Spinning-in pull rod device for false twist texturizing machine

A technology of false twist texturing machine and tie rod device, which is applied in the direction of textiles and paper making, can solve the problems of complex structure, inconvenient installation and adjustment, and poor stability of the tie rod device, and achieve the reduction of assembly process difficulty and processing cost, simple and easy Effect of processing and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

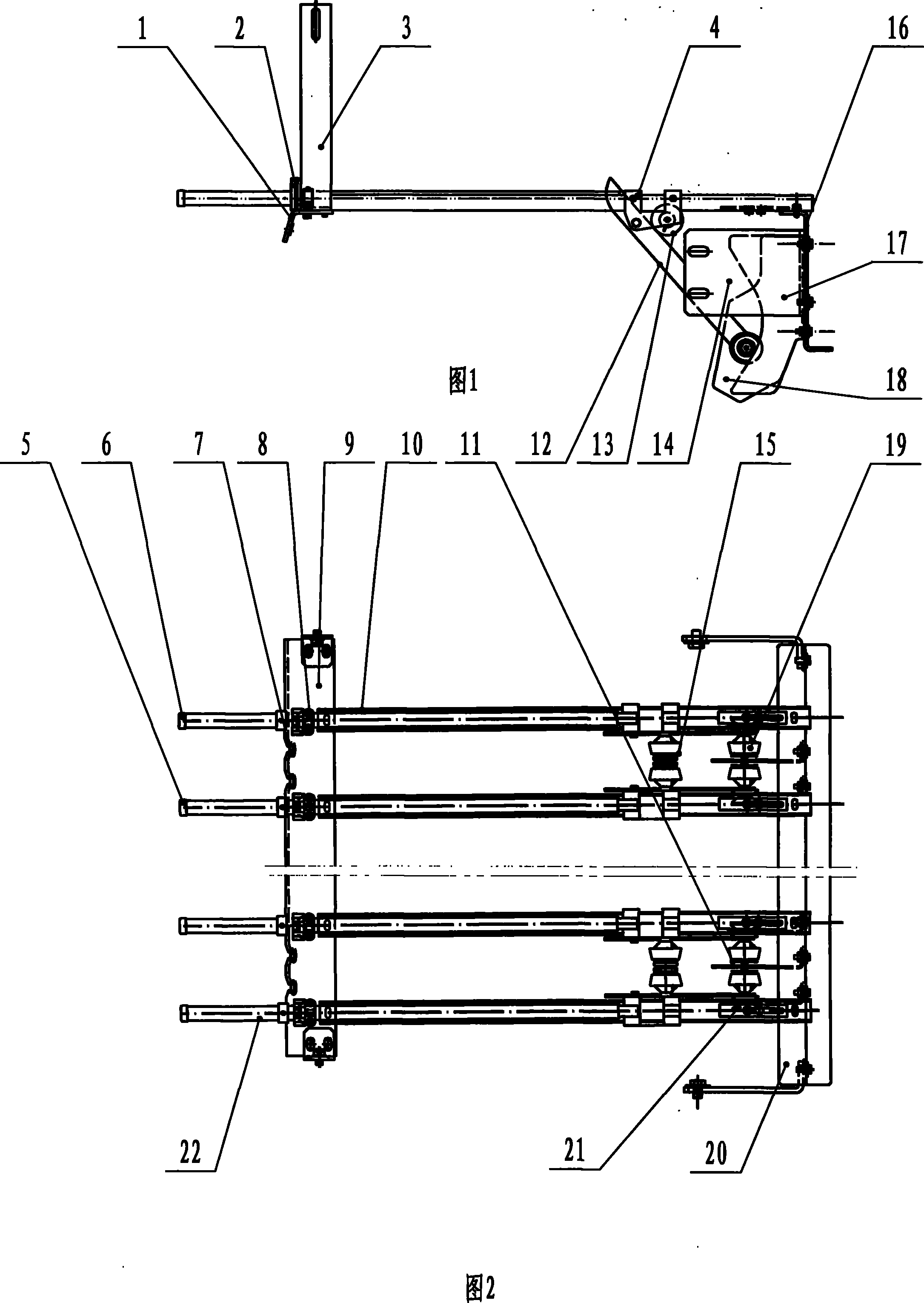

