Fully automatic step bean curd compression molding machine

A step-by-step, fully automatic technology, applied in the field of food machinery, can solve the problems of inadequate control and poor connection of production processes, and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

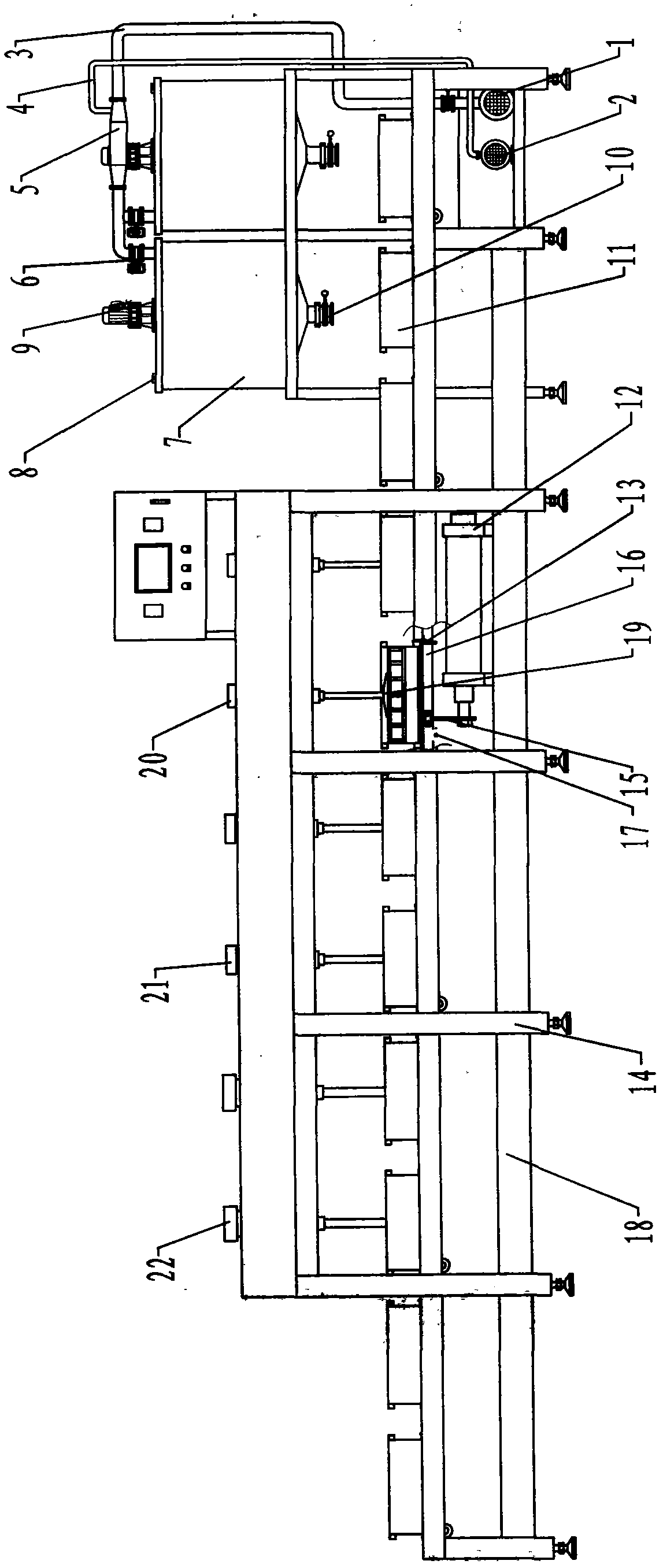

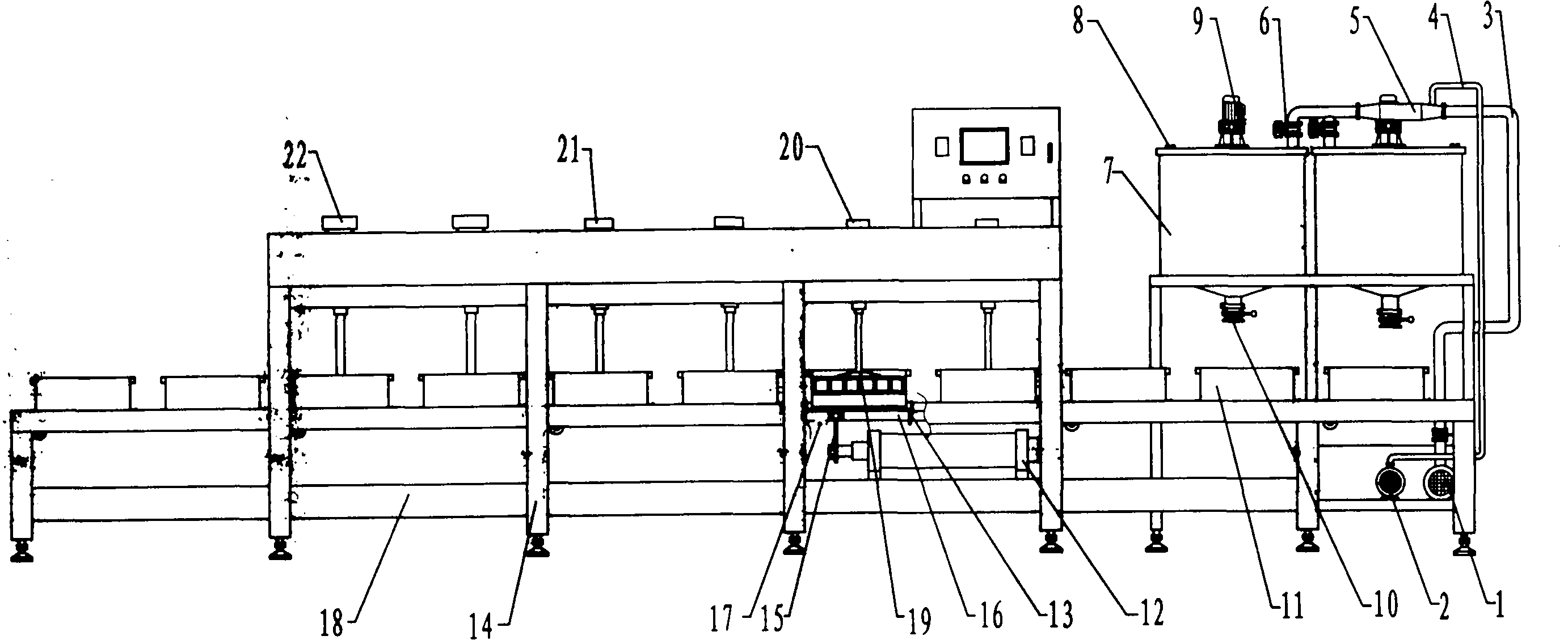

[0009] A fully automatic stepping type tofu pressing and forming machine, including a PLC and a production line frame 14. Above the production line frame 14, a bit of bitter device and a pressing device are sequentially arranged from right to left. Slurry pump 1 and brine pump 2, slurry pump 1 is connected with mixer 5 through slurry pipe 3, brine pump 2 is connected with mixer 5 through brine pipe 4, mixer 5 is connected to the brine cylinder through electrically controlled pneumatic valve 6 7 is connected, and the mixing and fluttering device 9 and the liquid level controller 8 are arranged on the bittern tube 7, the brain valve 10 is provided at the bottom of the bitter tube 7, and the production line below the brain valve 10 is correspondingly provided with tofu Frame 11; the pressing device includes a first group of pressing devices 20, a second group of pressing devices 21, and a third group of pressing devices 22 that are electrically connected to the PLC. The pressing pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap