Low-resistance-value sheet-type negative-temperature-coefficient thermal resistor with horizontal structure and manufacturing method thereof

A negative temperature coefficient, thermistor technology, applied in the direction of resistors with negative temperature coefficient, resistance manufacturing, resistors, etc., can solve the problems of multi-layer NTC thermistors that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described below in conjunction with specific embodiments and with reference to the drawings.

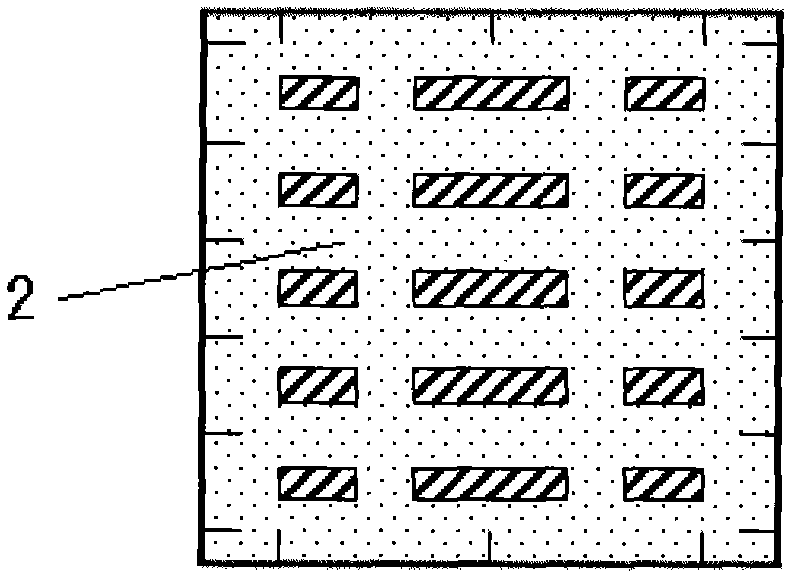

[0046] Kind of like Figure 1~4 The low-resistance chip type negative temperature coefficient thermistor shown in the horizontal structure is made into a surface-mounted structure using a printed circuit board process, including an NTC thermistor chip and terminal electrodes 4. The manufacturing method includes an NTC thermistor chip manufacturing method and a terminal electrode manufacturing method.

[0047] The manufacturing method of NTC thermistor chip includes the manufacturing of multilayer laminated sheet blanks, and the steps of sequentially lamination from bottom to top are as follows;

[0048] 1) Stack a piece of green film 3 printed with cutting dimension lines;

[0049] 2) Stack the lower substrate composed of n1=9 blank green film 1 and a green film 2 printed with internal electrodes on the surface of a blank green film 1 at the end, n1=9 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com