Motor

A motor and shaft tube technology is applied in the field of motors that can prevent the shaft tube from being deformed, and can solve the problem that the stator is prone to excessive pressure on the shaft tube and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

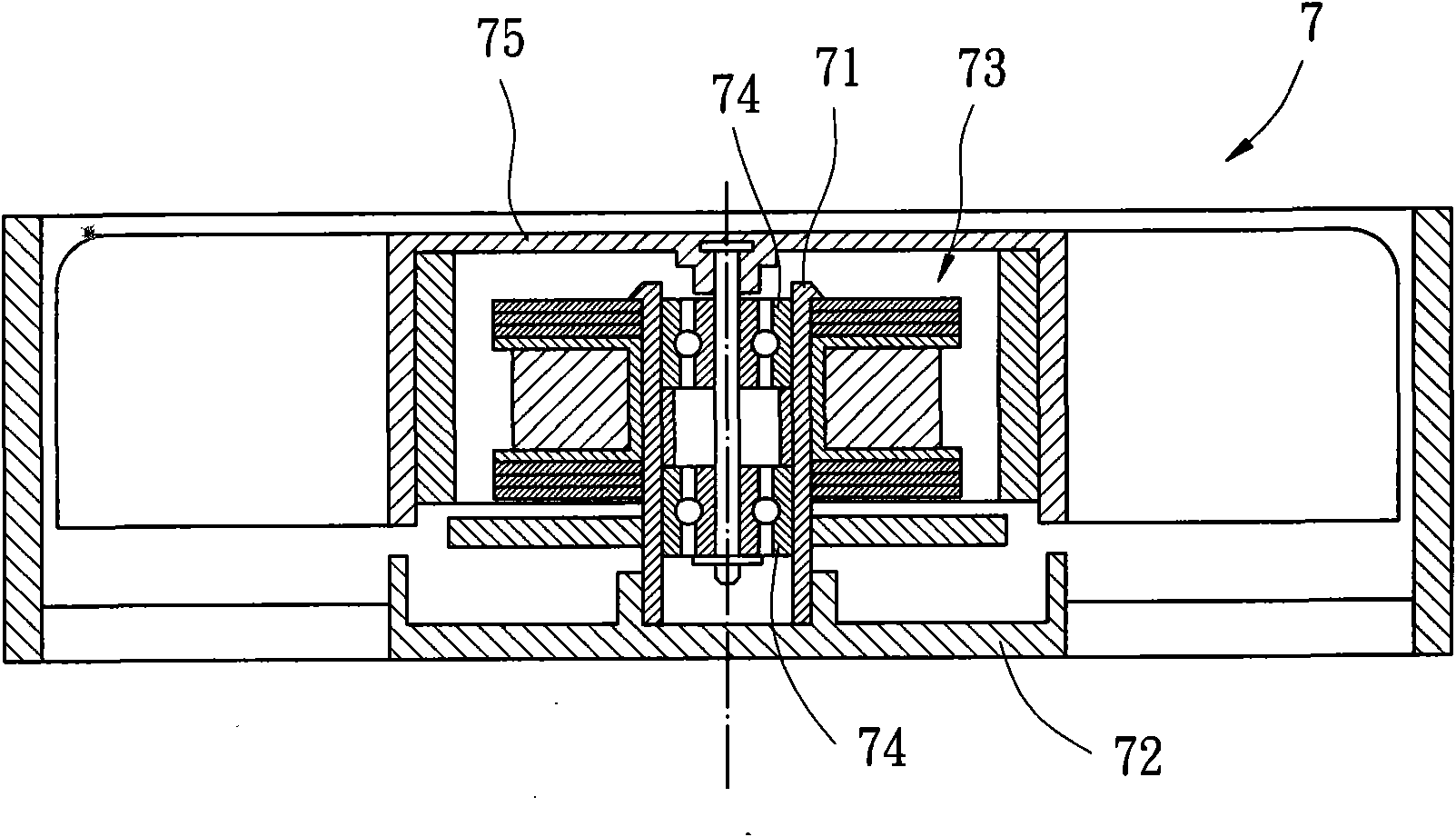

[0051] Please refer to Figure 4 , 5 Shown in and 6 is the first embodiment of the tight fitting portion 4 and the adjustment gap 5 . Wherein the tight fit portion 4 can be at least one protrusion (such as a convex rib, a bump or other structural design with the same function) formed on the inner wall of the assembly hole 21, and the shaft tube 11 has an outer diameter in the radial direction. Tube diameter D, with the help of the design of the at least one protrusion, the minimum diameter of the assembly hole 21 is smaller than the outer tube diameter D of the shaft tube 11, so that the stator group 2 can be more tightly combined with the outer peripheral wall of the shaft tube 11 111; In addition, in this embodiment, the convex part is designed as a convex rib 211, and there are two convex ribs 211 (only one can be selected according to requirements), and the two convex ribs 211 can axially extend to the assembly hole 21 The inner hole wall of the rib 211 abuts against the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com