Process for producing filter rod by utilizing KDF4 forming unit

A molding unit, KDF4 technology, applied in the application, smoke oil filter, tobacco and other directions, can solve the problem of internal stress non-equilibrium characteristics and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

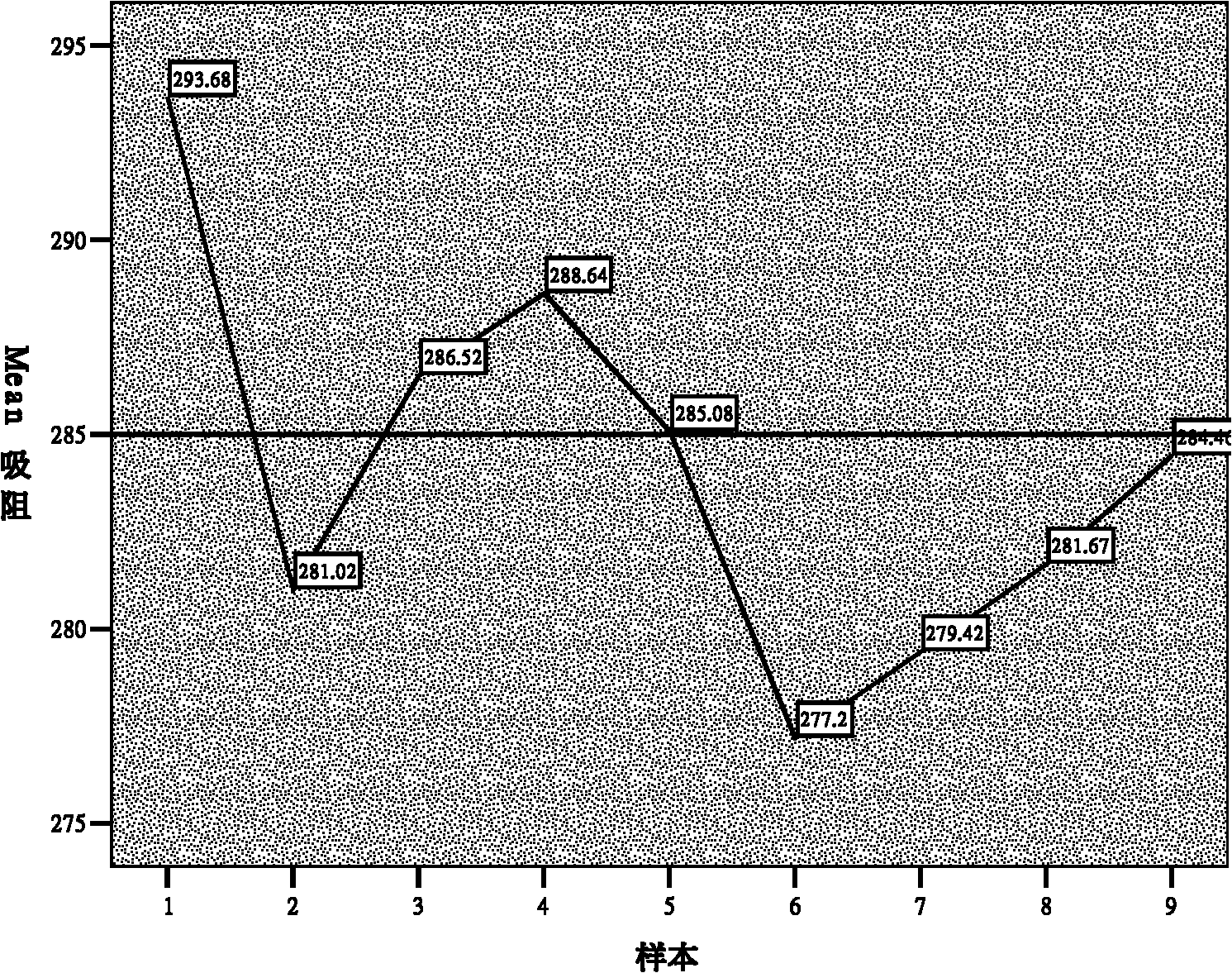

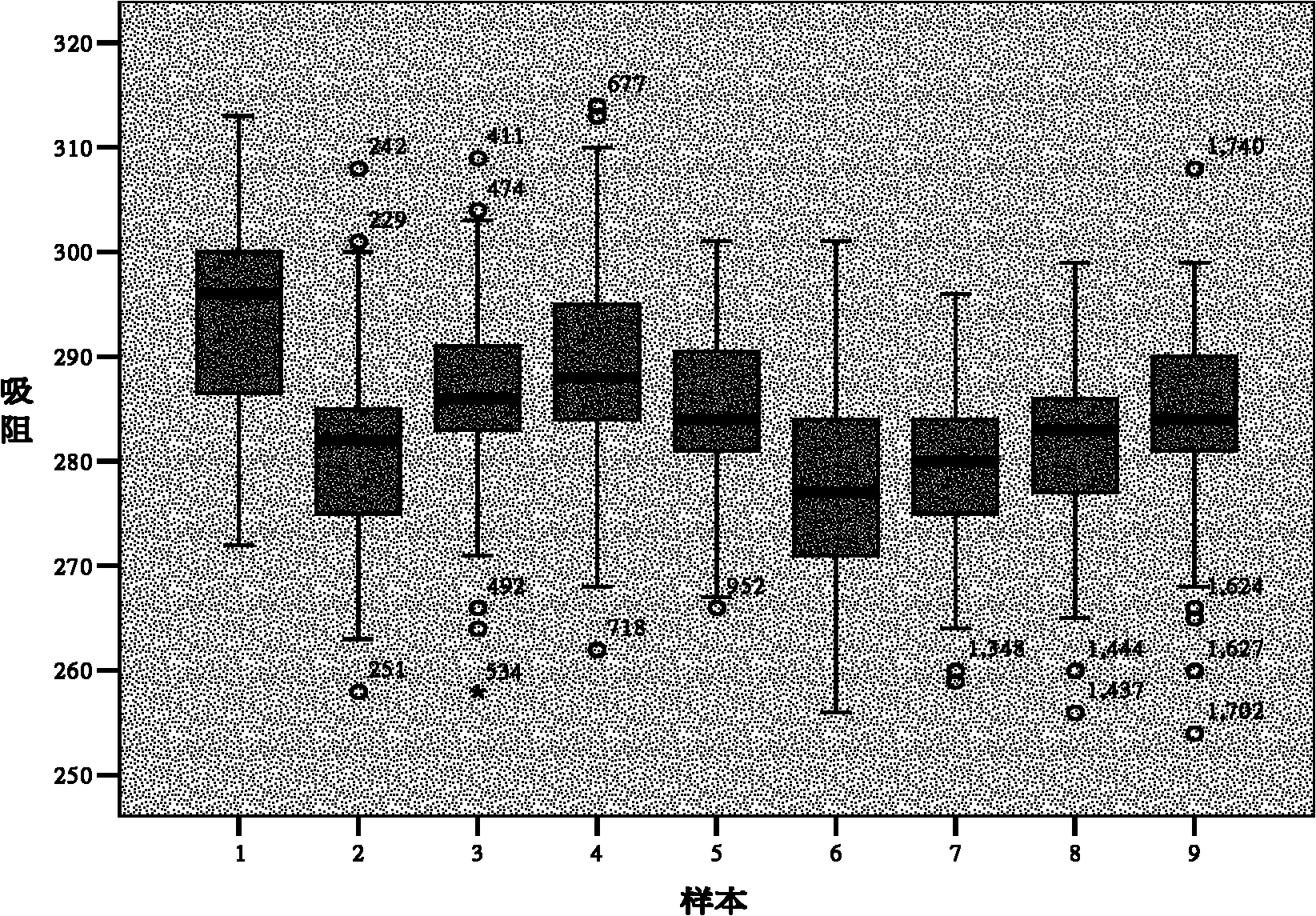

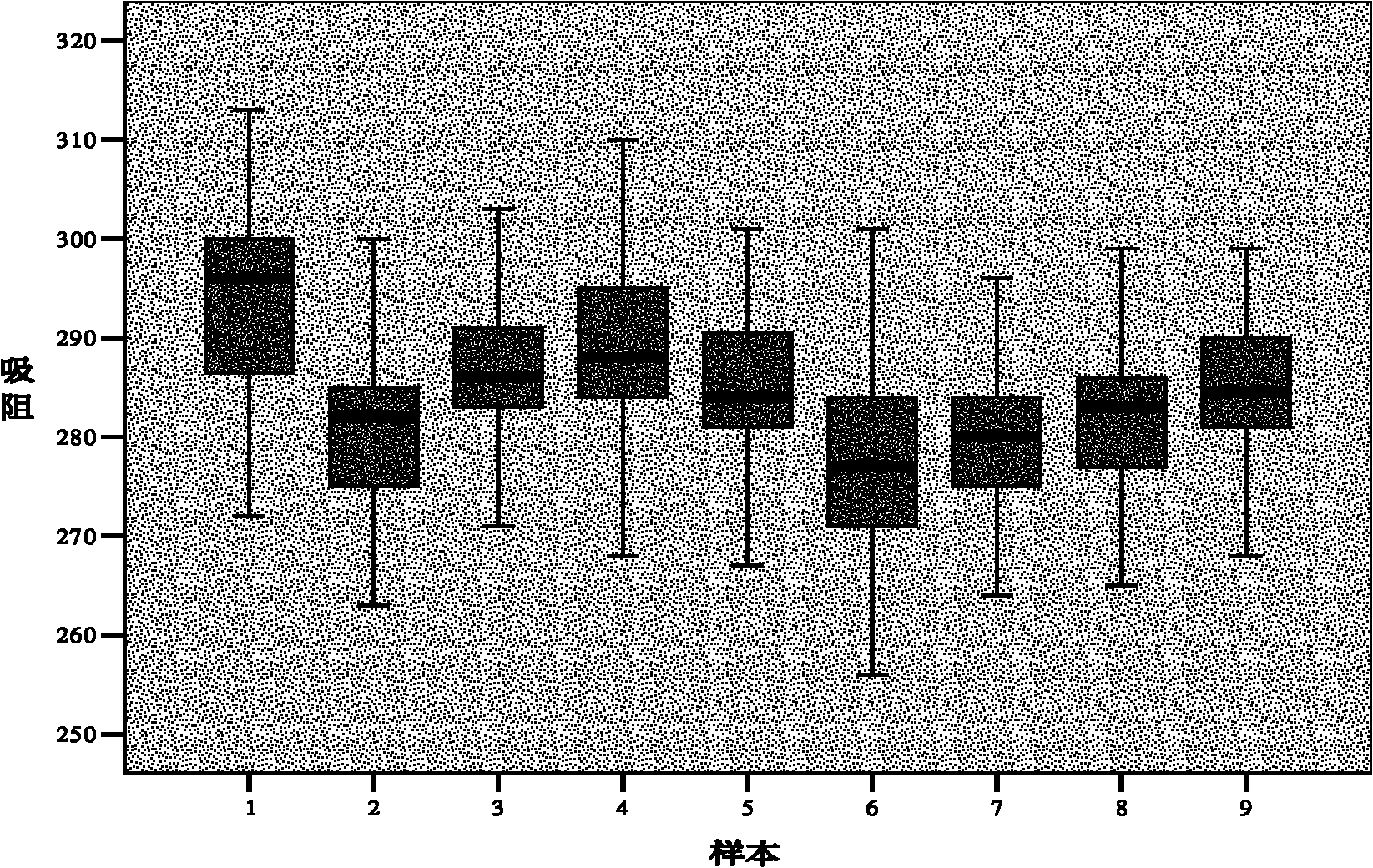

[0069] Single factor test of embodiment 1 KDF4 unit

[0070] The main purpose of this stage of work is to evaluate the influence of KDF4 unit adjustment parameters P1, V2 / V1, P0, V3 / V2 settings on the filter rod suction resistance processing performance, and finally determine the necessary parameters in the follow-up comprehensive test plan according to the strength of the influence ability. adjustment factor.

