Film laminating machine

A technology of laminating machine and frame, which is applied in the direction of lamination device, lamination auxiliary operation, winding strip, etc., can solve the problems of high labor intensity, poor work efficiency, poor film tension control accuracy, etc., and improve work Efficiency, improved product quality, and quick roll change effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

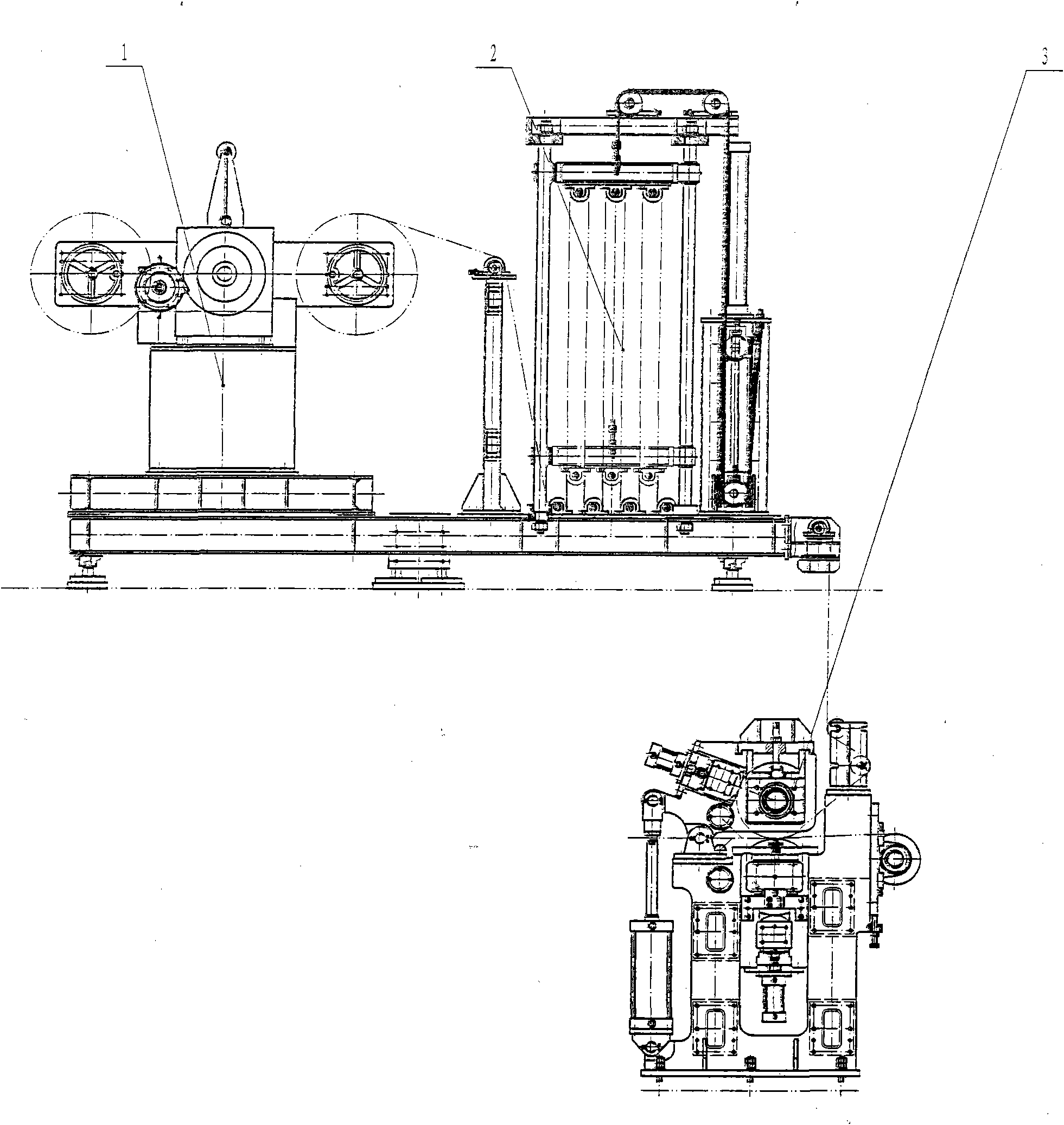

[0012] like picture One shows: This equipment mainly has three parts, which are uncoiler 1, looper 2, and pressing machine 3; uncoiler 1 is fixed on the base of the looper, the looper is installed on the platform, and the pressing machine is installed on the foundation. The metal strips are coated with adhesive by a roller coater before entering the laminator, and then enter the drying furnace to completely volatilize the volatile components of the adhesive, and enter the laminator at a certain temperature.

