Low-entropy hybrid combustion circulating thermal power system

A thermal power and co-combustion technology, which is applied in the direction of turbine/propellant fuel delivery system, charging system, combustion engine, etc., can solve the problems of energy waste, inability to improve the thermal efficiency of thermal power system, and the problem of emission pollution that cannot be fundamentally solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

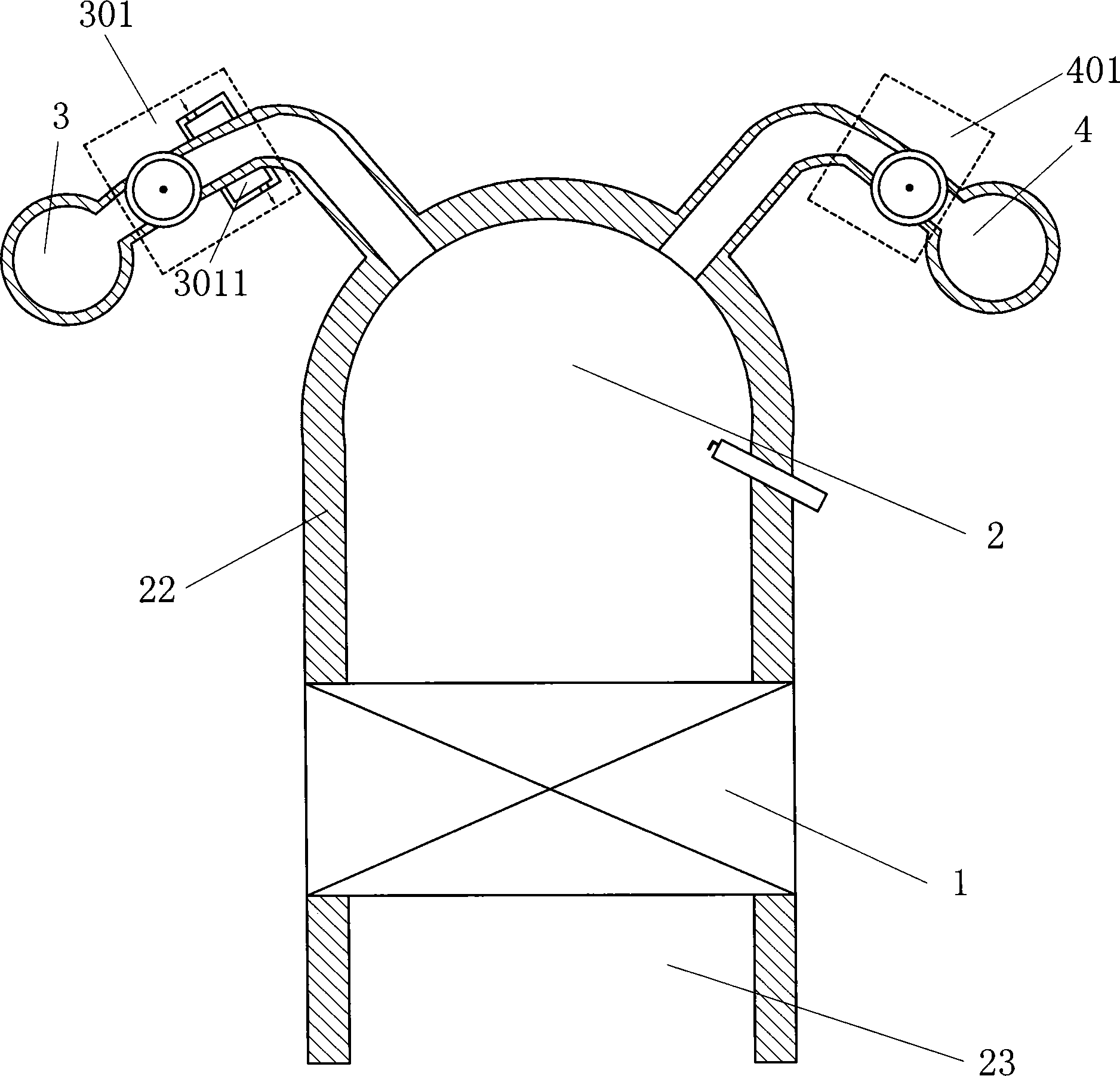

[0130] Such as figure 1 The low-entropy co-combustion cycle thermodynamic system shown includes a working mechanism 1, a combustion chamber 2, an oxygen source 3 and a fuel source 4, the oxygen source 3 communicates with the combustion chamber 2 through an oxygen high-pressure supply system 301, and the fuel source 4 passes through The fuel high-pressure supply system 401 communicates with the combustion chamber 2, and an oxygen heat-absorbing heat exchanger 3011 is installed in the oxygen high-pressure supply system 301, and the oxygen in the oxygen source 3 absorbs heat in the oxygen heat-absorbing heat exchanger 3011 to form high-pressure gaseous oxygen Entering the combustion chamber 2, the minimum pressure bearing capacity of the oxygen high-pressure supply system 301 is greater than or equal to 2MPa; the combustion chamber 2 communicates with at least one working mechanism 1, and the working mechanism 1 outputs power to the outside. The oxygen source 3 is set as a cryog...

