Film attaching method and device

A film sticking device and film sticking technology, which are applied in lamination devices, chemical instruments and methods, electrical components, etc., can solve the problems of unusable film, large waste, waste in the width direction, etc., to improve the quality of the film and improve the quality of the film. , the effect of reducing the likelihood

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

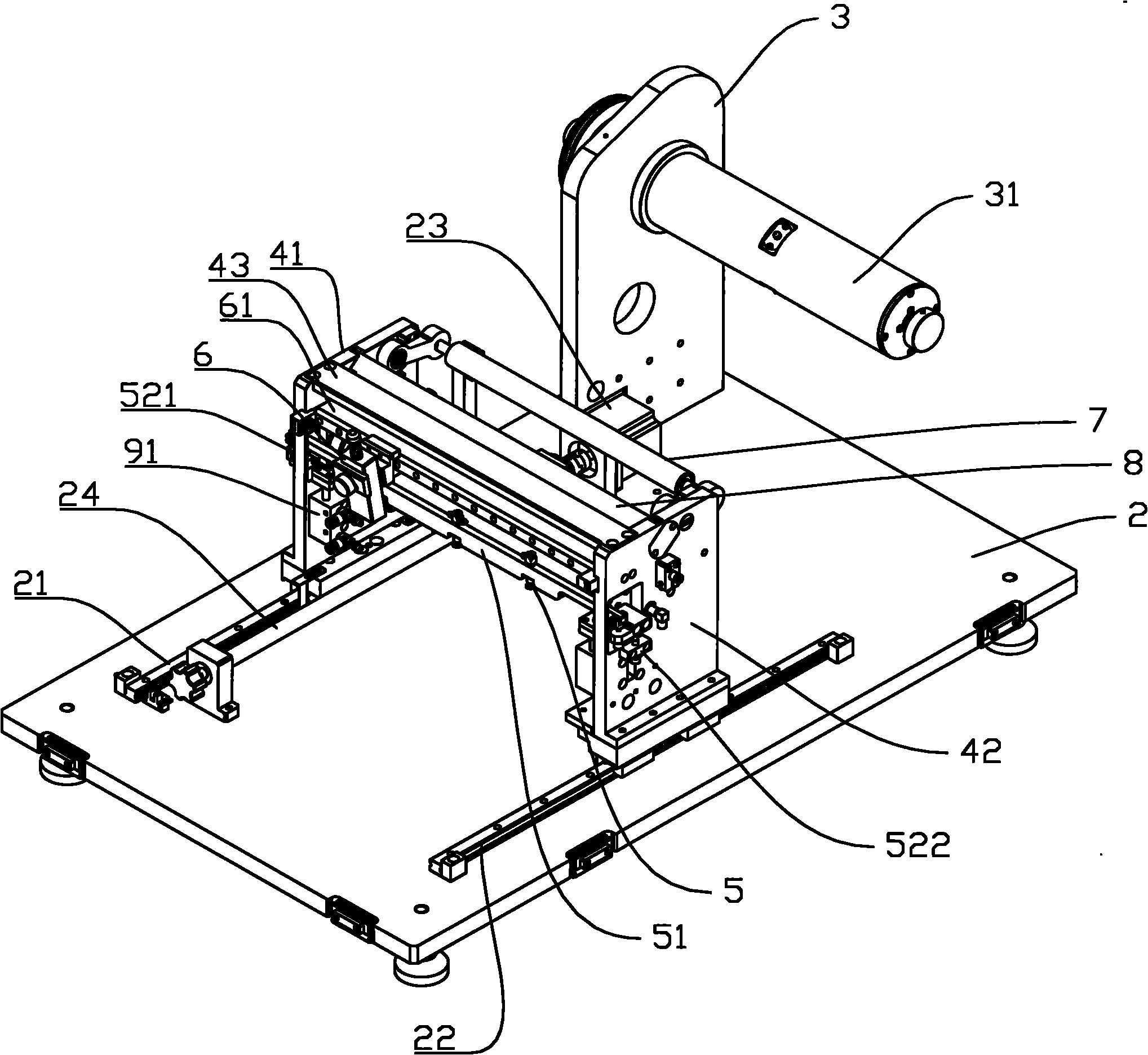

[0054] Film application devices, such as image 3 As shown, it includes a base 2 on which two rack boards (41, 42) are arranged at intervals and in parallel. The lower ends of the two rack plates (41, 42) are provided with guide grooves (not shown in the figure). Two guide rails (21, 22) are arranged on the base 2. The guide rail 21 cooperates with the guide groove at the lower end of the frame plate 41, so that the frame plate 41 can move along the guide rail 21 when driven. The guide rail 22 cooperates with the guide groove at the lower end of the frame plate 42, so that the frame plate 42 can move along the guide rail 22 when driven. The base 2 is provided with a motor 23 and a screw mandrel 24 . The output shaft of the motor 23 is connected with the screw mandrel 24, and the motor 23 can drive the screw mandrel 24 to rotate. The guide rails (21, 22) are horizontally arranged on the base 2, therefore, when the rack boards (41, 42) move, they also move in the horizontal ...

Embodiment 2

[0070] The difference between this embodiment and Embodiment 1 is that the second cross bar 61 , the knife holder 6 and the cutting knife 62 are omitted. When using this embodiment, if the film needs to be cut off, the operator can cut off the film with a cutting knife.

Embodiment 3

[0072] The difference between this embodiment and embodiment 2 is that, on the basis of embodiment 2, the expansion rod is omitted, and the purpose of the present invention can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com