Floor plate connector and floor plate connection structure

A technology for connecting structures and connecting parts, applied in the field of building decoration materials, can solve problems such as crack expansion at joints, and achieve the effects of reliable sealing, difficult displacement and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

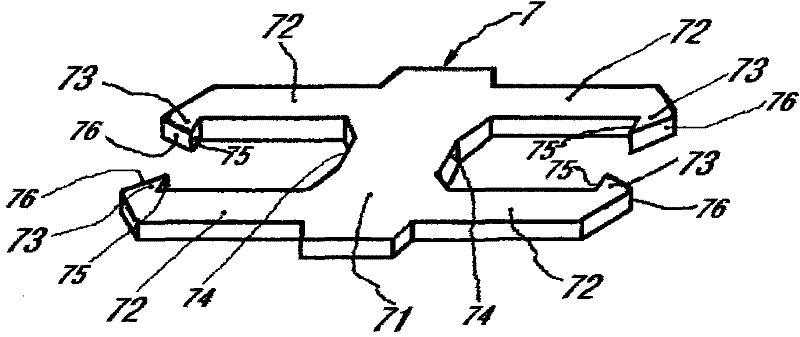

[0026] Embodiment 1: as figure 1 As shown, a deck connector 7 includes a mother body 71 and a pair of inserting arms 72 are arranged symmetrically on both sides of the mother body 71. The inserting arms 72 are parallel to each other and extend outward from the mother body 71. The inserting arms 72 An outwardly protruding card body 73 is formed on the free end, and the free ends of the inserting arms 72 can move elastically with each other. The card body 73 on the insertion arm 72 on the same side of the mother body 71 is arranged opposite to each other. The card body 73 is formed with two sides, one of which is formed with a first slope 76 extending limitedly from the end of the card body to the direction of the mother body. One side is formed with a first contact surface 75 capable of engaging with the surface of other objects; the two sides of the mother body 71 between the two inserting arms 72 form a second contact surface 74 respectively. Two opposite first slopes 76 for...

Embodiment 2

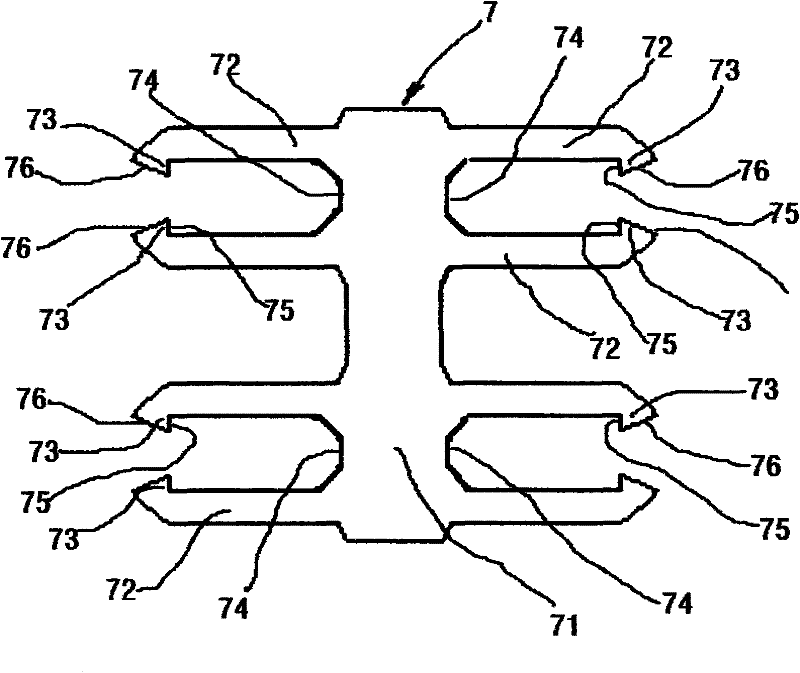

[0027] Embodiment 2: as figure 2 As shown, it is illustrated that a number of inserting arms 72 can be arranged on both sides of a mother body 71 according to the actual situation, but at least one pair of inserting arms 72 have card bodies 73 opposite to each other. Such as figure 2 As shown, two pairs of inserting arms 72 are arranged symmetrically on both sides of the mother body 71 , and the card bodies 73 on the ends of at least one pair of inserting arms 72 are oppositely arranged.

Embodiment 3

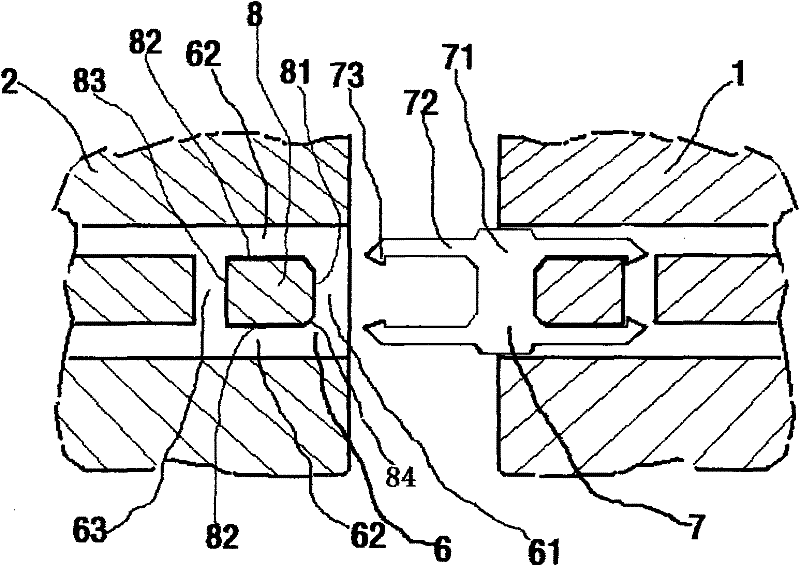

[0028] Embodiment 3: as image 3In the decking connection structure shown, the adjacent first decking 1 and second decking 2 are connected through the decking connector 7, and the respective side ports of the decking 1 and the decking 2 are respectively provided with the corresponding joints of the decking connector 7. Adapted connection groove 6, the connection groove 6 is composed of a mother groove 61, a card body groove 63 and two parallel insertion grooves 62, and the plank formed by them partially forms a support part 8, and the support part 8 faces the card body One side of the groove 63 forms a first abutting surface 83, the side facing the matrix groove 61 forms a second abutting surface 81, and the side facing the insertion groove 62 forms a third abutting surface 82; the second abutting surface 81 A chamfered second inclined surface 84 is formed at the junction with the third abutting surface 82 . Half of the connecting piece 7 is first inserted into the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com