Integral brake control mechanism for operating bed

A brake control, operating bed technology, applied in the field of parking brakes, to achieve the effect of eliminating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

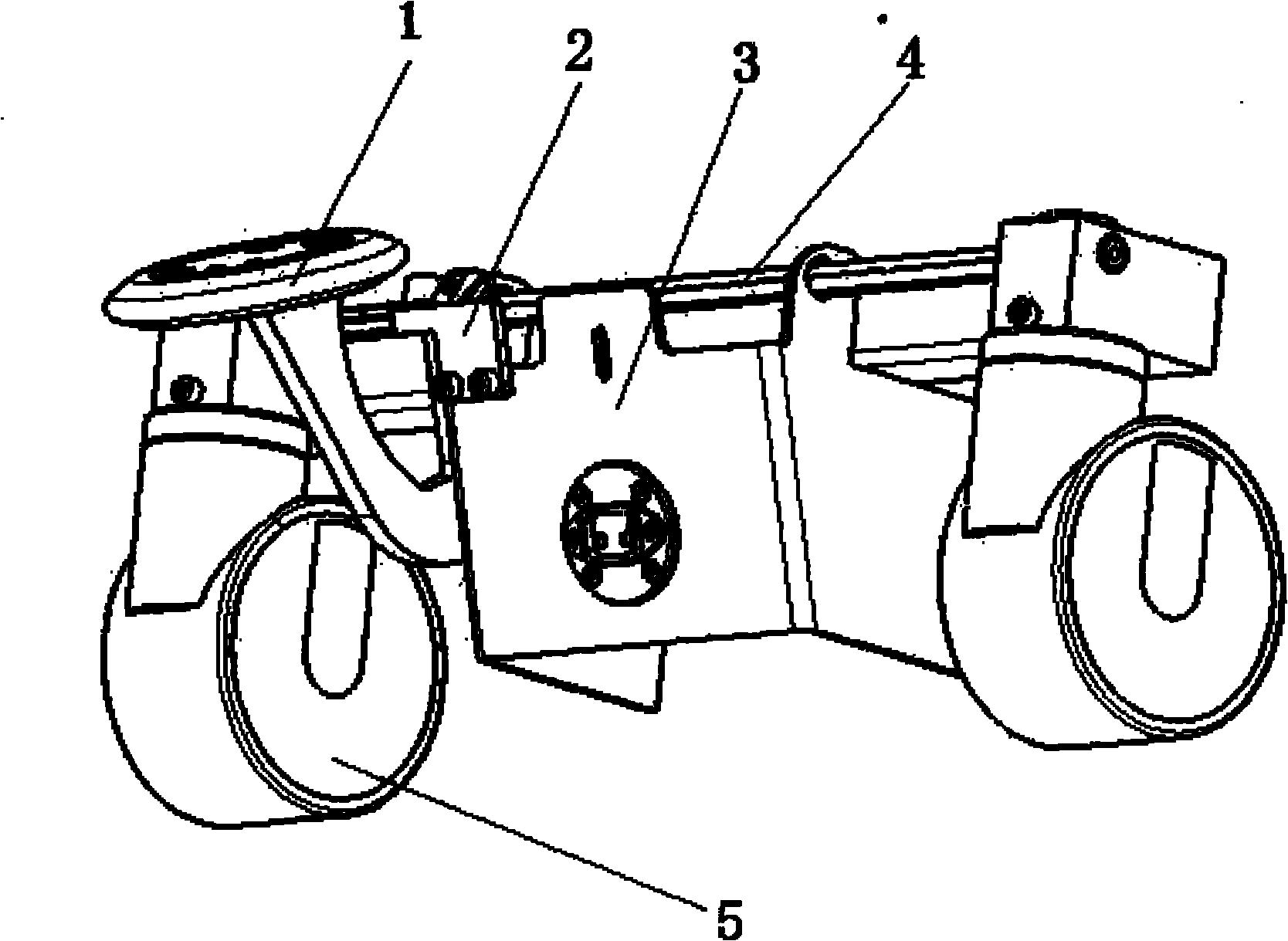

[0013] Such as figure 1 The overall braking control mechanism for an operating bed includes a bracket 3, a universal wheel 5 is installed on both sides of the bracket 3, a connecting rod 4 is arranged between the two universal wheels 5, and a connecting rod 4 is installed on the connecting rod 4. There is pedal assembly 1.

