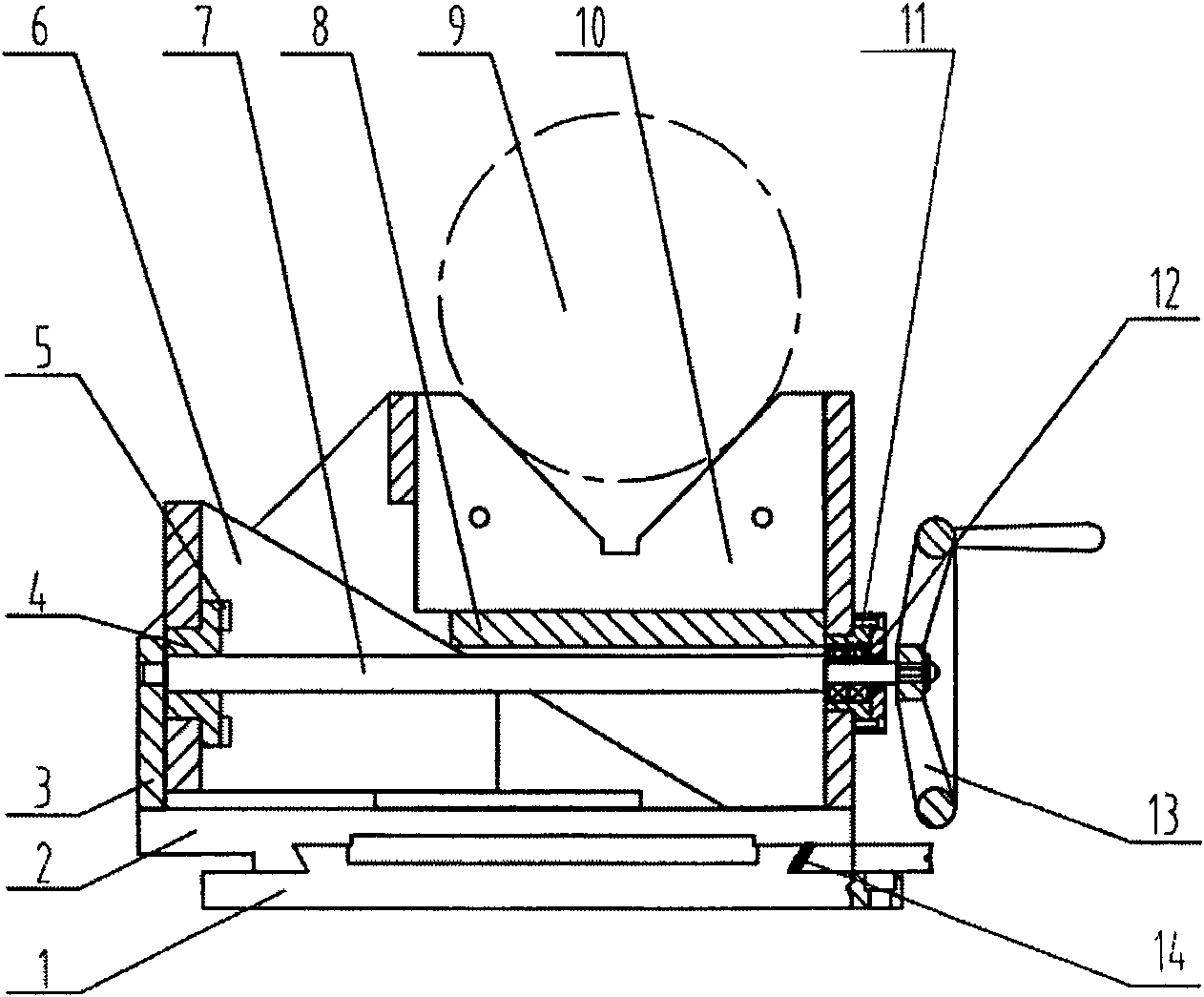

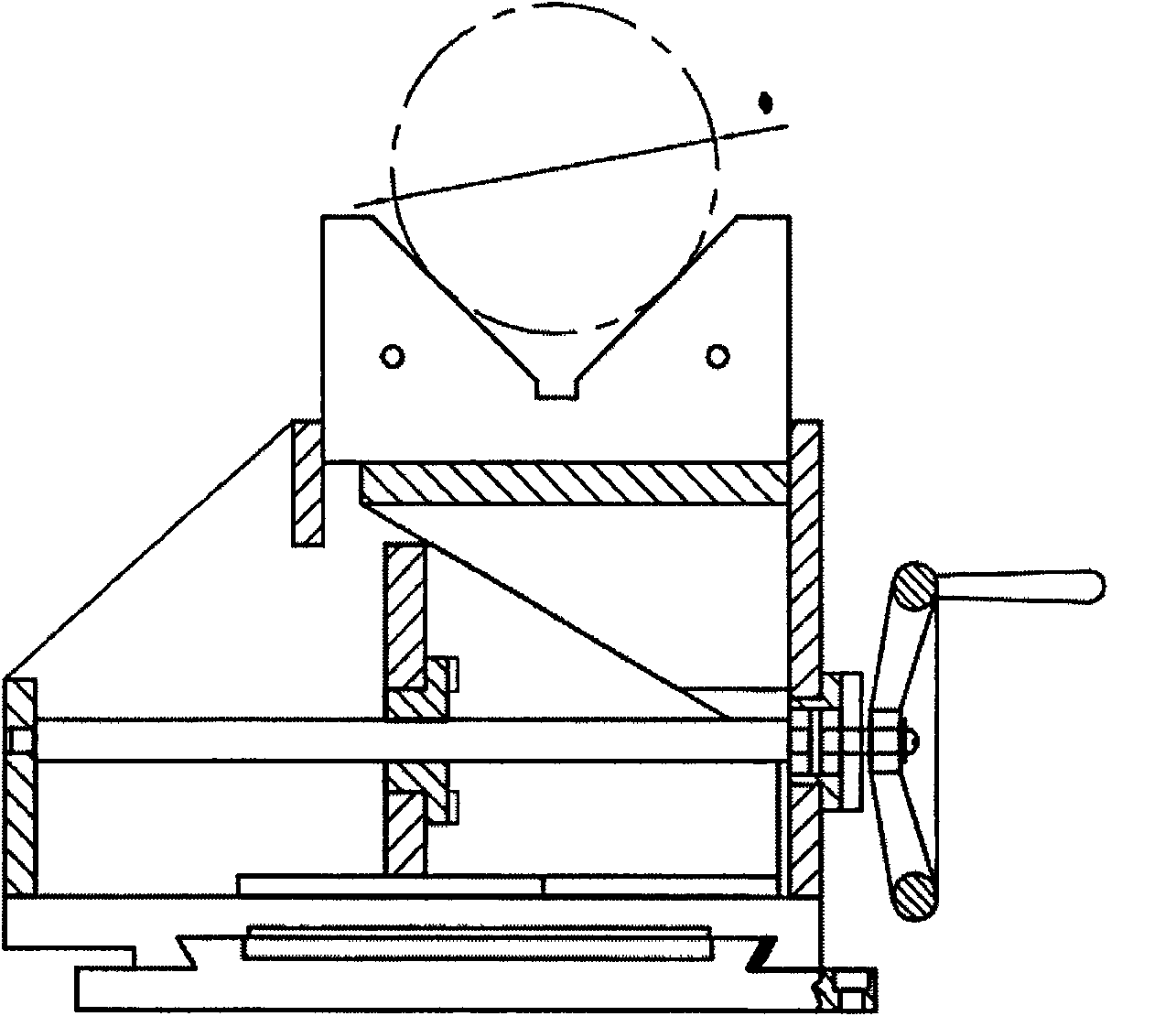

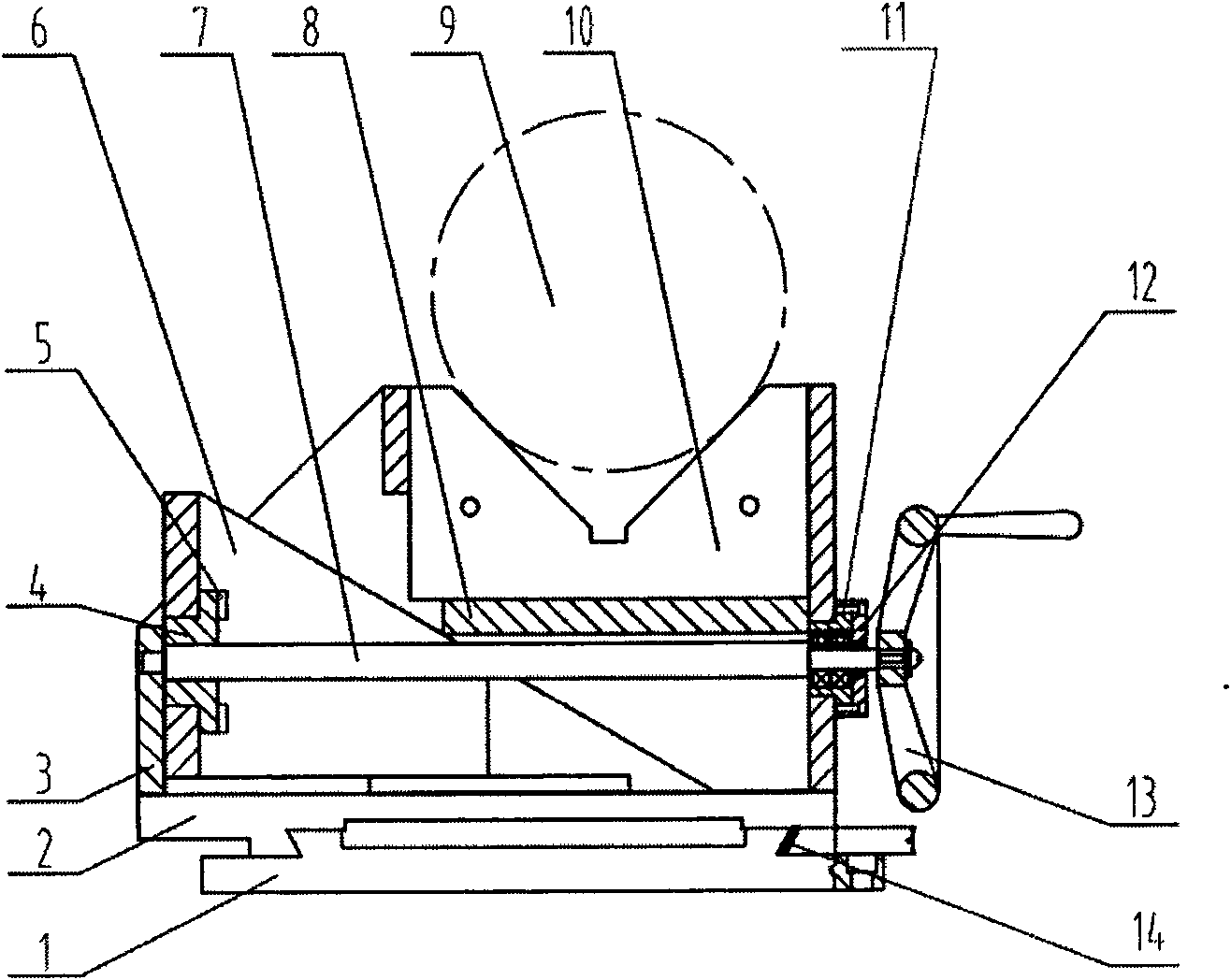

[0016] The invention relates to the mechanical field, in particular to a lifting adjustment device. By changing the installation method of the device, it can be used as a position adjustment device for different purposes such as assembly, processing, and measurement of parts. It is mainly used in precision instruments or equipment that need to adjust the assembly, processing position or measure the position of parts, such as robot joint assembly, etc. . This article mainly introduces the present invention by taking the vertical adjustment of the center height of parts as an example.

[0017] This embodiment is a novel lift adjustment device, which includes three parts: a base, a vertical movement lift adjustment device and a clamp. in:

[0018] like figure 1 As shown, the base is composed of a dovetail bottom plate 1, a dovetail upper plate 2 and a guide rail adjustment gasket 14, and is located at the bottom of the entire lifting adjustment device. The dovetail base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com