Yarn-passing alarm panel for embroidery machine

An embroidery machine and thread passing technology, which is applied in the field of thread passing alarm panels of embroidery machines, can solve problems such as troublesome tension adjustment, heavy threading workload, and false alarms, and achieve the effects of convenient and effective tension, shortened threading time, and smooth rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

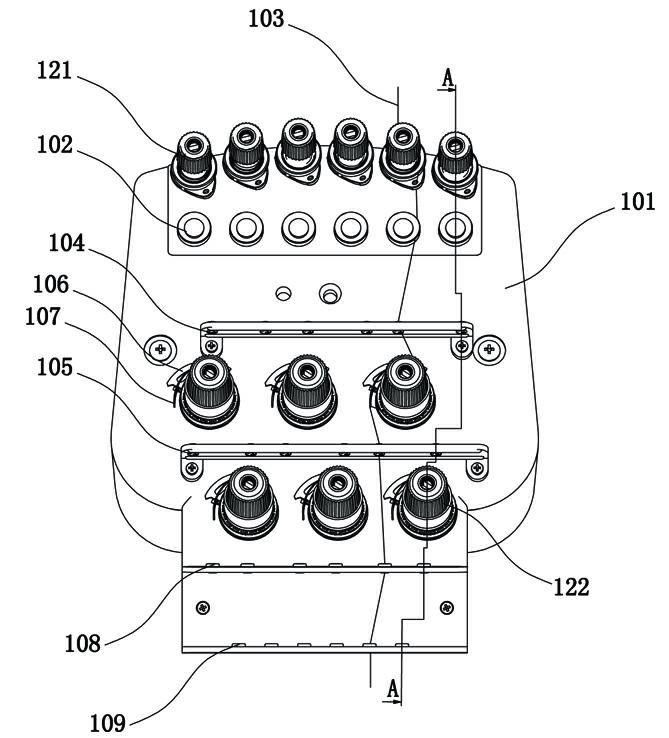

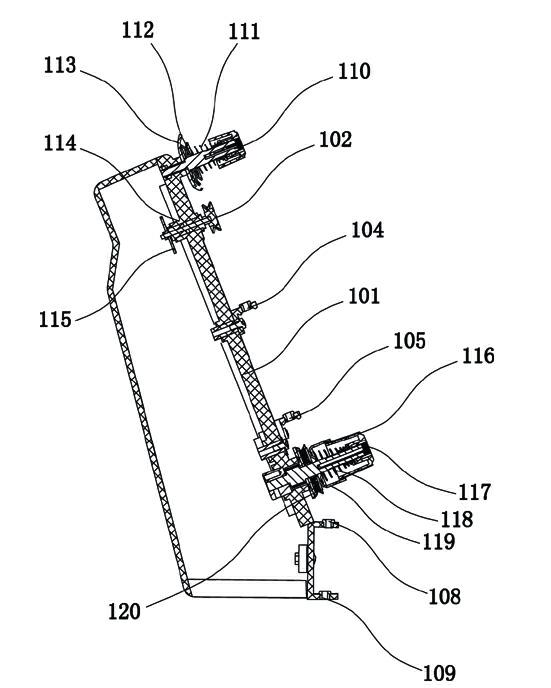

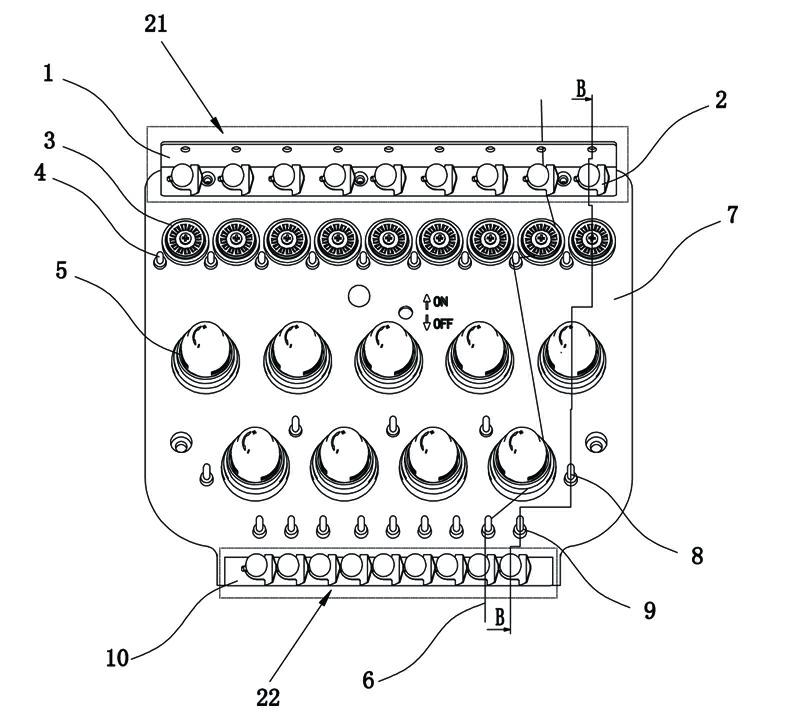

[0024] Embodiment 1: as figure 1 As shown, a thread-passing alarm panel of an embroidery machine includes a base plate 7 on which a thread gripper, a thread-passing detector, an upper thread tension regulator 23 and thread-passing nails 4, 8, 9 are arranged. The thread tensioner includes an upper thread tensioner 21 and a lower thread tensioner 22. The upper thread tensioner 21 and the lower thread tensioner 22 are respectively arranged at the upper and lower ends of the substrate 7; the lower side of the upper thread tensioner 21 is provided with a thread passing detection The upper side of the lower thread clamp 22 is provided with a surface tension regulator 23, and the thread passing detector is located on the upper side of the surface tension regulator 23.

[0025] Such as figure 2 As shown, the wire passing detector includes a wire passing wheel 3, a ball bearing 12, a shaft pin 13 and a light blocking sheet 14, the ball bearing 12 is embedded and installed on the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com