System and method for cooling motor with liquid

A liquid cooling and liquid technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of easy failure, heat removal, inability to fully cool or even lubricate the bearing, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

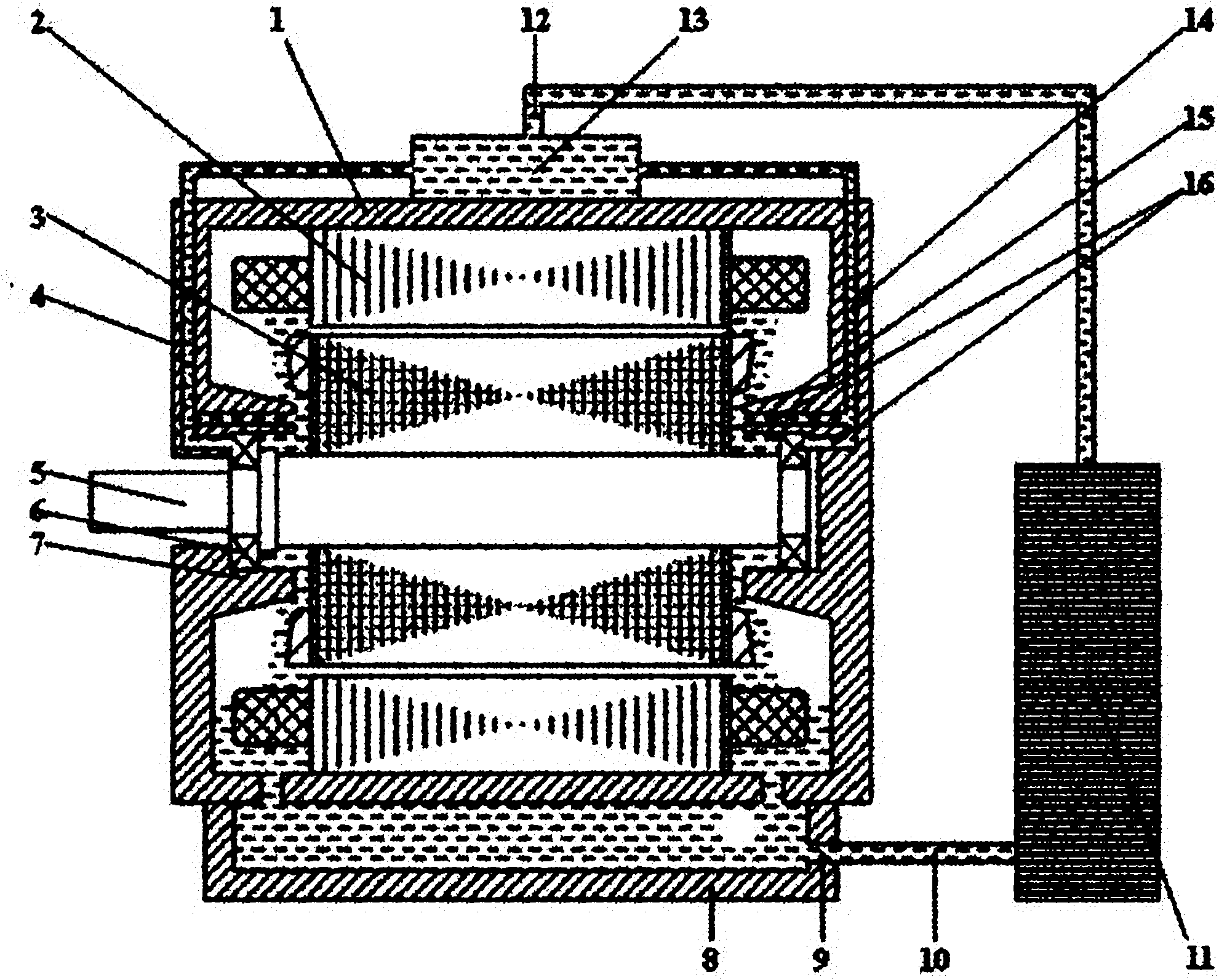

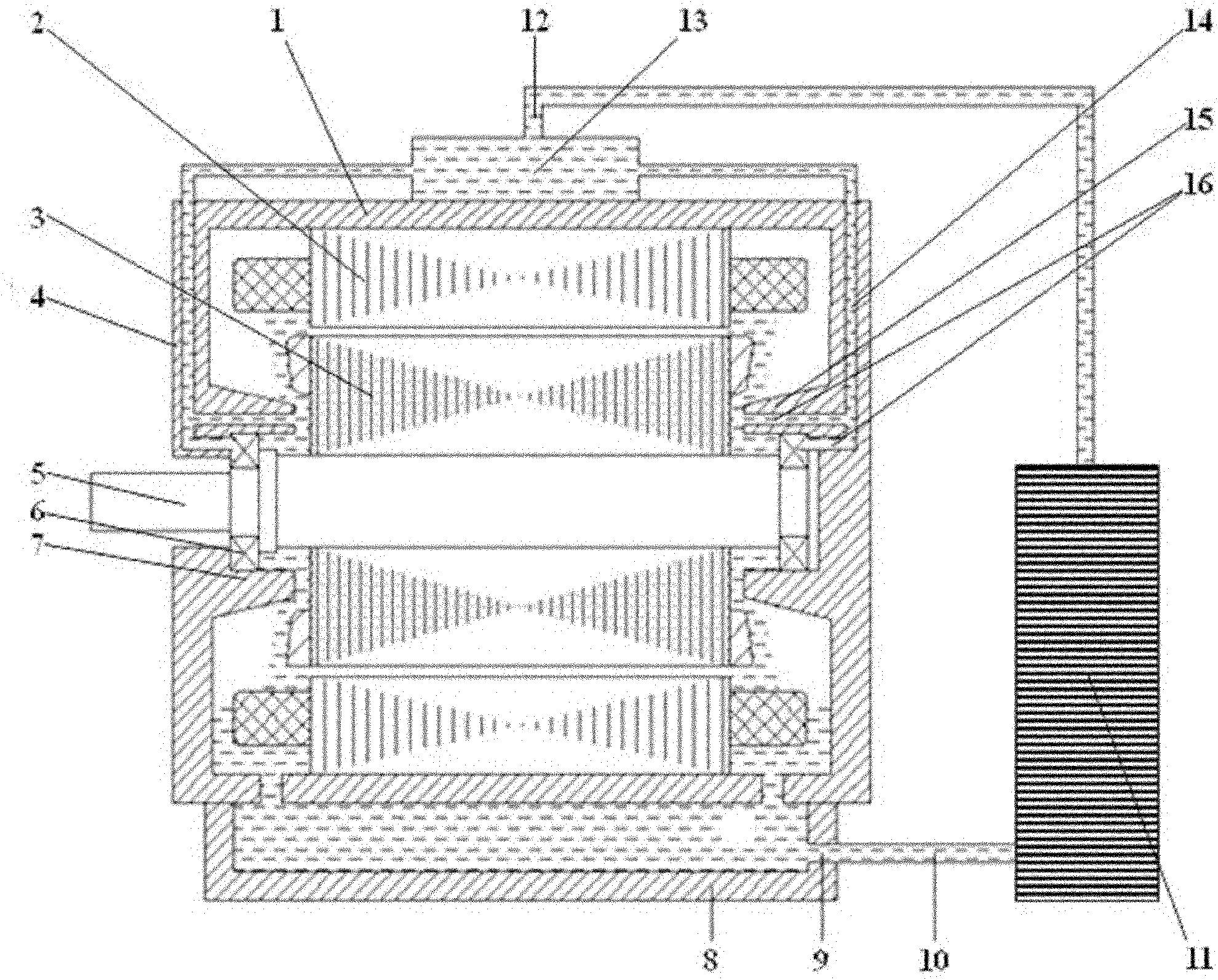

[0023] Below in conjunction with accompanying drawing, the specific embodiment of the invention is described in further detail:

[0024] figure 1 , is a typical specific implementation, and the housing 1, stator 2, rotor 3, end cover 4, shaft 5, bearing 6, and bearing chamber 7 basically constitute a motor system.

[0025] The liquid storage tank 8, the liquid outlet 9, the liquid pipeline 10, the liquid external circulation device 11, the liquid inlet 12, and the liquid distribution box 13 basically constitute a liquid external circulation system.

[0026] The wall of the bearing chamber 7 is provided with an injection port 16, and the liquid ejected from the injection port 16 flows through the vicinity of the bearing 5 or its balls, and after cooling the bearing 6, it jets to the shaft 5 superior.

[0027] A protrusion 15 is also provided, and the protrusion 15 is connected to the inner end surface of the side wall of the bearing chamber 7 .

[0028] The injection port 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com