High-pressure experimental system for simulating leakage type natural gas hydrate formation/decomposition

A high-pressure experiment, hydrate technology, applied in the methods of chemically changing substances by atmospheric pressure, chemical/physical processes, chemical instruments and methods, etc. Problems such as the scope and the lack of experimental test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

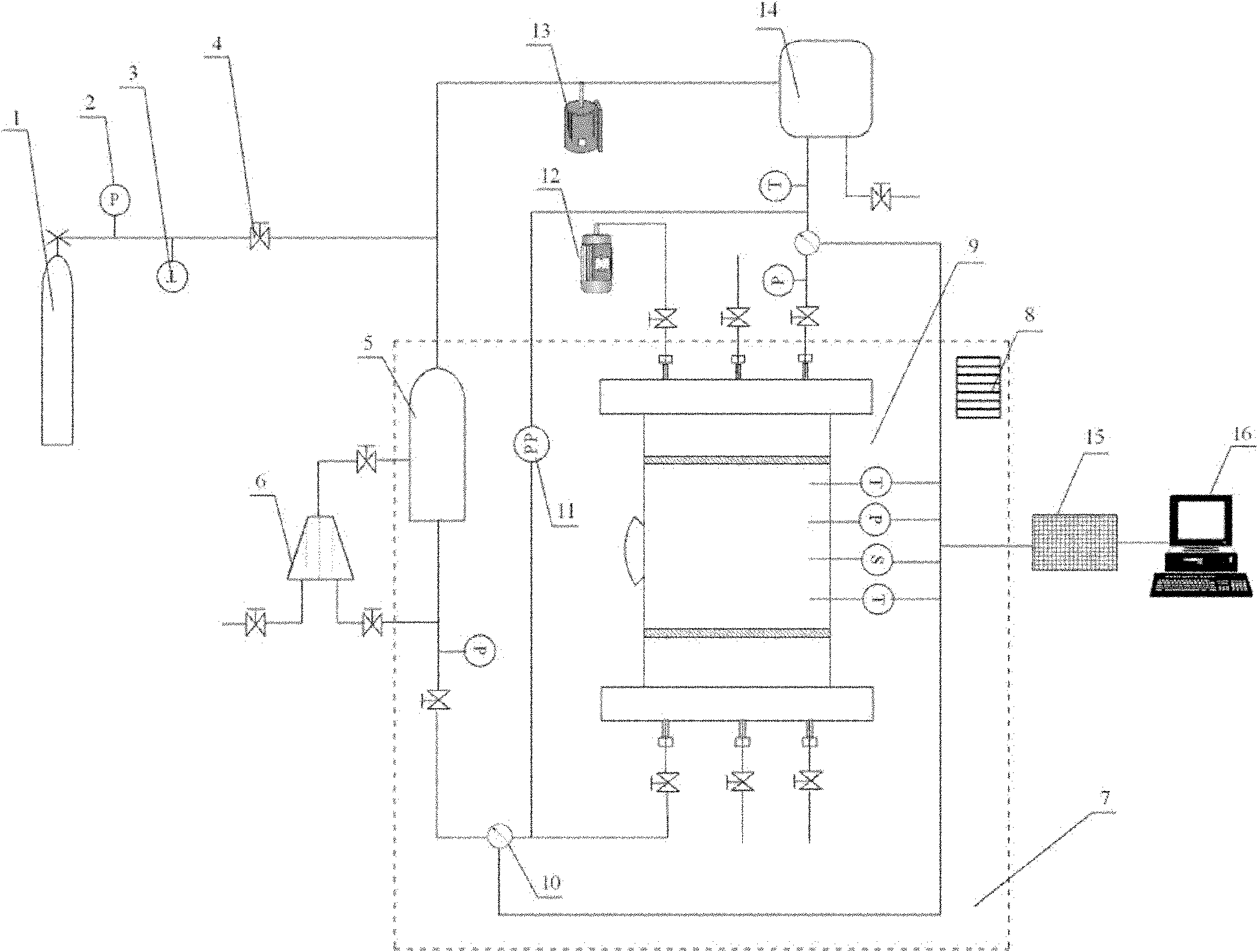

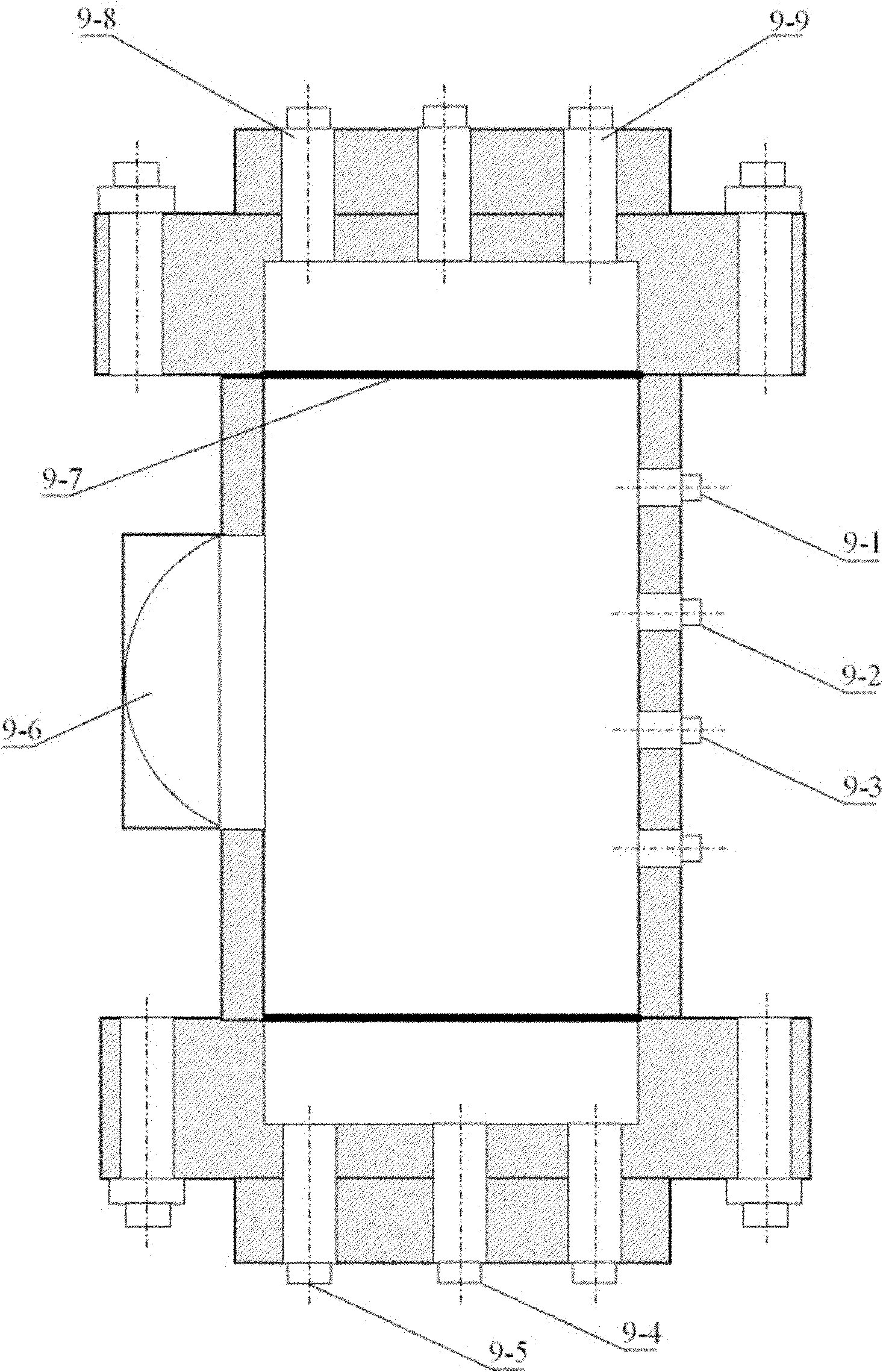

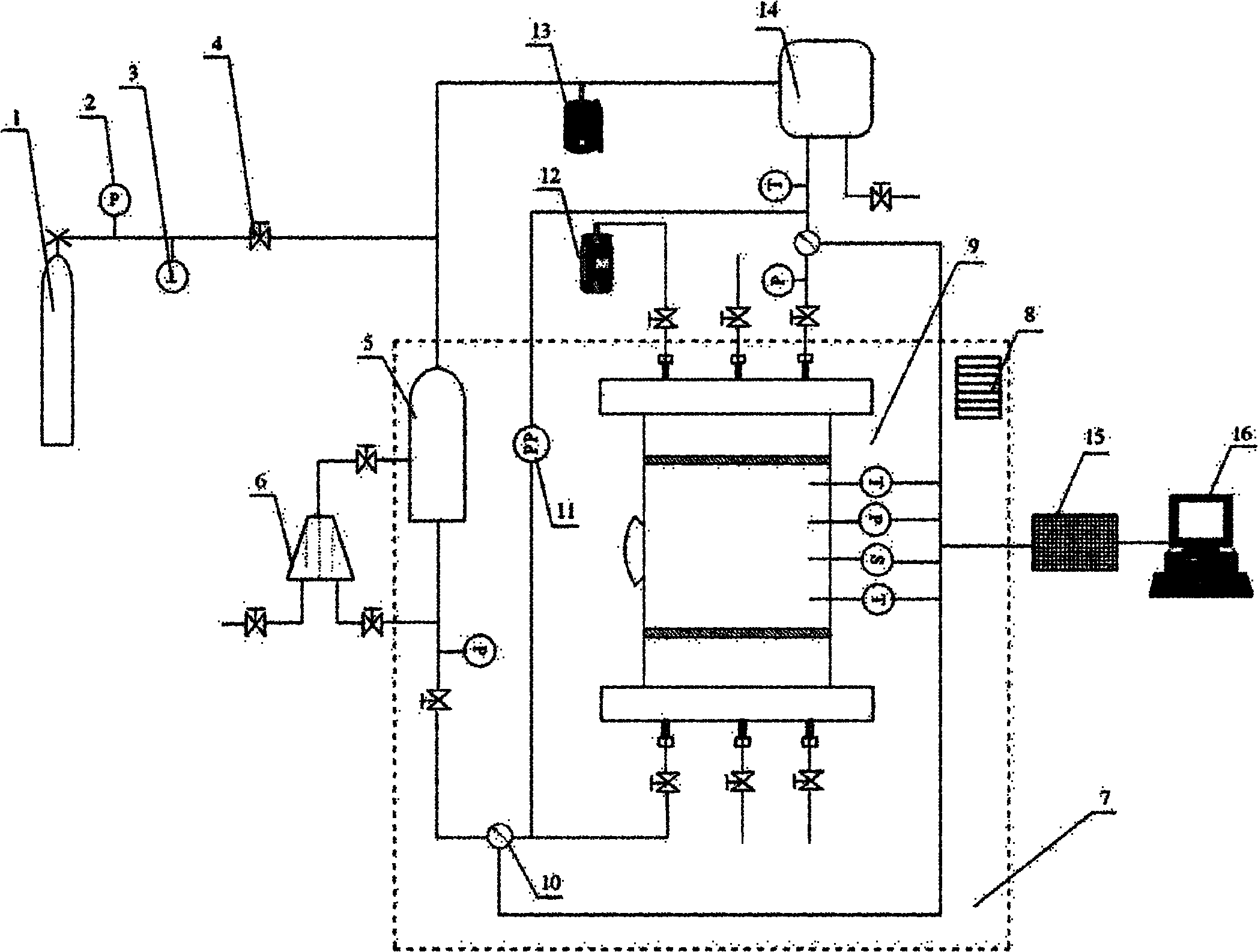

[0019] see figure 1 As shown, a high-pressure experimental system for simulating the formation / decomposition of seepage-type natural gas hydrates includes a visualized large-volume high-pressure transparent reactor 9, which is connected to the reactor 9 and provides the required pressure, temperature and humidity for the reactor 9 The gas supply system of flowing gas; The temperature control system that provides required temperature and humidity for reactor 9; Be connected with reactor 9 and provide vacuum environment and the power system that guarantees the smooth circulation of gas for it; And be connected with reactor 9, real-time A data acquisition system for collecting temperature, pressure, conductivity and flow data and recording and processing data observation tests.

[0020] The gas supply system provides the experimental system with flowing gas under suitable pressure, temperature and humidity. In the pipeline where the gas enters the reaction kettle 9 from the high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com