Non-contact conductive gas/liquid two-phase flow pattern identifying device and method

A non-contact conductivity, gas-liquid two-phase flow technology, applied in the field of multiphase flow measurement, can solve the problems of reduced conductivity measurement performance, easy to be polarized, electrochemical corrosion, etc., to improve reliability and robustness, easy to use. Implementation, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention proposes a non-contact electrical conduction gas-liquid two-phase flow pattern identification device and method aiming at the status quo of the existing contact-type conduction gas-liquid two-phase flow pattern identification method. The conductivity measurement technology adopted is capacitive coupling non-contact conductivity measurement technology, which can effectively avoid electrode polarization and electrochemical corrosion effects, improve the performance of conductivity measurement, and improve the reliability and reliability of the gas-liquid two-phase flow pattern identification system. Robust, and has the advantages of non-contact, simple structure, easy installation, and low cost.

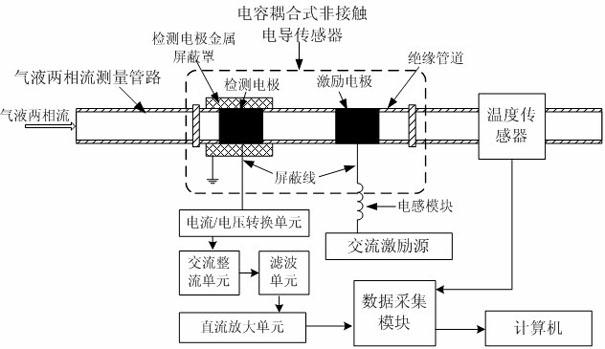

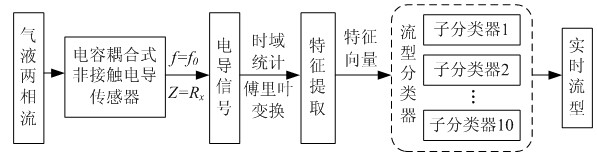

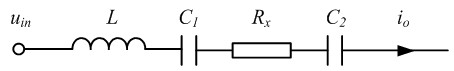

[0026] Such as figure 1 As shown, the non-contact conductivity gas-liquid two-phase flow identification device includes a gas-liquid two-phase flow measurement pipeline, an AC excitation source, a capacitively coupled non-contact conductivity sensor, a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com