Emptying valve for pipeline of solar energy water heater

A technology for solar water heaters and venting valves, applied in solar thermal power generation, solar thermal devices, heating devices, etc., can solve the problems of easy burnout of venting valve coils, high material costs, and unsatisfactory effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

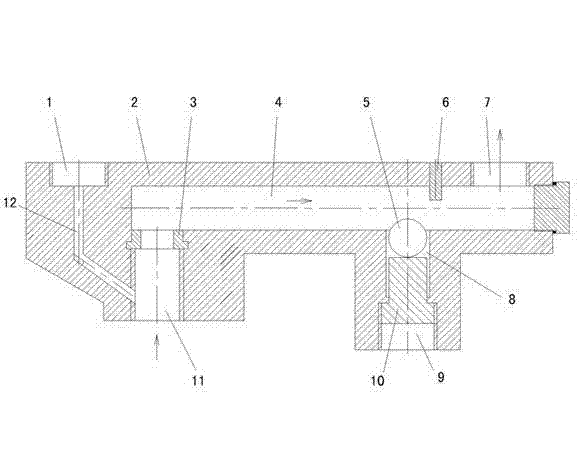

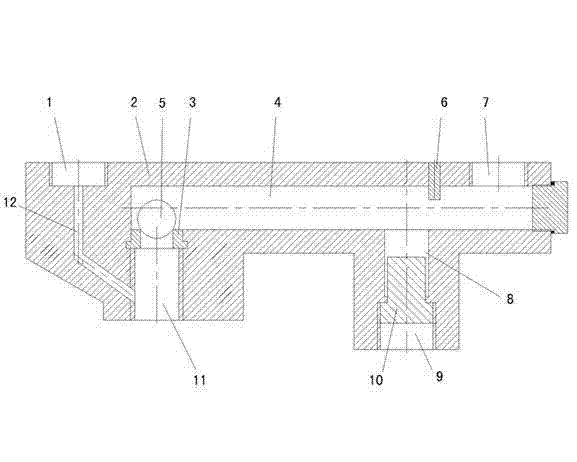

[0010] Such as figure 1 , 2 As shown: 2 is a valve body, a channel 4 is processed in the valve body, and a first water inlet and outlet 11 communicating with the channel 4 is processed on the valve body 2 at one end of the channel 4 .

[0011] On the valve body 2 at the other end of the passage 4, a second water inlet and outlet 7 communicating with the passage 4 is processed in an upward direction.

[0012] The above-mentioned first water inlet and outlet 11 and the second water inlet and outlet 7 are threaded holes, which are convenient for connecting with pipes through pipe joints.

[0013] Between the first water inlet and outlet 11 and the second water inlet and outlet 7 , a ball hole 8 communicating with the channel 4 is processed on the lower side of the valve body 2 , that is, in the downward direction, and the sealing ball 5 is located in the ball hole 8 . There is a wire hole 9 at the outer port of the ball hole 8, and the wire hole 9 is threadedly connected with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com