Embodiment 2

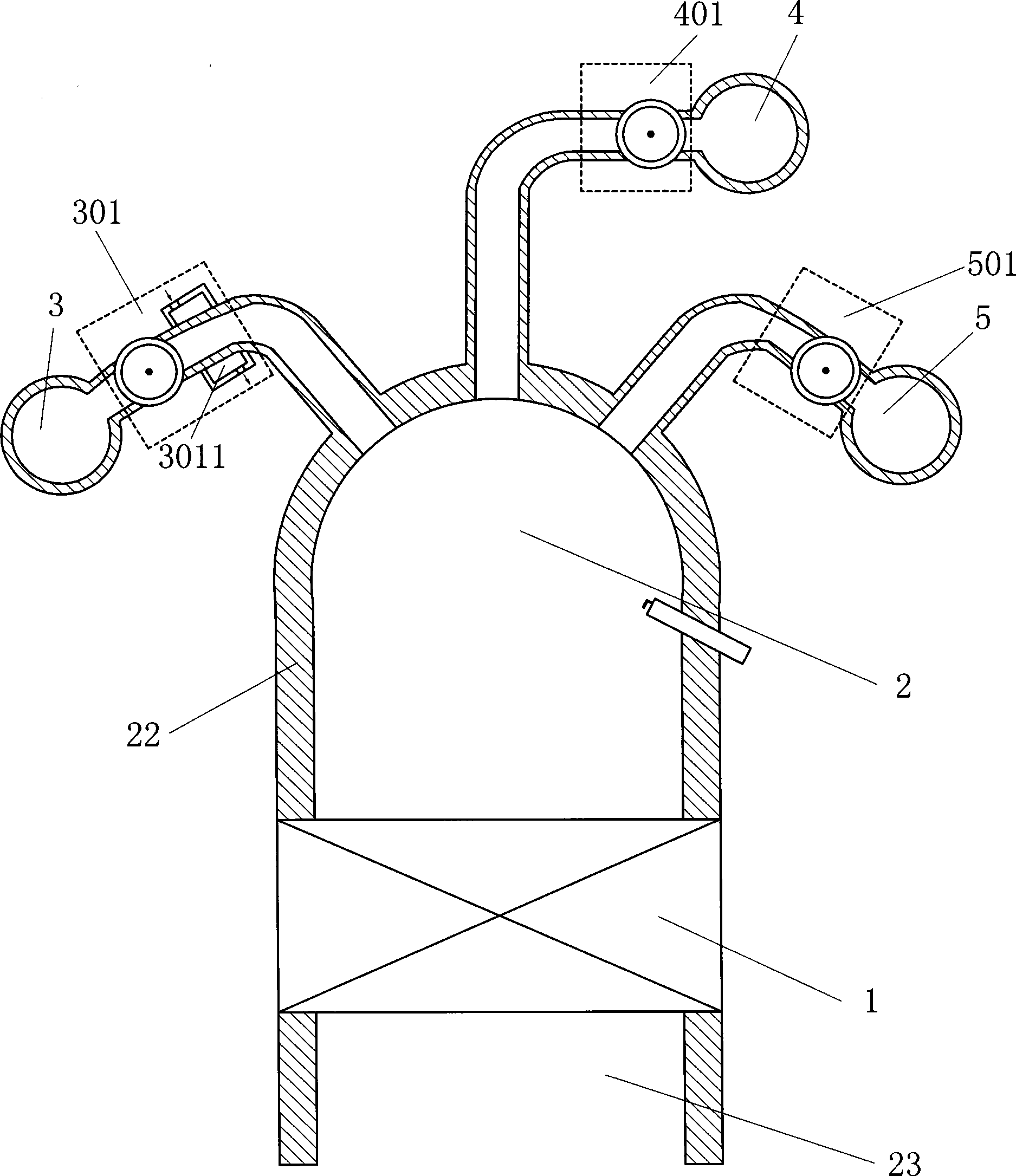

[0132] Such as figure 2 The low-entropy co-combustion cycle thermodynamic system shown includes a working mechanism 1, a combustion chamber 2, an oxygen source 3, a fuel source 4 and an expansion agent source 5, and the oxygen source 3 communicates with the combustion chamber 2 through an oxygen high-pressure supply system 301 , the fuel source 4 communicates with the combustion chamber 2 through the fuel high-pressure supply system 401, and the expansion agent source 5 communicates with the combustion chamber 2 through the expansion agent high-pressure supply system 501; an oxygen heat-absorbing heat exchanger is set in the oxygen high-pressure supply system 301 3011, the oxygen in the oxygen source 3 absorbs heat in the oxygen heat-absorbing heat exchanger 3011 to form high-pressure gaseous oxygen and enters the combustion chamber 2; the minimum pressure bearing capacity of the oxygen high-pressure supply system 301 and / or the expander high-pressure supply system 501 is grea...

