Method and device for turning tiles

A tile and brick turning technology, which is applied in the field of tile turning devices, can solve the problems of lower production efficiency of the assembly line, tile bumps, tile surface defects, etc., and achieve the advantages of saving time for turning bricks, simple mechanism, low purchase cost and low use cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

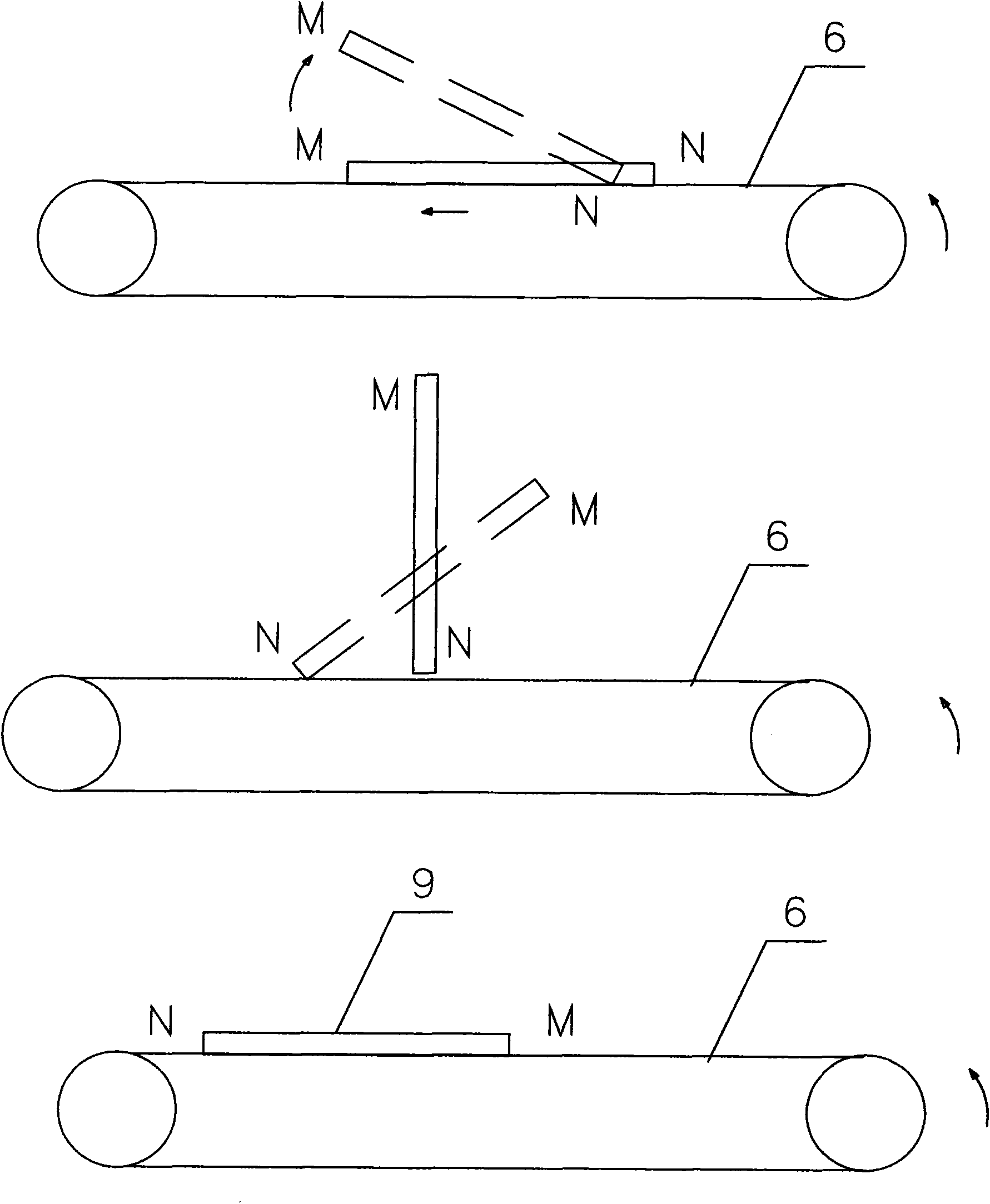

[0026] Such as figure 1 As shown, the brick turning process described in the present invention is as follows: the tile 9 moves forward together with the upper brick conveyor belt 6, and when the tile 6 enters the brick turning area, the front part M of the tile 6 is gradually lifted upwards by using a brick turning device. After the tile rear end N moves forward together with the upper brick conveyor belt, after the tile 6 is erected to a vertical state, the lower end N of the tile continues to move forward together with the upper brick conveyor belt 6, and the upper end M of the tile 9 gradually falls, finally Lay on the brick conveyor belt 6 to complete the brick turning process.

