Single-upright telescopic carriage

A single-column and carriage technology, applied in the field of conveying machinery, can solve problems such as low work efficiency, large space occupation, and complex overall structure of double-column carriages, and achieve the effects of space saving, safe and reliable work, and compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with specific drawings and embodiments.

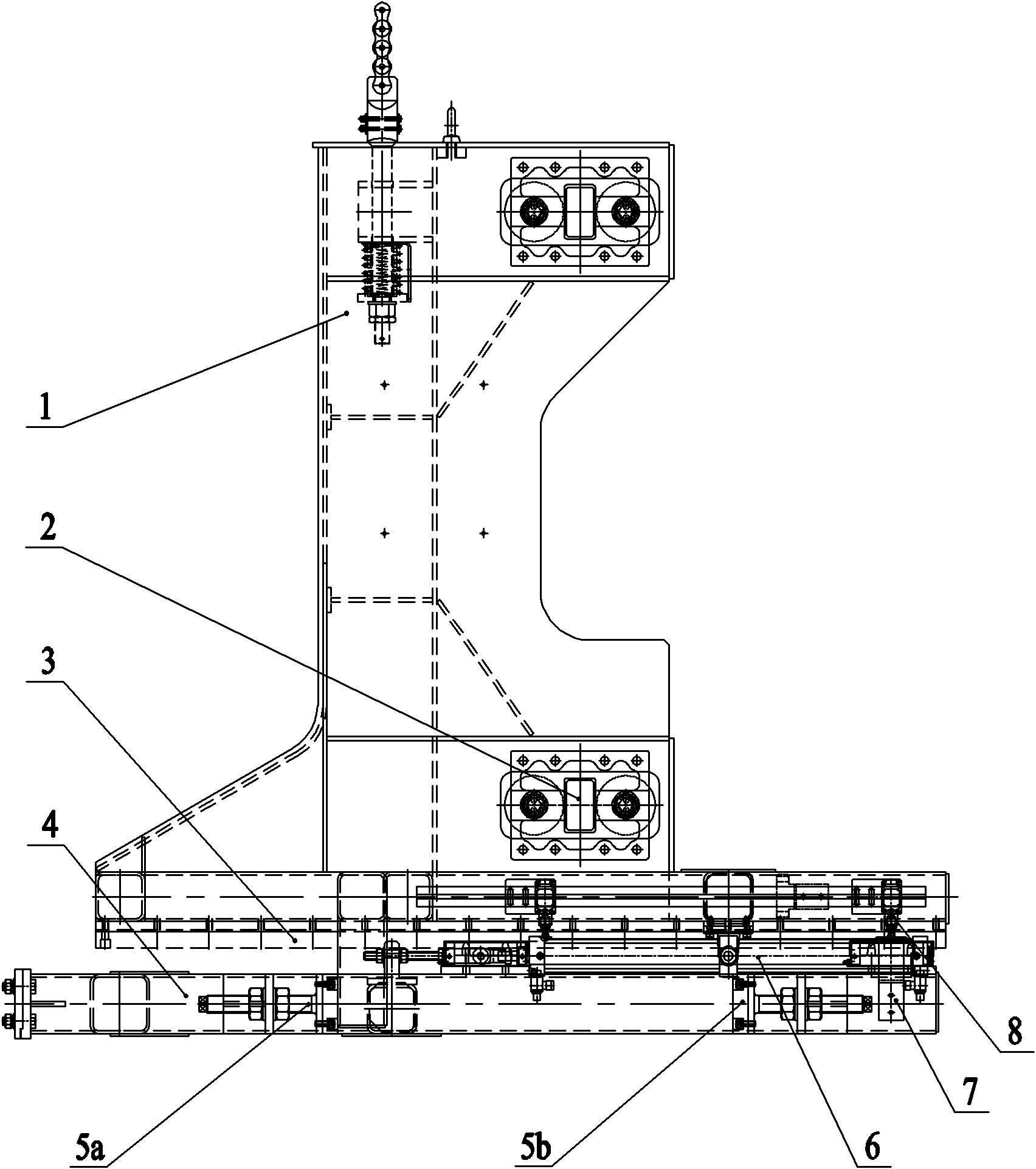

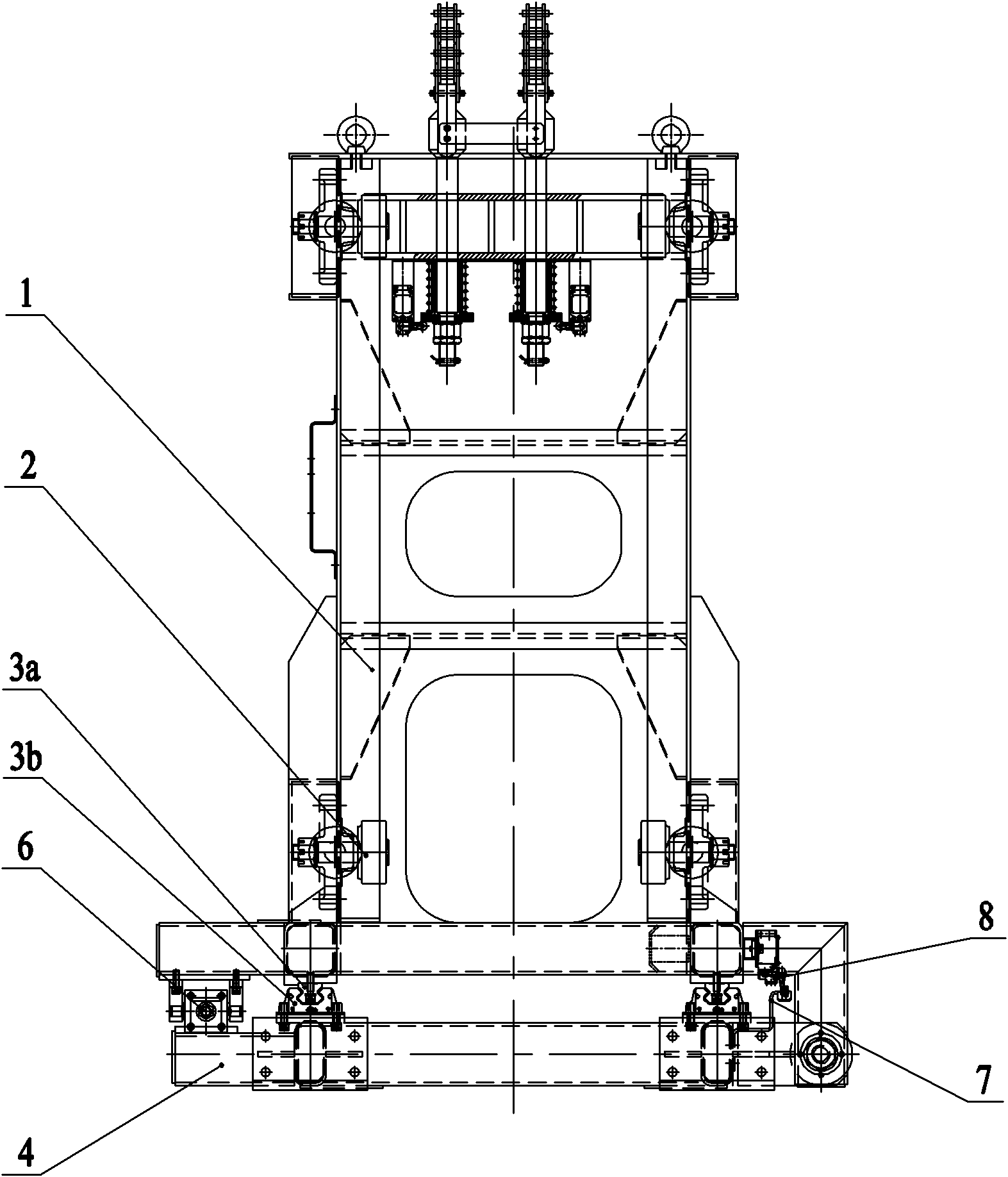

