Elastic unit combined tire

An elastic unit and combined technology, applied in directions with multiple inflatable chambers, segmented casings, etc., can solve problems such as heavy load, carcass is not resistant to puncture and cutting, and tread is easy to wear, so as to save equipment The effect of investing, alleviating carcass subsidence, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

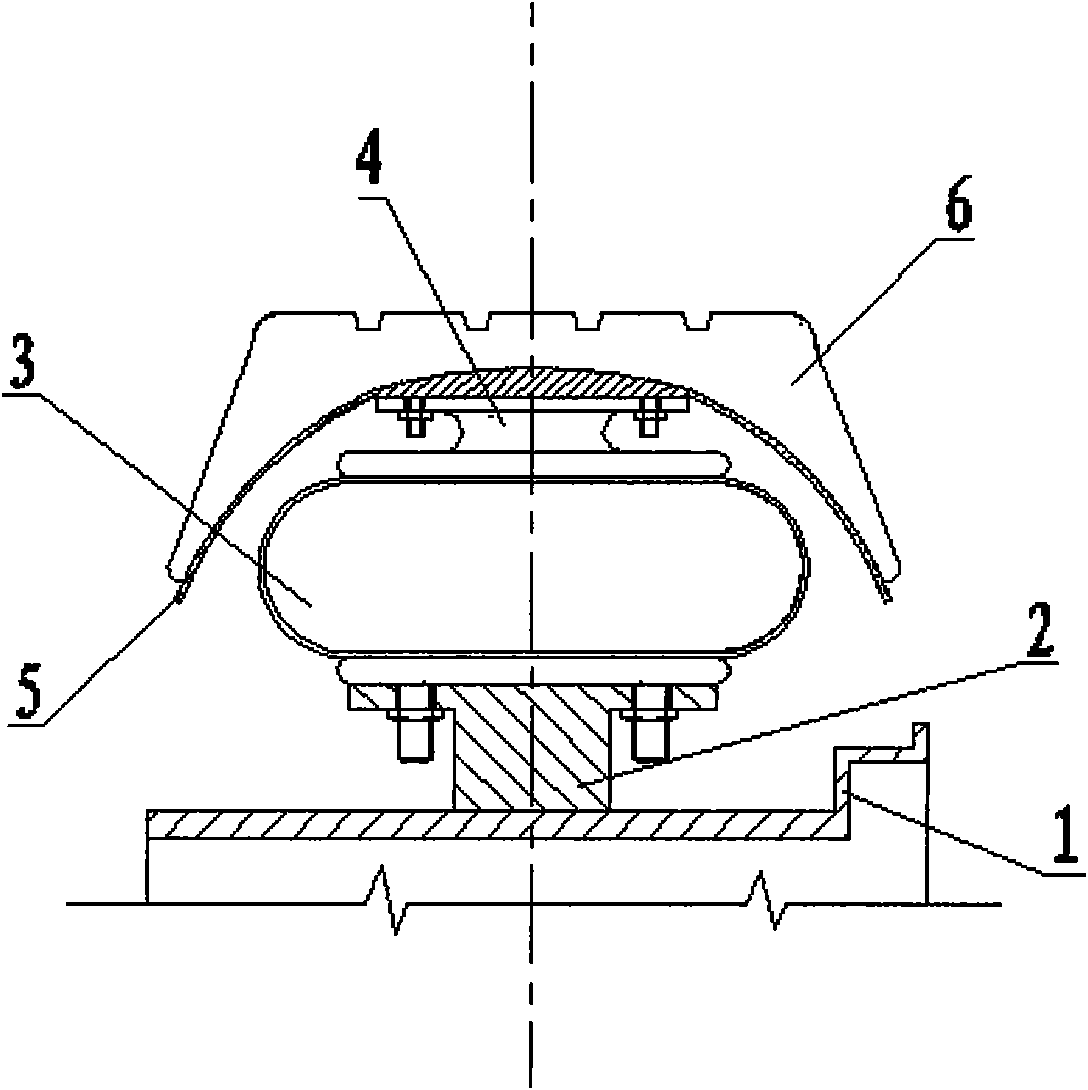

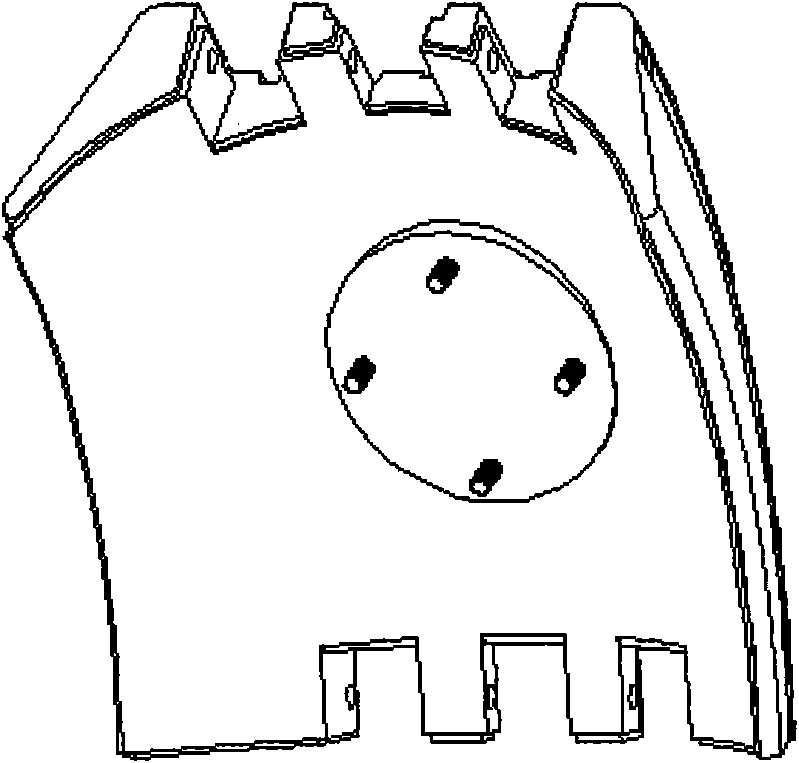

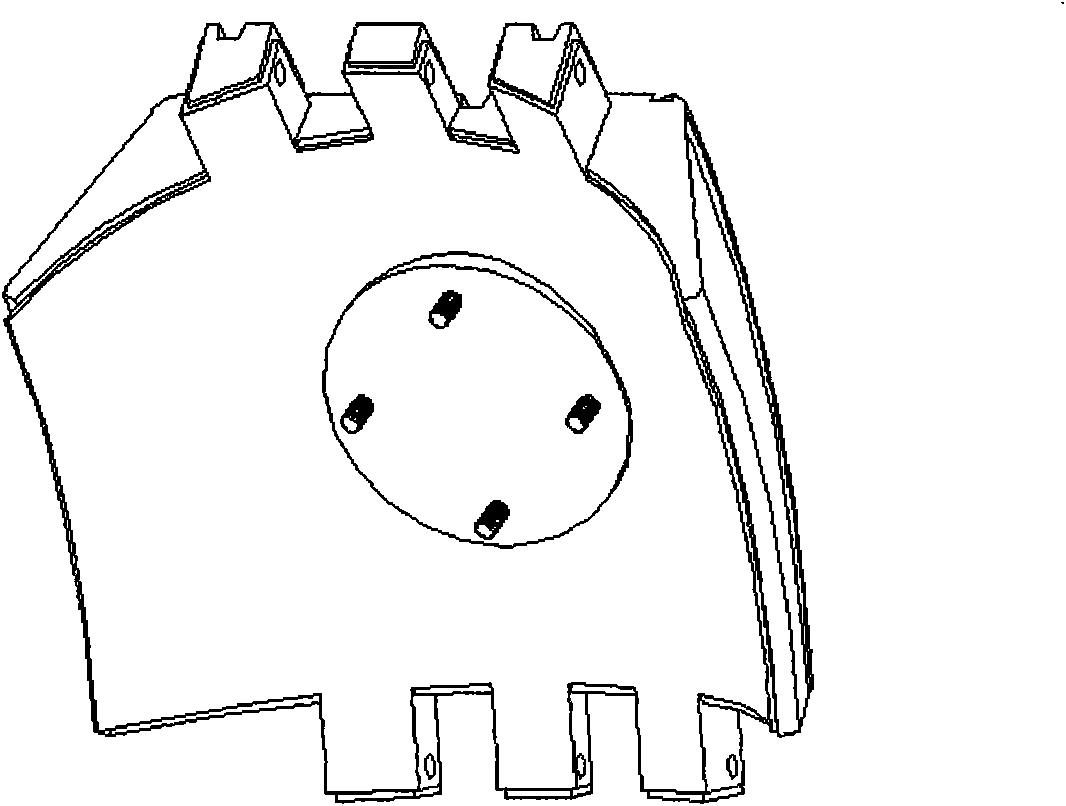

[0014] An elastic unit combined tire of the present invention is mainly composed of a rim 1, a rubber air spring 3, a metal shell 5, and a tread rubber 6, such as figure 1 As shown, there are a certain number of rim bosses 2 arranged at equal intervals along the centerline of the circumference of the rim 1, and the rubber air spring 3 is fixed on the rim 1 through the rim boss 2, and the upper part of the upper end plate of each air spring 3 is also There is a boss 4 with a screw hole on it, and the metal shell 5 is fixedly assembled with the rubber air spring 3 through the boss 4. The surface of each metal shell 5 is covered with a section of tread rubber 6, and the two adjacent metal shells The ends of body 5 are connected by hinge 7, the connection structure is shown in figure 2 and 3 shown. In this way, each rubber air spring 3, the metal shell 5 and the tread rubber 6 covered on the surface of the shell form an elastic unit, and a certain number of elastic units form a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com