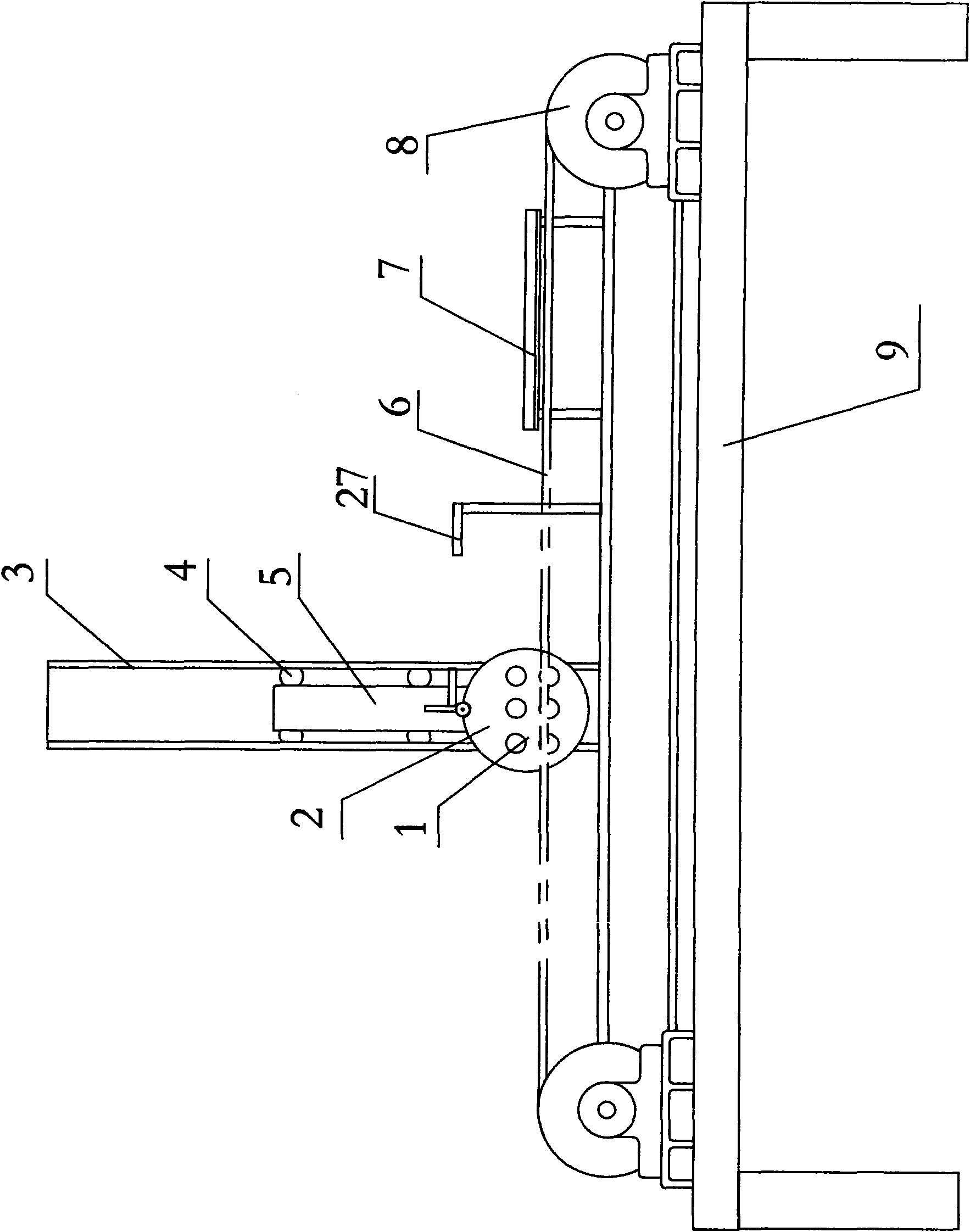

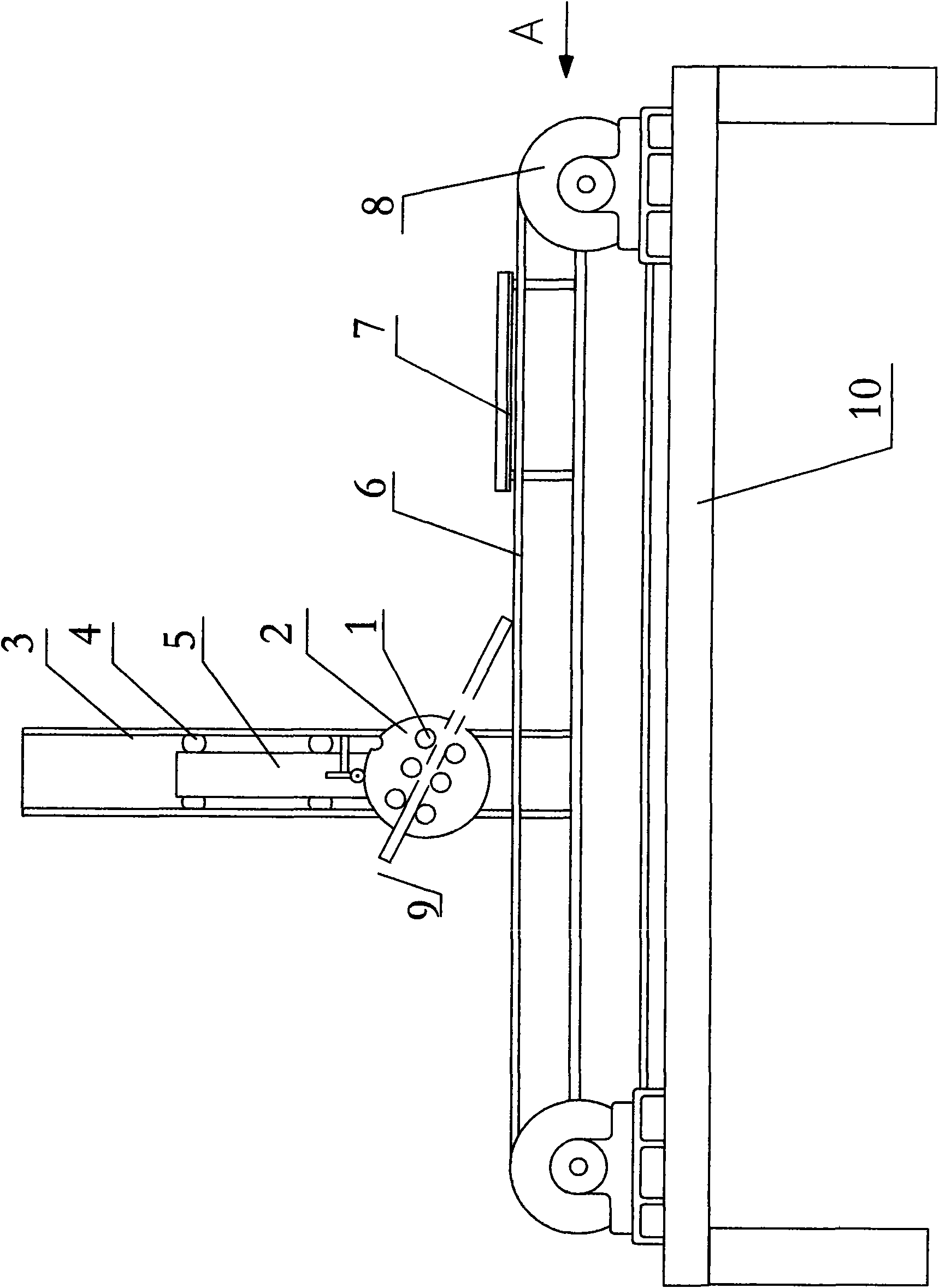

[0027] Set forth below the structure of brick turning device shown in the present invention:

[0028] Such as Figures 1 to 8 Shown, brick turning support 2 and vertical pull frame 5 are set on the side of brick conveyer belt 6, fixed small shaft on vertical pull frame 5, and brick turning suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com