Paste filling pipeline system for coal mine

A paste filling and pipeline system technology, which is applied to filling materials, mining equipment, safety devices, etc., can solve problems such as easy pipe blocking and filling system damage, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

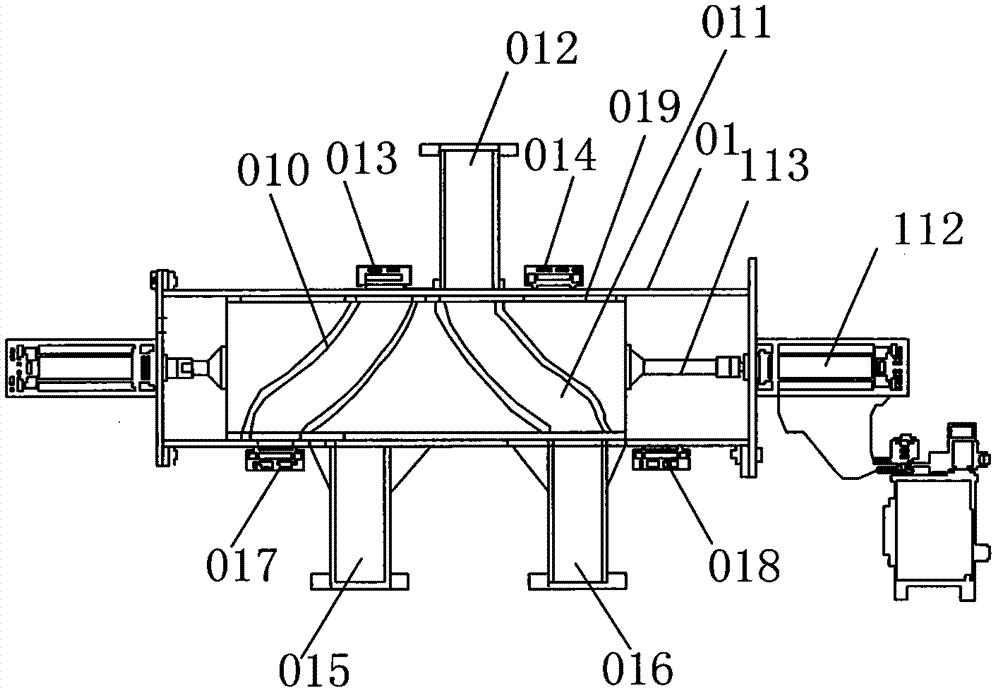

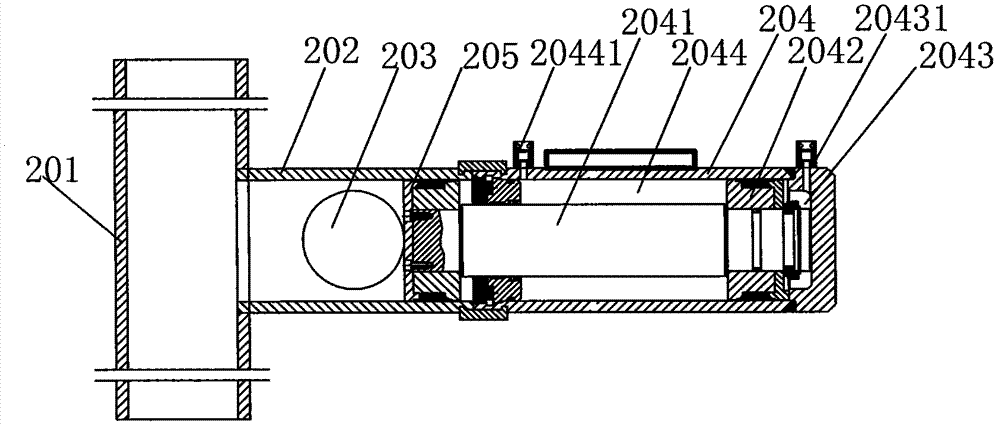

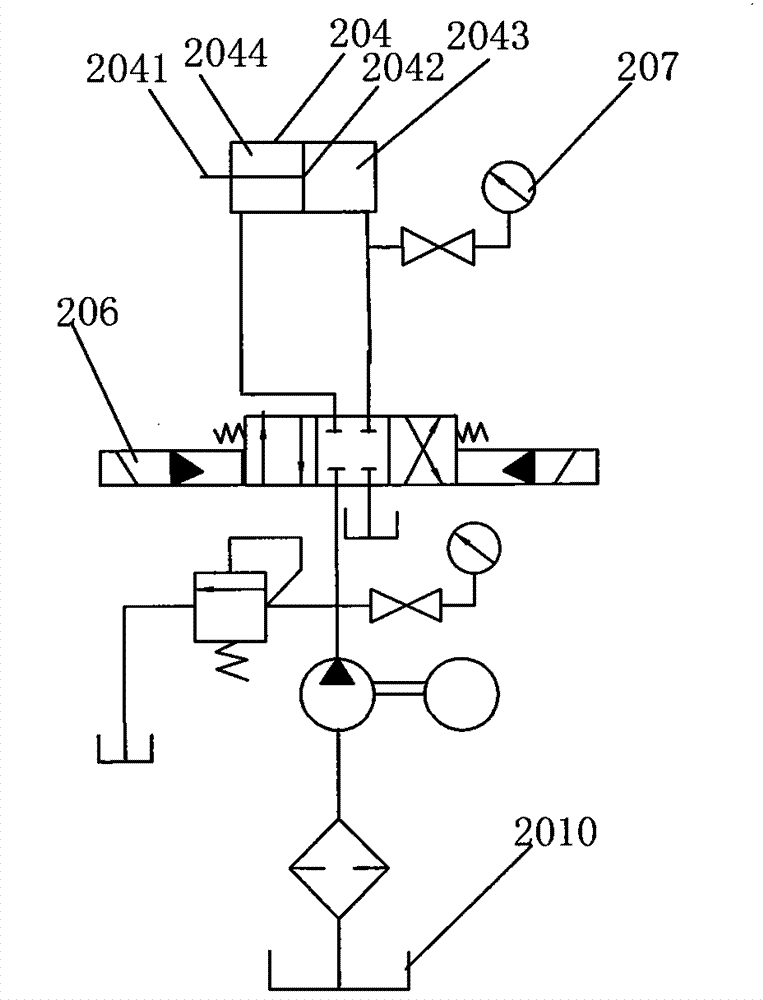

[0024] Below in conjunction with accompanying drawing, the present invention will be described in further detail, as appended Figure 1-Figure 7 As shown, a new type of paste filling pipeline system, including filling pump reversing equipment 1, paste filling plugging pipe discharge gate with pressure detection function 2, paste filling pipeline telescopic device 3, paste filling main line pipe The sewage valve 4 and the paste filling pipeline cleaning flow adjustment control device 5 are connected by straight pipes, pipe clips and tees.

[0025] The above-mentioned filling pump reversing equipment 1, as attached figure 1As shown, including the fixed bracket 01, the upper middle part of the fixed bracket 01 is provided with an upper nozzle 012 and two subsidiary upper nozzles 013 and 014, and the two subsidiary upper nozzles 013 and 014 are symmetrically arranged on the upper nozzle 012. On both sides and on the same axis as the upper nozzle 012; two lower nozzles 015 and 016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com