Radial-inserting and radial-throttling type throttler and balance sieve tube employing same

A choke and flow-restricting technology, which is used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of unfavorable processing, complex product structure, unfavorable oil well adjustment, etc., and achieve the effect of good sand control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

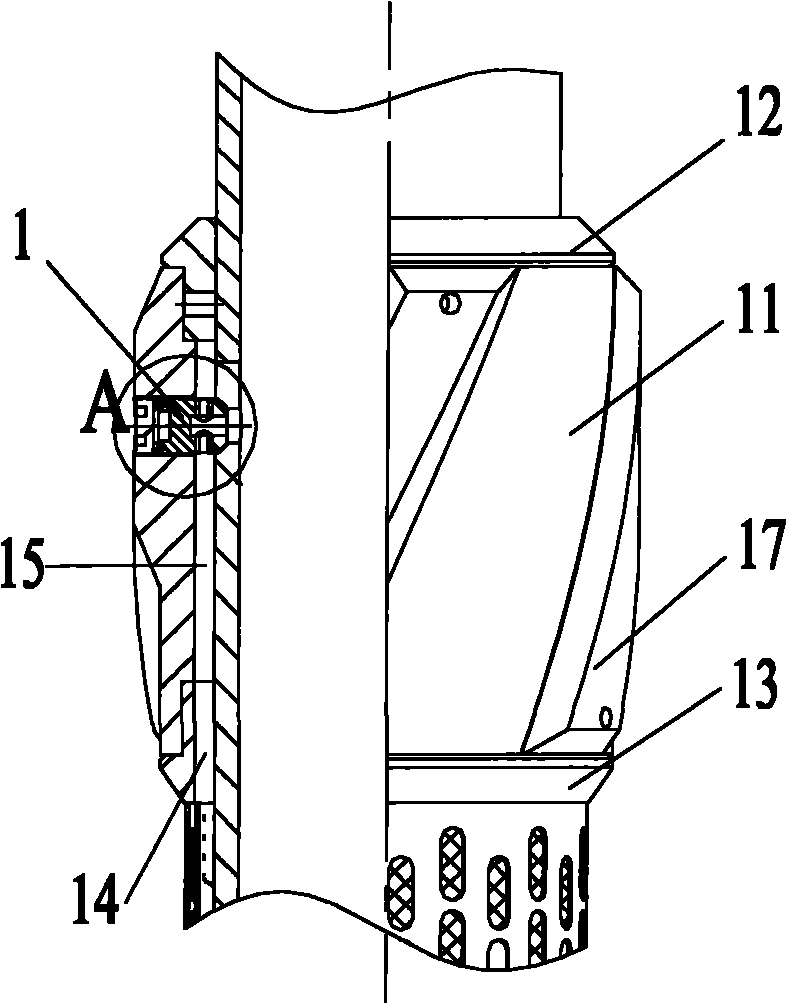

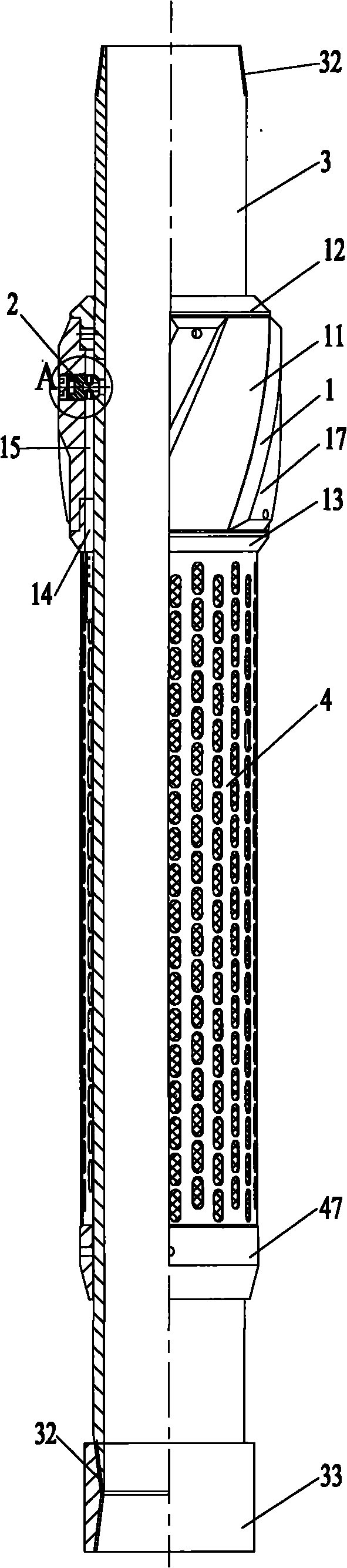

[0024] refer to figure 1 , which is a partially cut-away schematic view of the radially inserted radial flow restrictor of the present invention. from figure 1 As can be seen in the figure, the restrictor 1 includes a restrictor body 11, a first restrictor supporting plate 12, and a second restrictor supporting plate 13, wherein the second restrictor supporting plate 13 is provided with an overflow Groove 14, a restrictor annular space 15 is formed in the restrictor body 11, and the restrictor annular space 15 is conducted with the flow groove 14 of the second restrictor support plate 13, and the restrictor body 11 There are a plurality of flow fitting assembly holes 16 opened thereon.