[0071] 1 Materials and methods

[0072] 1.1 Test equipment, instruments and materials

[0073] Selection specifications are 3.5Y34000 tow, 3.0Y35000 two kinds of tow (manufactured by Nantong Acetate Fiber Co., Ltd.), 26.5mm*30g*5000m forming paper (Sichuan Hengfeng Paper Industry), triacetin (Jinan Huayang Company) ).

[0074] KDF4 / AF4 molding unit, QTM filter rod performance comprehensive testing platform (Cerulean, UK), 30cm steel ruler (Nanchang Aerospace Modern Scientific and Educational Instrument Factory), stopwatch (Shanghai Stopwatch Factory), constant tempe...

Embodiment 2

[0140] The process parameter optimization experiment of embodiment 2KDF4 formed filter rod

[0141] According to the analysis results of the first phase of single factor test, the influence factors of P1 pressure and V3 / V2 will be eliminated in this phase of the test, and V2 / V1 and P0 will be selected as the key factors of this phase of the test. The tow opening width related to the rod hardness was added into the test considerations, and six specifications of acetate tows including 3.0Y35000, 3.5Y34000, 3.9Y31000, 3.0Y32000, and 2.4Y34000 were tested in the KDF4 forming unit.

[0142] The first section 3.0 / 35000 specification tow

[0143] 1 Materials and methods

[0144] 1.1 Test equipment, instruments and materials

[0145] Selection specification is 3.0Y35000 tow (manufactured by Nantong Acetate Fiber Co., Ltd.), 26.5mm*30g*5000m forming paper (Sichuan Hengfeng Paper Industry), triacetin (Jinan Huayang Company).

[0146] KDF4 / AF4 molding unit, QTM filter rod performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com