Robot system having positioner

A robot system and positioner technology, applied in the field of robot systems, can solve the problems of larger working space, larger factory space, and higher air-conditioning costs, and achieve the effect of reducing air-conditioning costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

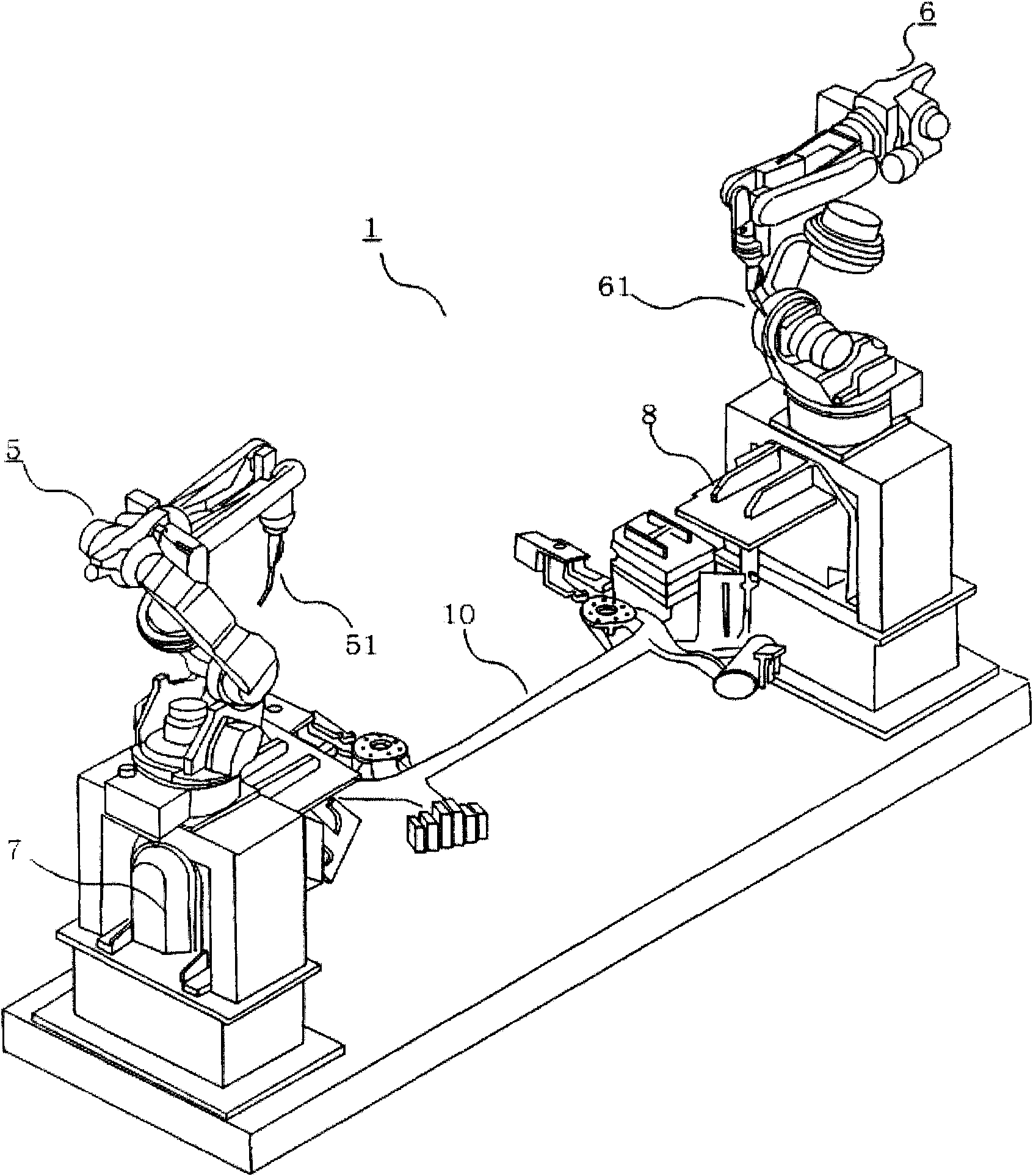

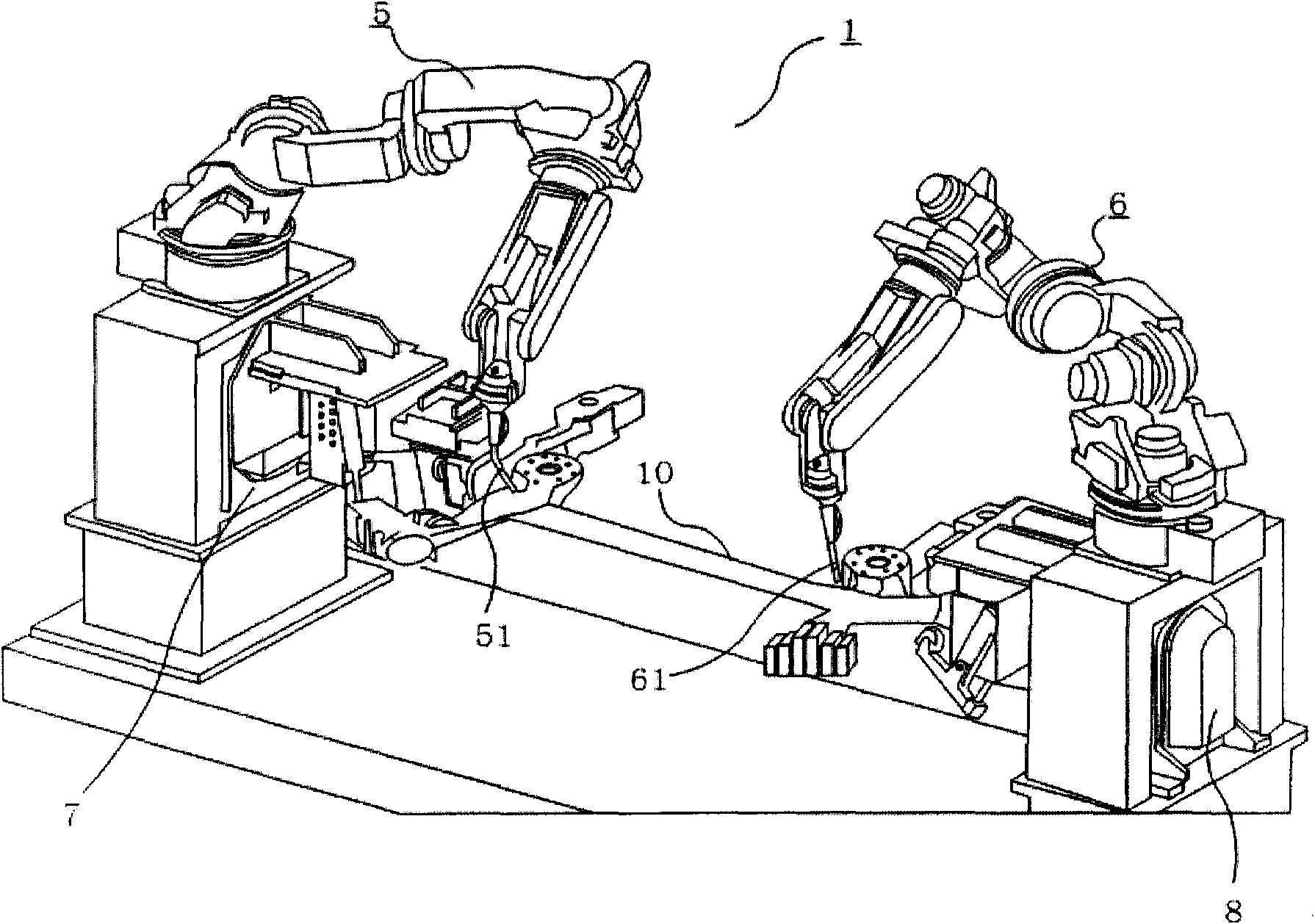

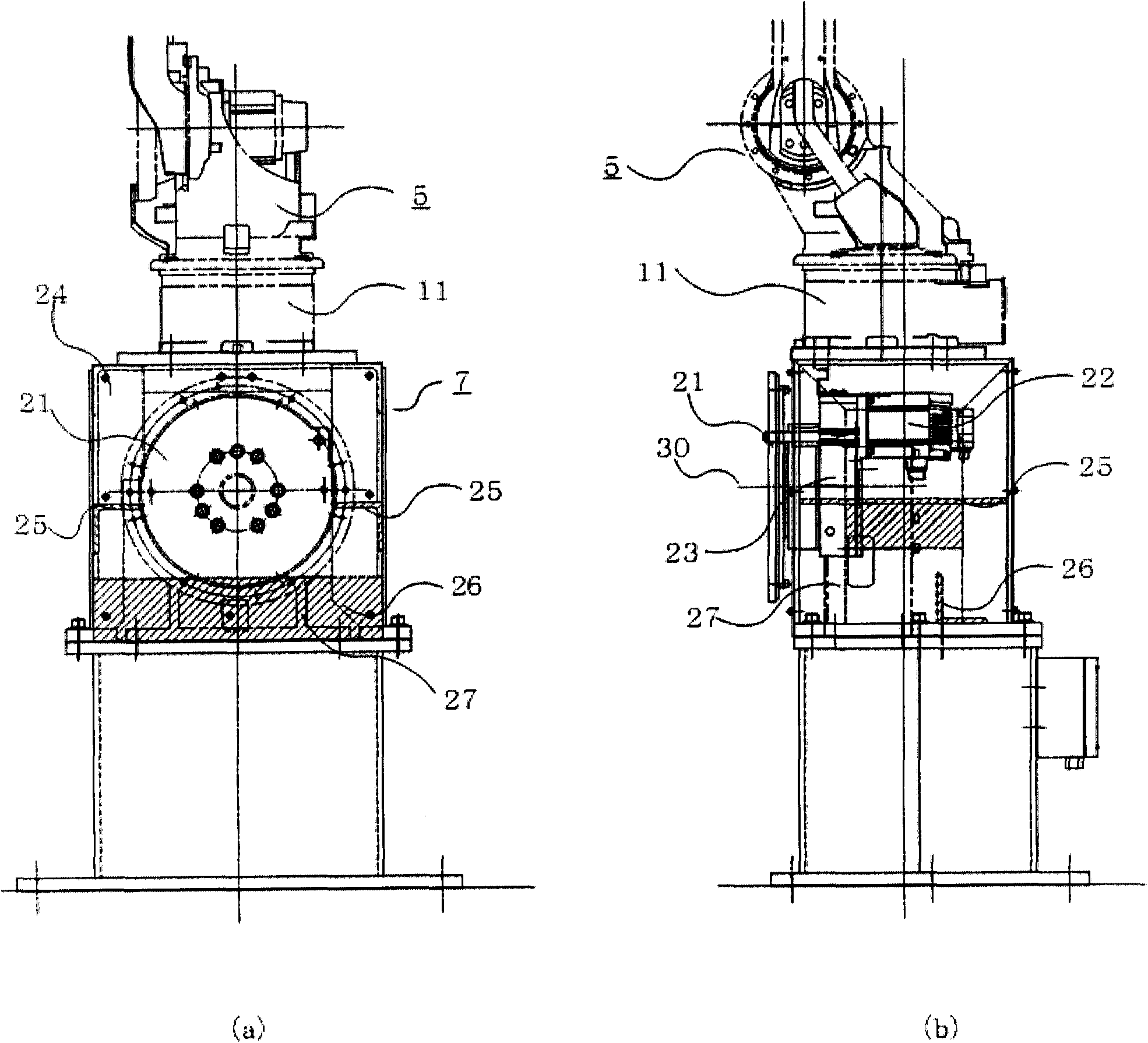

[0021] Such as figure 1 As shown, the work object 10 is, for example, a long-sized object such as a chassis of an automobile, and is attached to the first positioner 7 and the second positioner 8 in the first welding process by a transfer robot (not shown). Next, the first positioner 7 and the second positioner 8 are rotated so as to align with the welding position, and the first welding robot 5 and the second welding robot 6 weld a predetermined position. When the welding is completed, the transfer robot 9 is placed on a not-shown workbench. Next use figure 1 and figure 2 The first welding process will be described in detail as an example. figure 1 is a perspective view of the welding robot when it is in the standby position, figure 2 It is a perspective view during welding. Such as figure 1 As shown, in the first welding process 1, the first welding robot 5 and the second welding robot 6 are arranged on the first positioner 7 and the second positioner 8, respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com