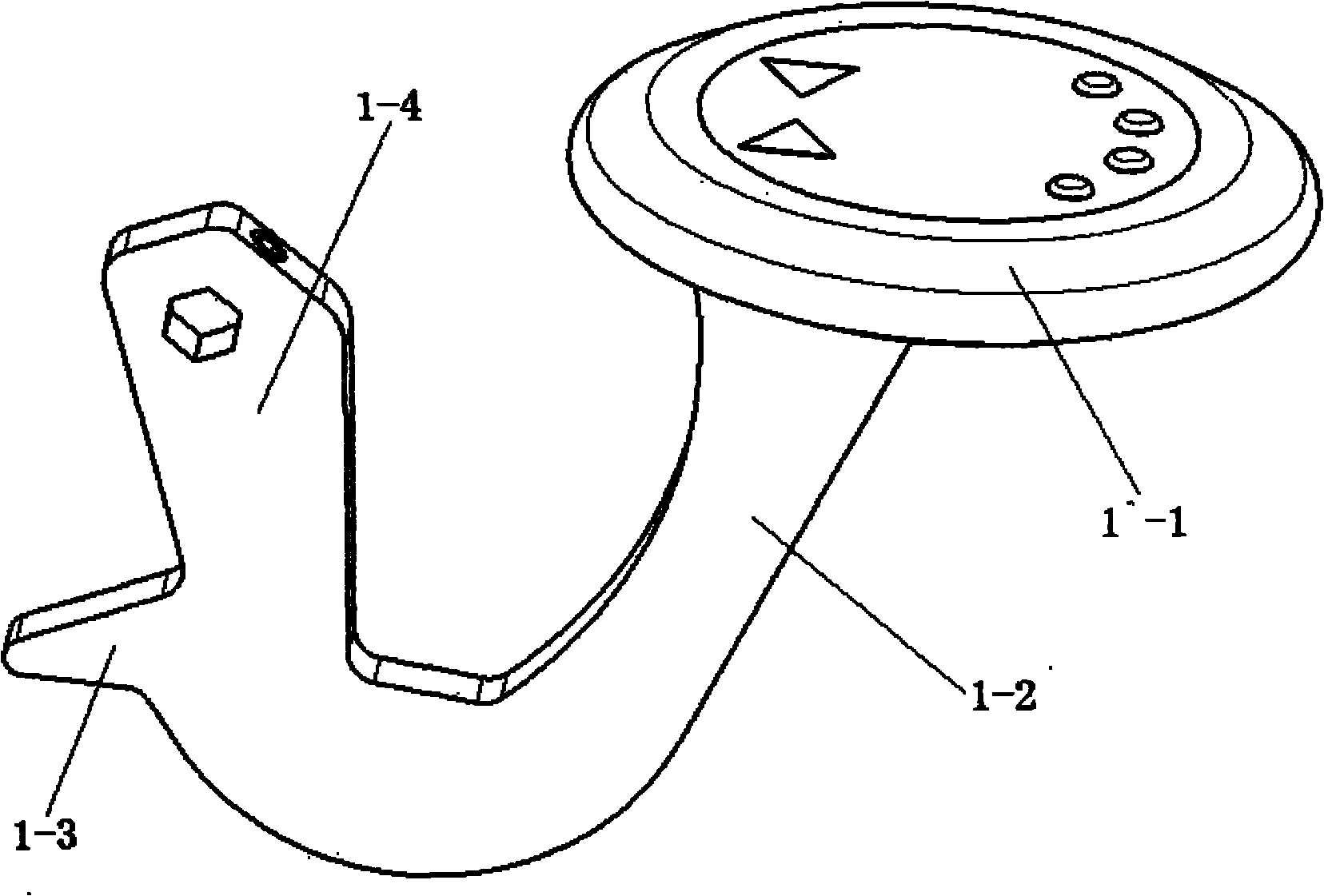

[0014] Such as figure 2 The pedal assembly 1 shown includes a rotating beam 1-4 and a support beam 1-2 supporting the pedal 1-1, and a cross beam 1-3 is arranged at the front end of the rotating beam 1-4.

