Mechanical seal

一种机械密封件、侧密封的技术,应用在发动机的密封、机械设备、发动机元件等方向,能够解决安装空间和消耗动力增大、泄漏等问题,达到削减初始成本、防止磨损、缩短密封箱的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

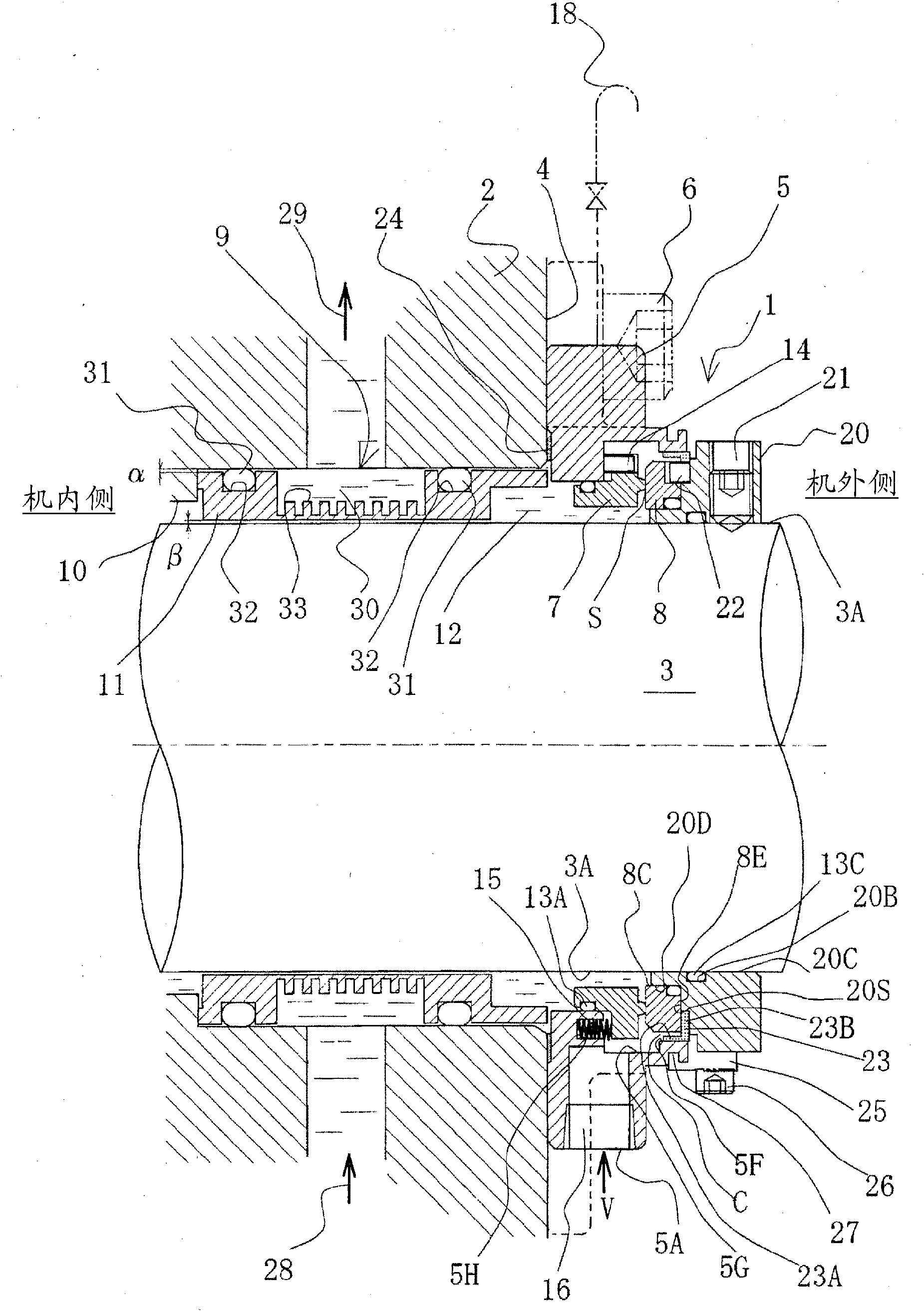

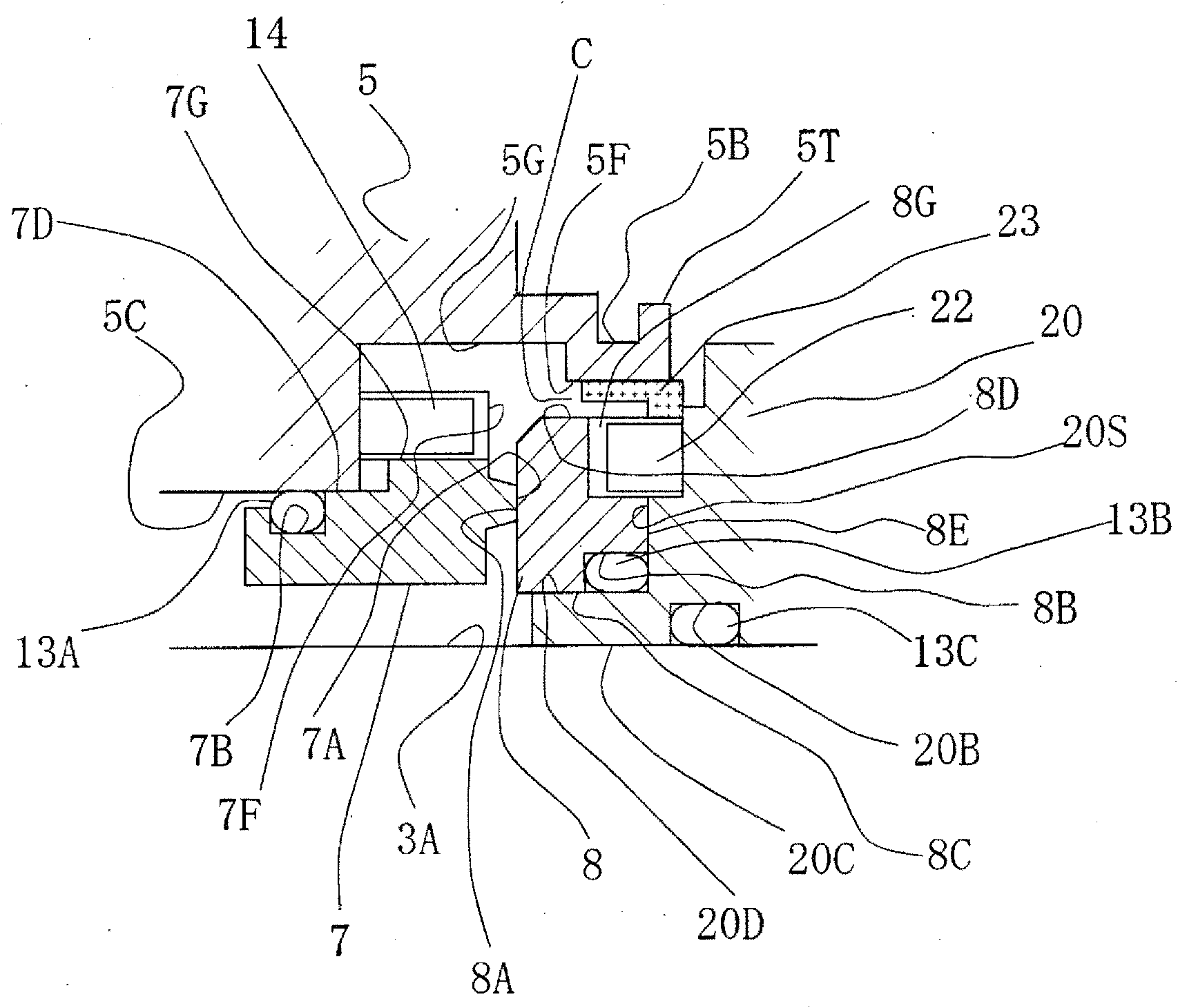

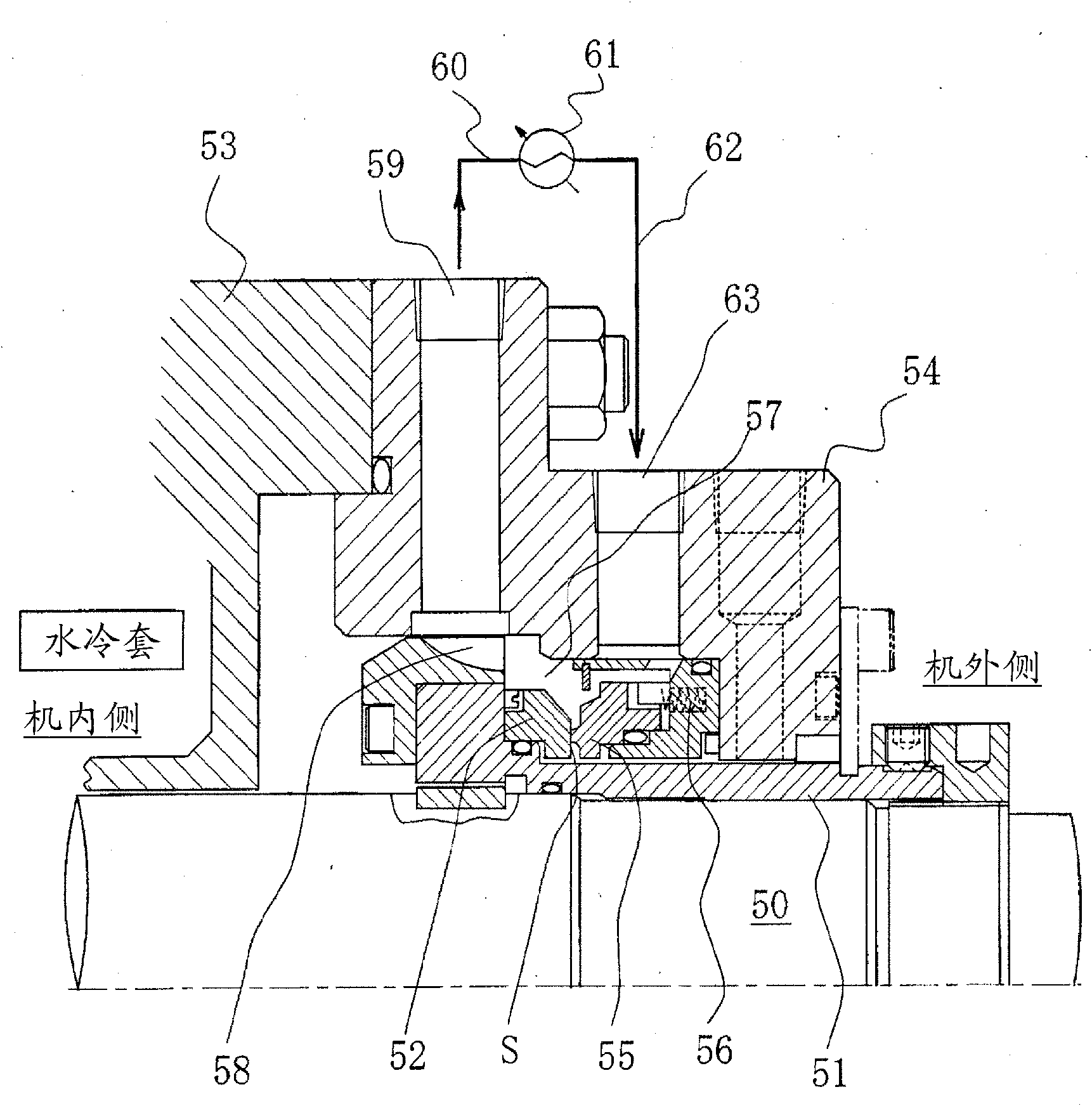

[0037] The mode for implementing the mechanical seal of the present invention will be described in detail with reference to the accompanying drawings, however, the present invention is not construed as being limited thereto, as long as it does not depart from the scope of the present invention, various Change, fix, improve.

[0038] figure 1 It is a front sectional view showing the whole of the mechanical seal according to the embodiment of the present invention, and, figure 2 is zoomed in figure 1 An enlarged view of the main part of the main part.

[0039] The mechanical seal 1 is used for the casing 2 of the shaft seal part of the pump that handles high-temperature liquids exceeding 200°C, such as hot water pumps such as boiler water pumps or condensate pumps in thermal power plants, and hot oil pumps. Sealing is performed between the rotating shaft 3 in the shaft fitting hole 10 of the housing 2, and the mechanical seal 1 is fitted between the housing 2 and the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com