Automatic return device used in triaxial vibrating system

An automatic return and shaft vibration technology, applied in the field of mechanical environmental testing, can solve the problems of reducing the effective displacement, affecting the accuracy of the vibration test results, and distorting the vibration waveform, achieving improved accuracy, strong anti-environmental interference ability, The effect of maintaining the vibration waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

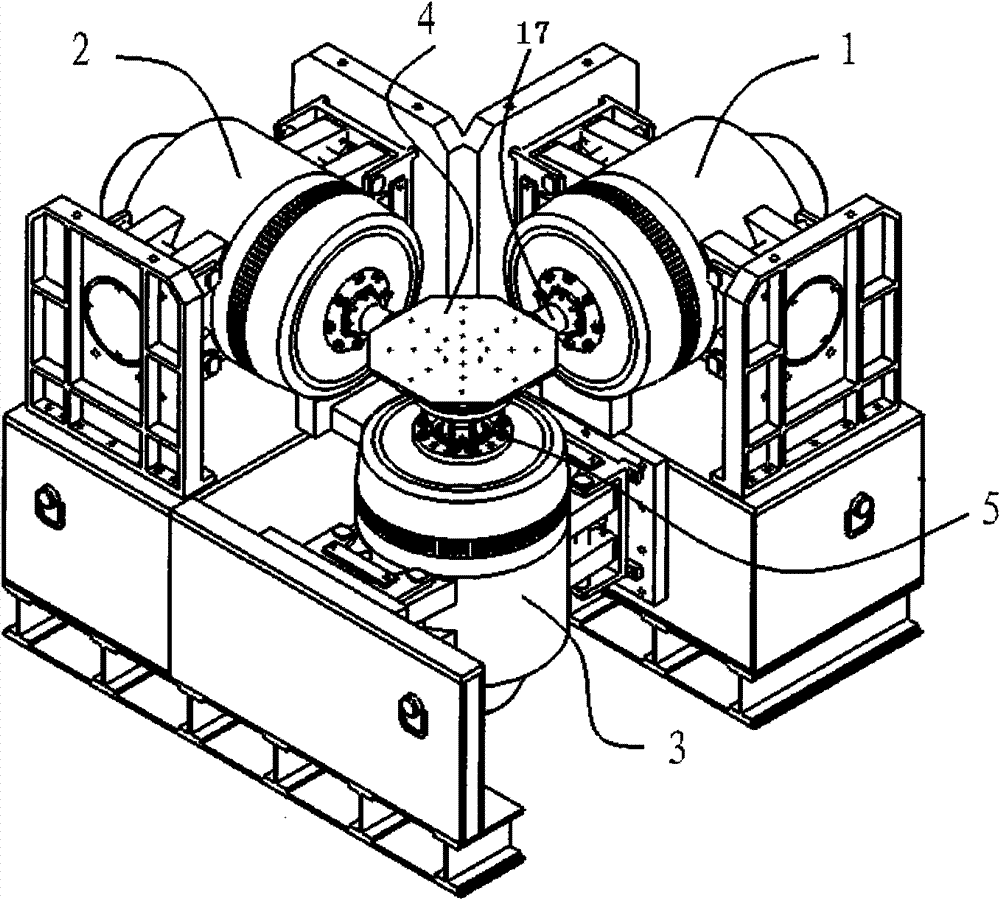

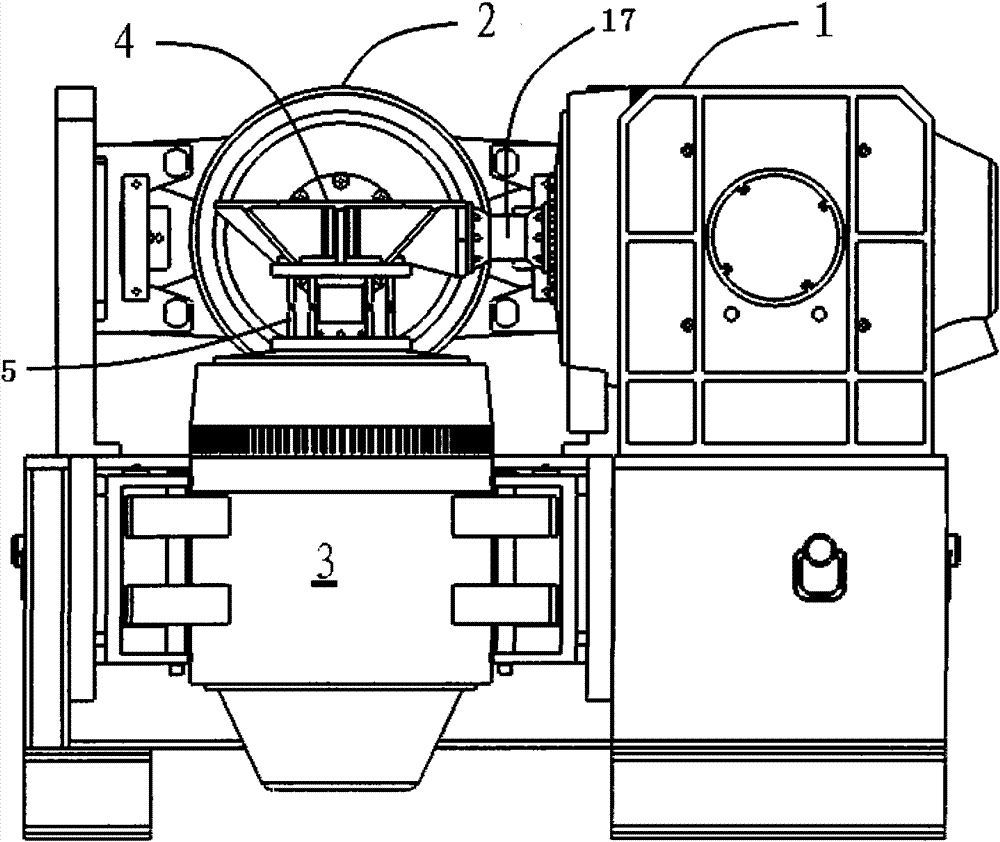

[0018] The automatic return device used in a three-axis vibration system according to the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

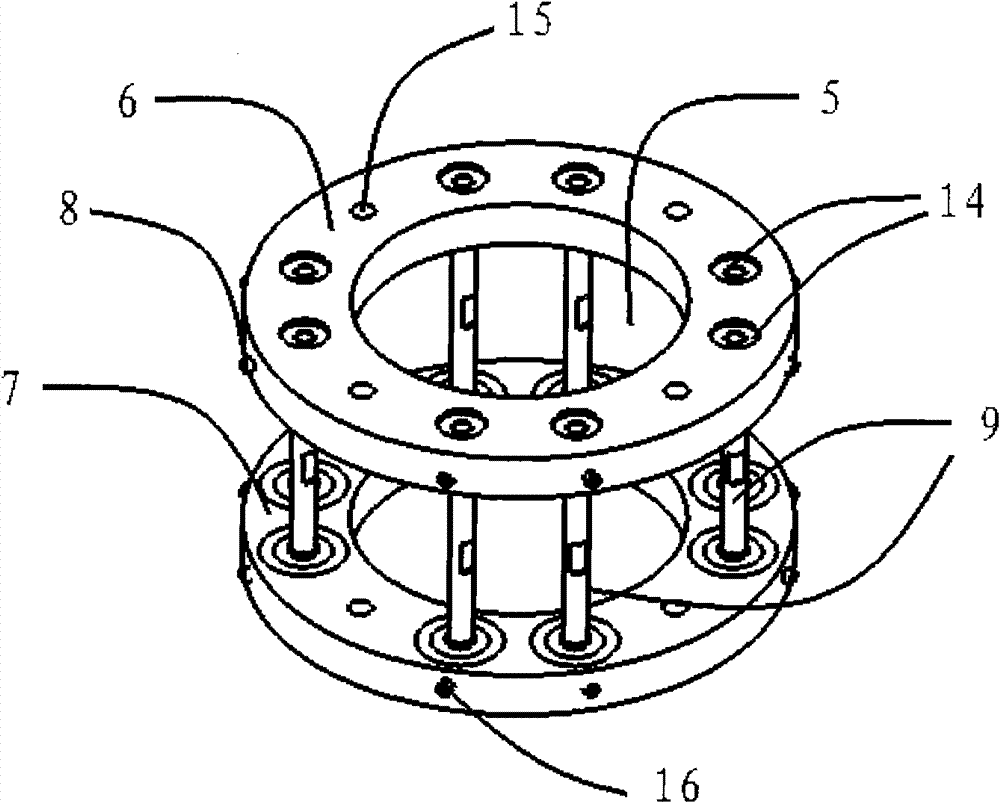

[0019] Such as image 3 Shown: an automatic return device used in a three-axis vibration system, which mainly includes an upper mounting flange 6, a lower mounting flange 7 and an elastic return device 9; the surface of the upper mounting flange 6 There are mounting holes 14 on the symmetrical position of the upper center, and there are 2 mounting holes 14 on the upper, lower, left, and right sides. There are 8 mounting holes 14 in total, and connecting holes 15 are evenly opened on the positions spaced apart from each other, and there are 4 in total. Connecting holes 15; one fixing hole 16 is opened at the corresponding position on the outside of the plate wall of the eight mounting holes 14; the lower mounting flange 7 has the same structure as the upper mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com