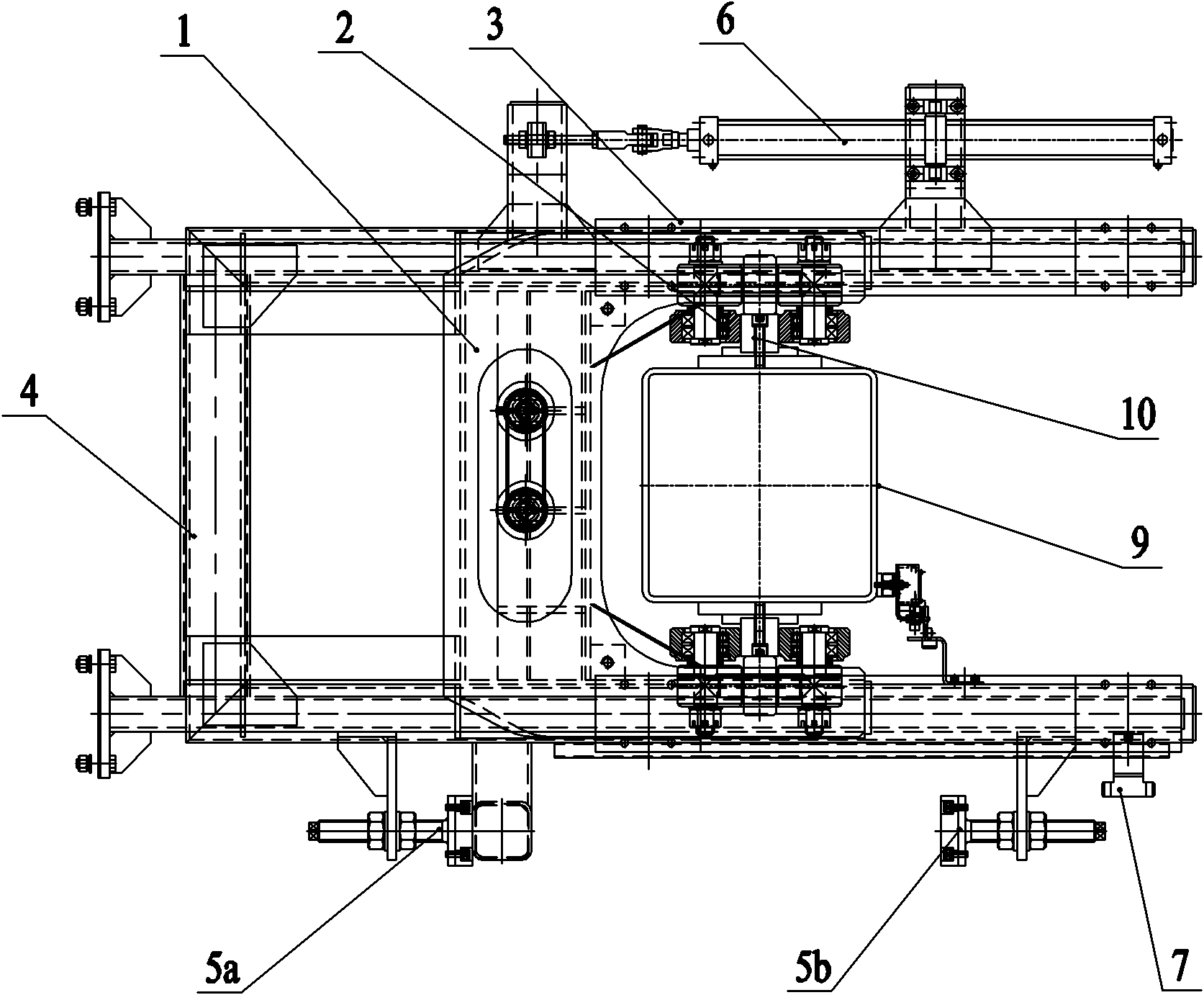

[0016] As shown in the figure: the single column telescopic carriage in the embodiment is mainly composed of a column 9 and a carriage mechanism, the column 9 has only one, the carriage mechanism is U-shaped, and the carriage mechanism encloses the column 9; The inner sides of both sides of the carriage mechanism are respectively provided with guide wheel assemblies 2, and the vertical guide rails 10 corresponding to the guide wheel assemblies 2 on both sides of the carriage mechanism are provided on the column 9, and the carriage mechanism passes the guide wheel assemblies 2 on the column. 9Swipe up and down. The guide wheel assembly 2 is composed of three guide wheels, and the three guide wheels are rollingly supported on three sides of the vertical guide rail 10 respectively.

[0017] like Figure 1~Figure 3 As shown, the carriage mechanism is mainly compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com