Embodiment 3

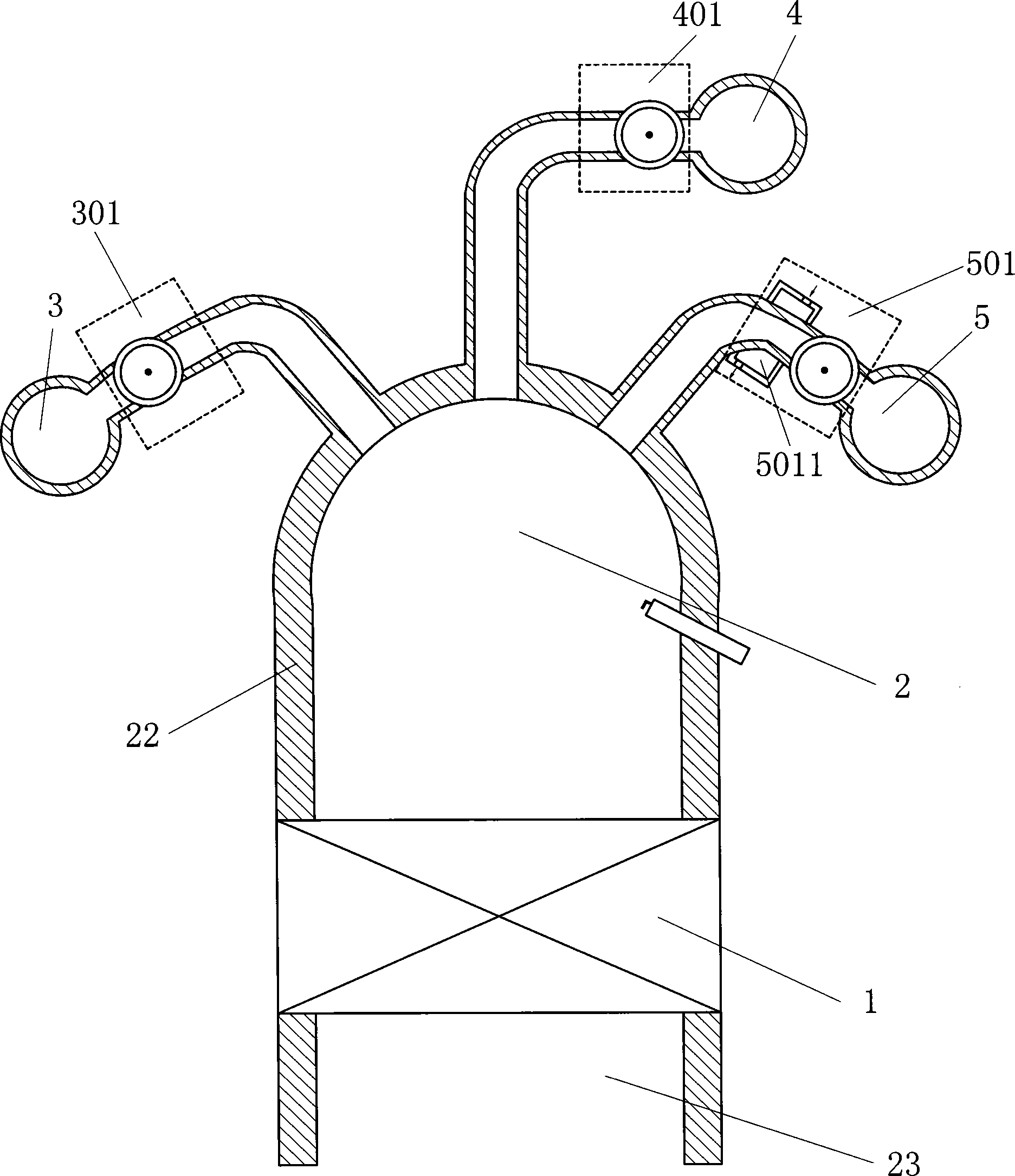

[0134] Such as image 3 The low-entropy co-combustion cycle thermodynamic system shown includes a working mechanism 1, a combustion chamber 2, an oxygen source 3, a fuel source 4 and an expansion agent source 5, and the oxygen source 3 communicates with the combustion chamber 2 through an oxygen high-pressure supply system 301 , the fuel source 4 communicates with the combustion chamber 2 through the fuel high-pressure supply system 401, and the expansion agent source 5 communicates with the combustion chamber 2 through the expansion agent high-pressure supply system 501; Exchanger 5011, the expansion agent in the expansion agent source 5 absorbs heat in the expansion agent heat-absorbing heat exchanger 5011 to form a high-pressure gaseous expansion agent and enters the combustion chamber 2; the oxygen high-pressure supply system 301 and / or the expansion agent high-pressure supply system 501 The minimum pressure bearing capacity is greater than or equal to 4MPa; the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com