Movable ankle baseboard

A foot plate and ankle foot technology, applied in the field of moving ankle foot plate, can solve the problems of stiffness, discomfort in wearing of amputee patients, easy loosening of the moving ankle foot plate and the shell, etc., to increase strength and flexibility, increase comfort, and increase flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the drawings, so that those skilled in the art can better understand the present invention. It is possible to modify, add and replace the following embodiments without exceeding the protection scope of the present invention.

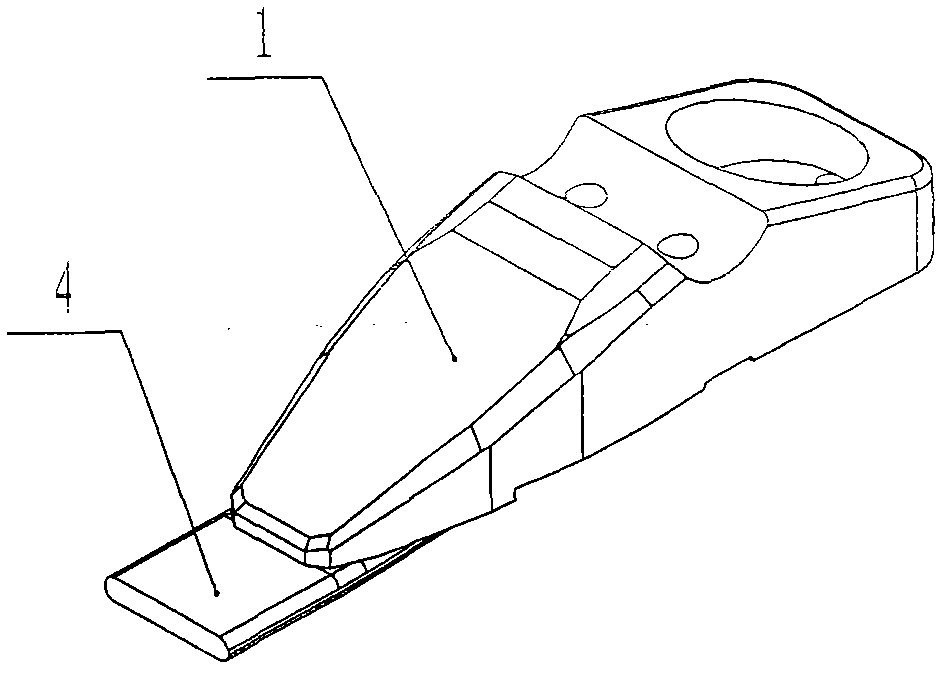

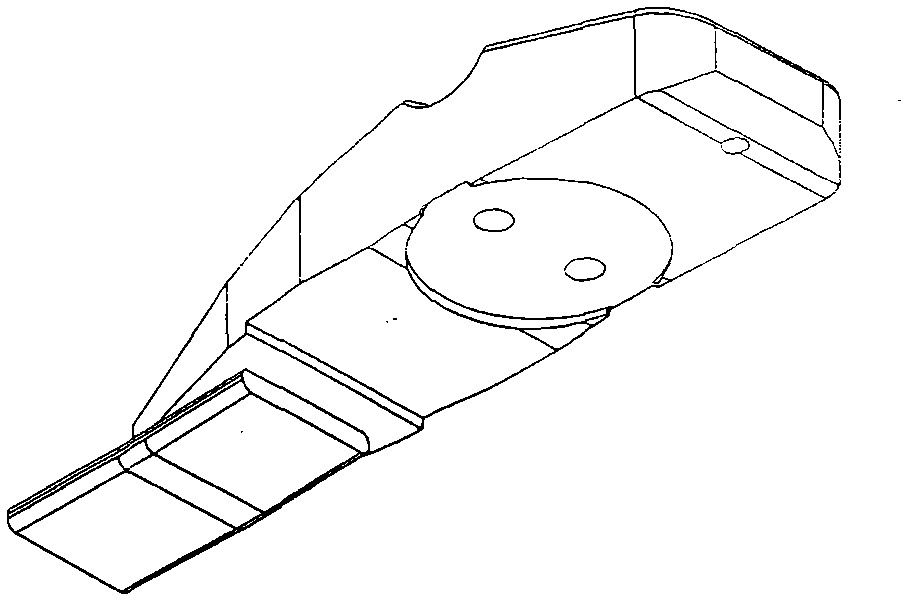

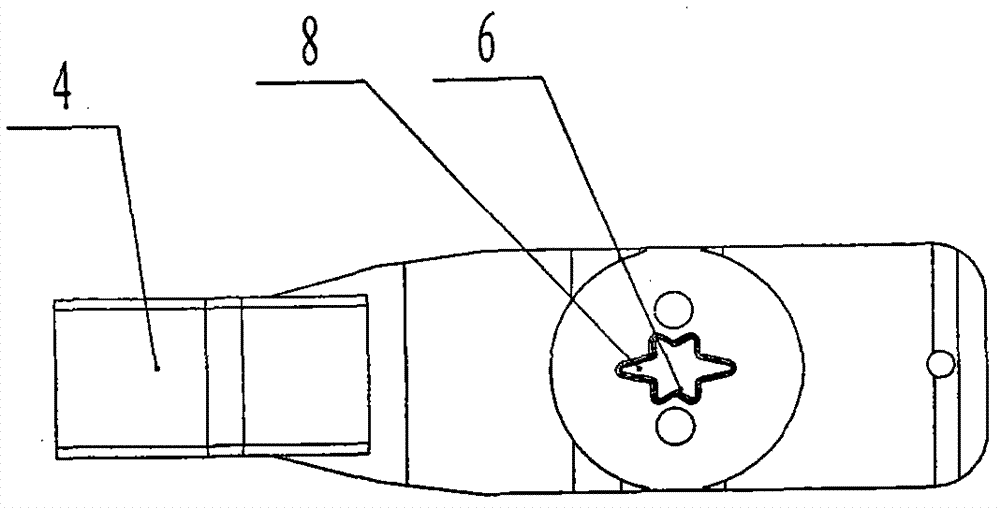

[0023] like image 3 As shown, a movable ankle foot plate is composed of a movable ankle keel 1 and a forefoot shrapnel 4. There is a connecting hole 6 located in the middle of the foot center at the bottom of the movable ankle keel 1, and there are shallow grooves 8 on the front and rear sides of the connecting hole 6. , the depth and width of the connection hole 6 are greater than the shallow groove 8, and the inner angle of the connection hole 6 is an acute angle, which is star-shaped in this example, and can also be radial.

[0024] like Figure 4 , Figure 5 , Image 6 , shown in Fig. 7, Fig. 8, a kind of wooden double-hole movable ankle foot plate is made up of do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com