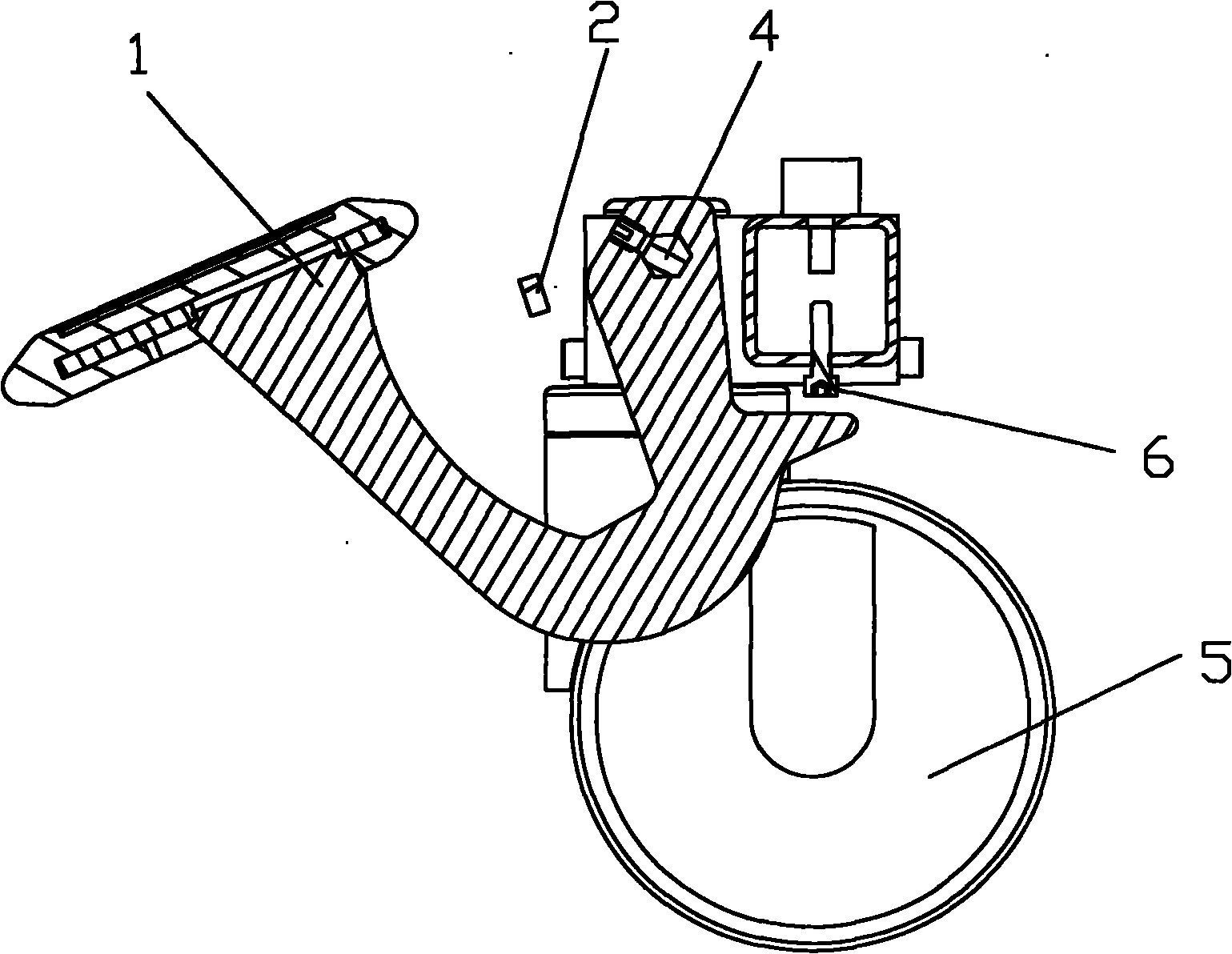

[0015] Such as image 3 The cross-sectional shape of the connecting rod 4 shown is a polygon; the cross-section of the connecting rod 4 is a regular hexagon; the lower part of the bracket 3 directly above the crossbeam 1-3 is provided with a limiting protrusion 6; the rotating A baffle 2 is arranged between the beam 1-4 and the support beam 1-2, and the baffle 2 is fixed on the support 3.

[0016] When the operator steps down on the pedal assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com