Roll gap control method for soft reduction technology for continuous casting

A control method and light reduction technology, applied in the field of continuous casting light reduction roll gap control, which can solve the problems of displacement feedback signal distortion and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

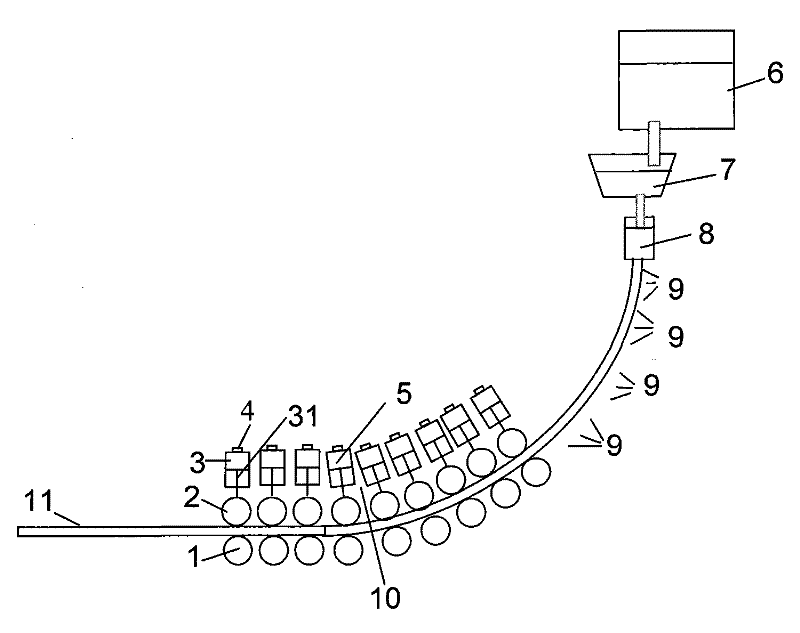

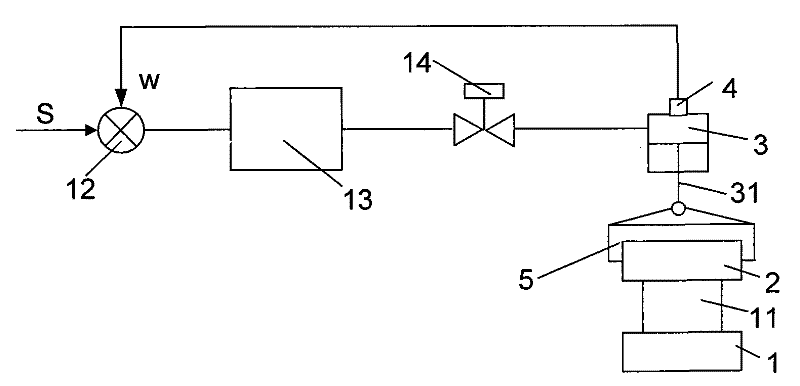

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

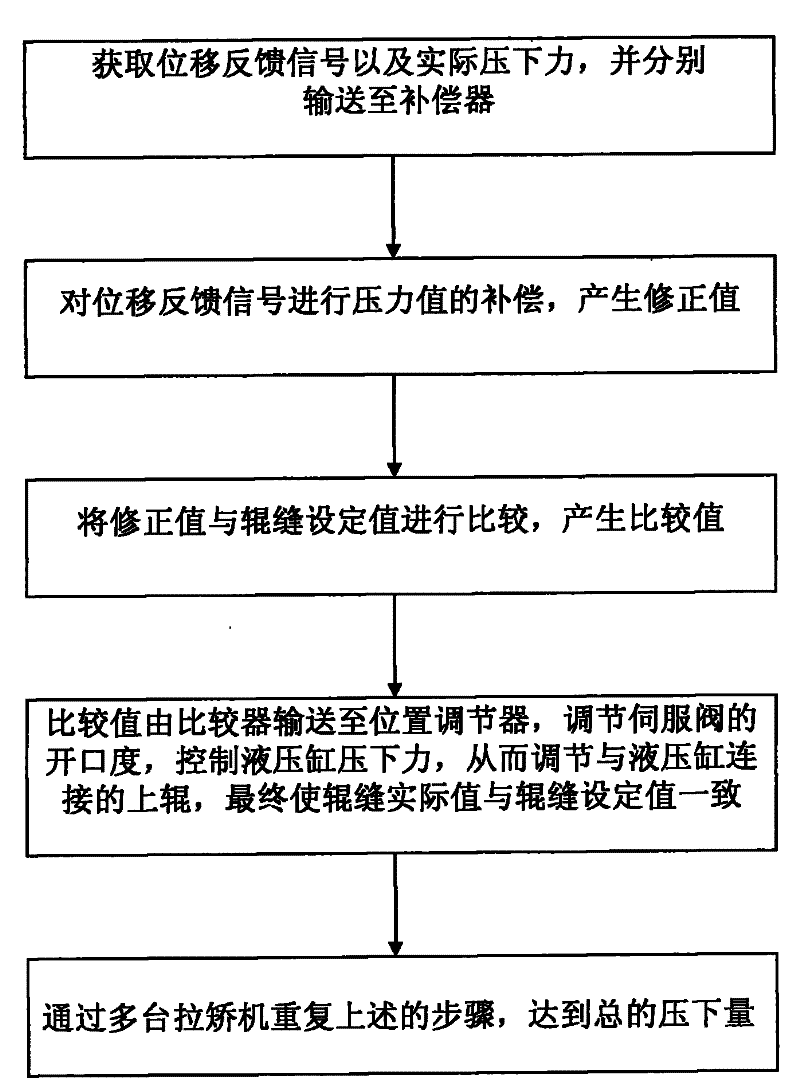

[0041] see image 3 , Figure 4 As shown, a continuous casting light reduction roll gap control method, the specific steps of the control method are:

[0042] a. The displacement feedback signal W and the actual pressing force F of the upper roller 2 of the tension leveler 5 are respectively obtained through the displacement sensor 4 and the pressure sensor 16, and are respectively sent to the compensator 15. It should be noted here that the pressure sensor 16 is set On the hydraulic cylinder 3 of the upper roll 2, the compensator 15 is connected between the sensor and the comparator 12;

[0043] b. Compensate the pressure value of the displacement feedback signal W, generate a correction value C, and send the correction value C to the comparator;

[0044] c. Compare the correction value C with the roll gap setting value S ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com