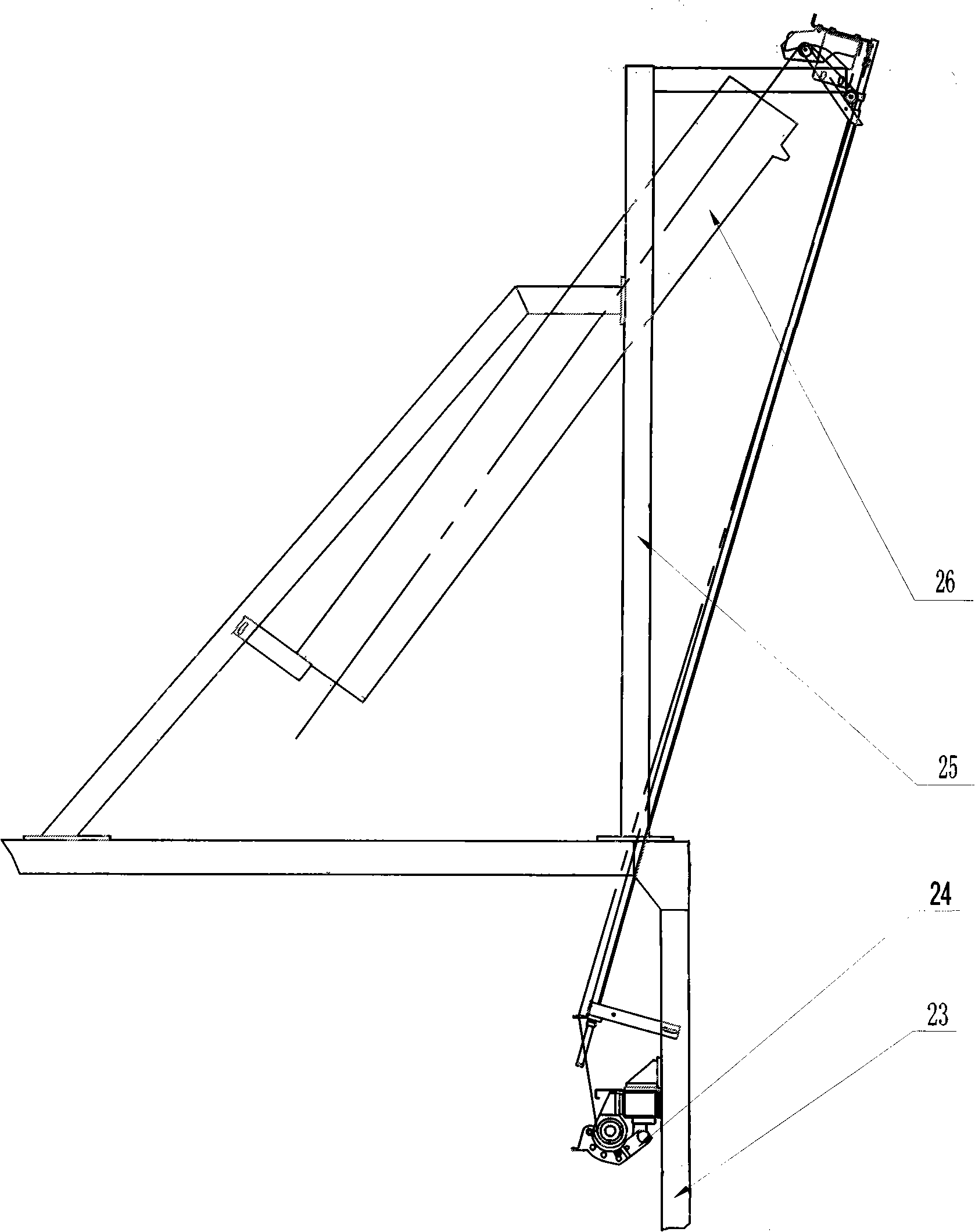

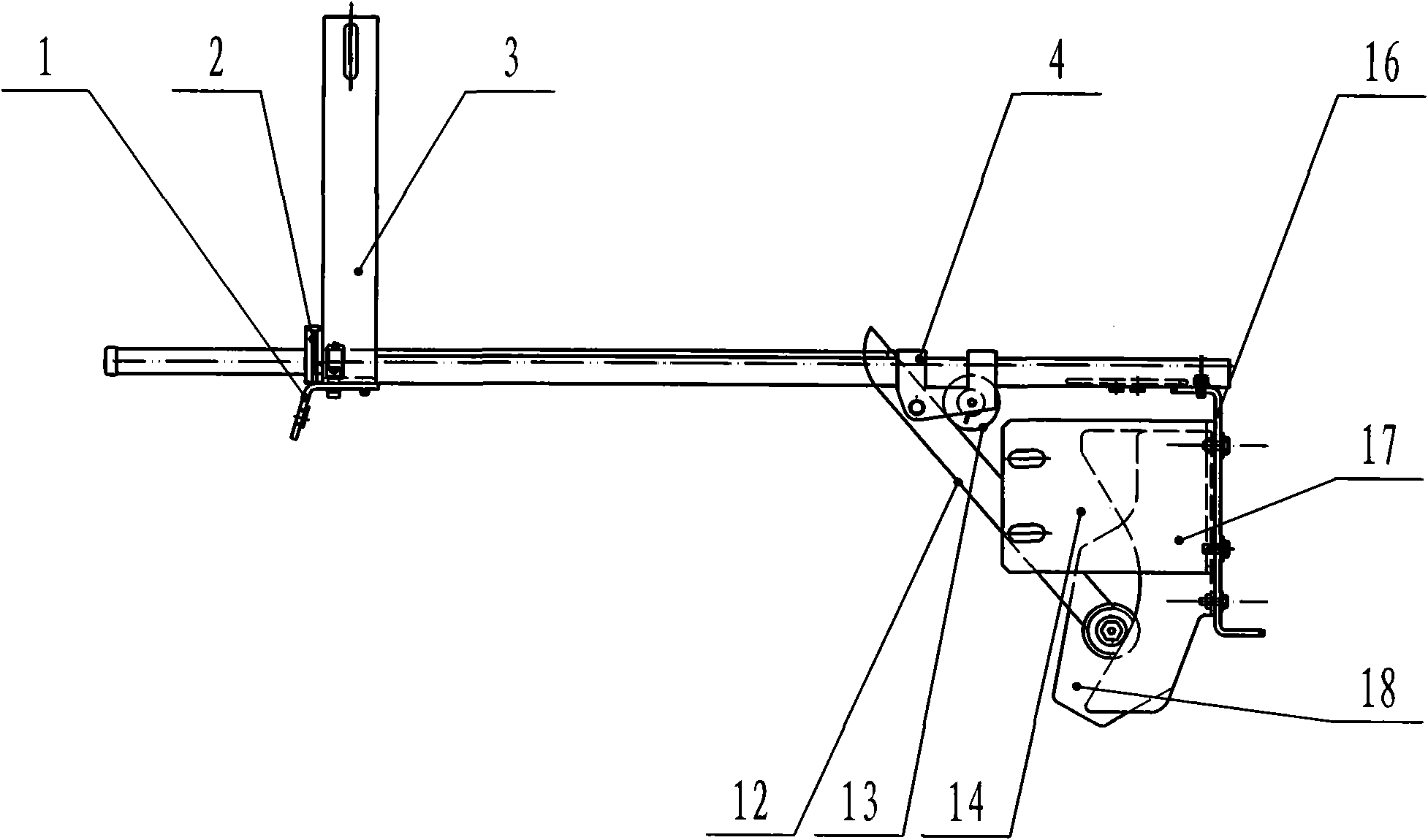

[0010] A threading rod device of a false twist texturing machine, which includes a guide wire seat plate device 1, a spring steel clip 2, a seat plate 3, a supporting leg 14, a left threading rod device 5, a right threading rod device 6, a clip 8, The guide rail seat device 20, the six left threaded pull rod devices 5 and the six right threaded thread pull rod devices 6 are fixed on the guide wire seat plate device 1 and the guide rail seat device 20, and the guide wire seat plate device 1 and the guide rail seat device 20 pass through the seat Plate 3, supporting pin 4 are fixed on lower frame 24, upper frame 25; Guide wire seat plate device 1 comprises guide wire seat plate 9, spring steel clamp 2 and guide wire porcelain part 7, guide wire seat plate 9 and spring steel The clamp 2 is connected, and the guide wire ceramic part 7 is arranged on the guide wire seat plate 9; the left pull rod device 5 and the right pull rod device are the same, and they respectively include a pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com