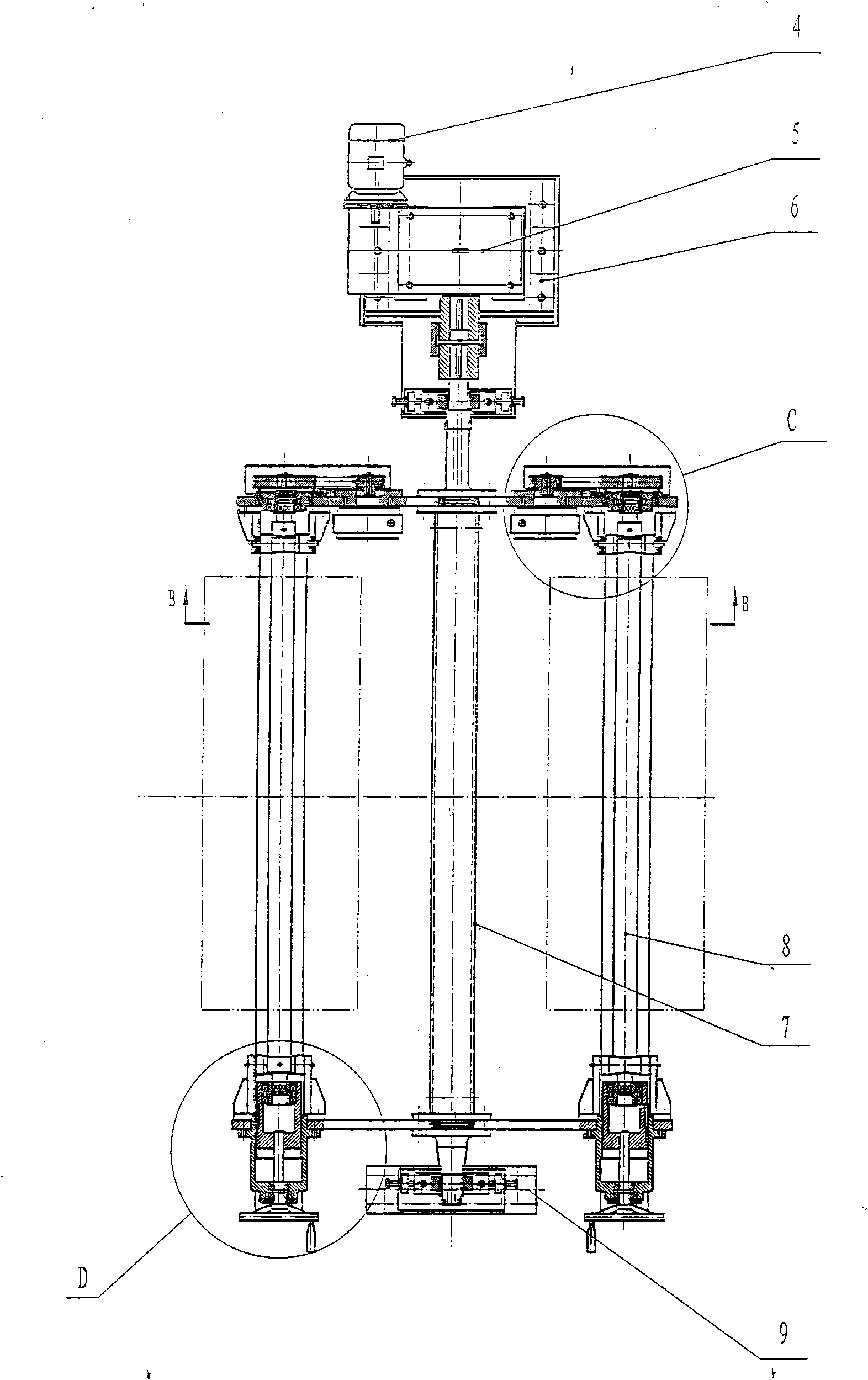

[0013] The function of the uncoiler is to supply the film for the lamination, such as picture As shown in two, the structure is mainly composed of a transmission side base 9, an operation side base 6, a rotating roll changing arm 7, an air expansion shaft 8, a speed reducer 5, and a motor 4. The base on the transmission side and the base on the operating side are installed on the looper base. The rotating roll changing arm is installed on the base on the transmission sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com