[0025] In addition, in order that the restrictor 1 can be used as a spiral centralizer, the restrictor body 11 provided by the present invention is provided with spiral ribs 17 .

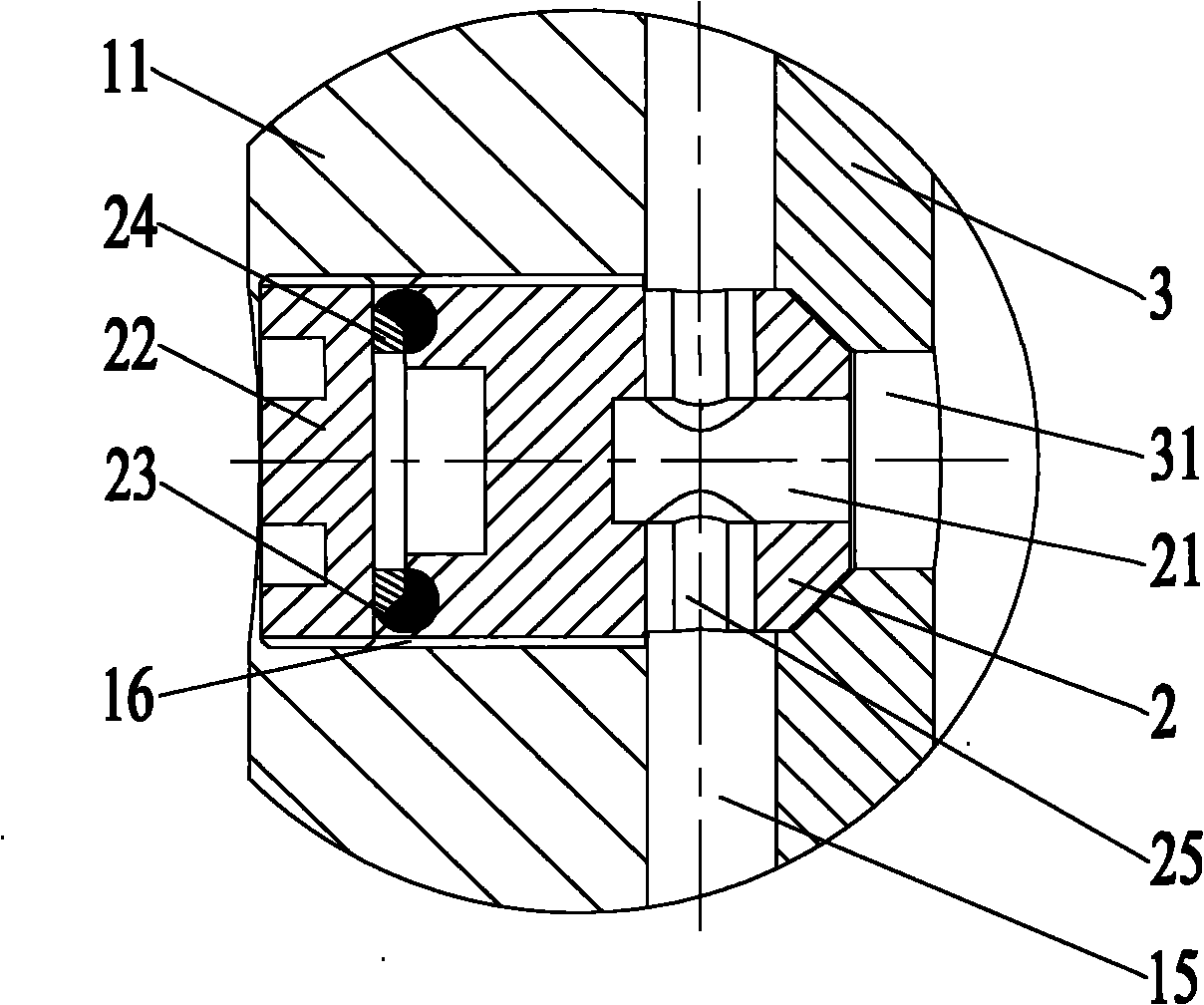

[0026] combine figure 2 , the flow fitting holes 16 are respectively corresponding to the first flow holes 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com