Triaxial rheological test process and method for hard and crisp rock

A triaxial rheology, hard and brittle technology, applied in the direction of strength characteristics, instruments, measuring devices, etc., can solve the problems of poor applicability of high-hardness rocks, no clear indication of grade number, and inability to guarantee the accuracy of results, etc., to achieve the reduction of axial The effect of increasing the output force level, avoiding deformation mutation, and reducing test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

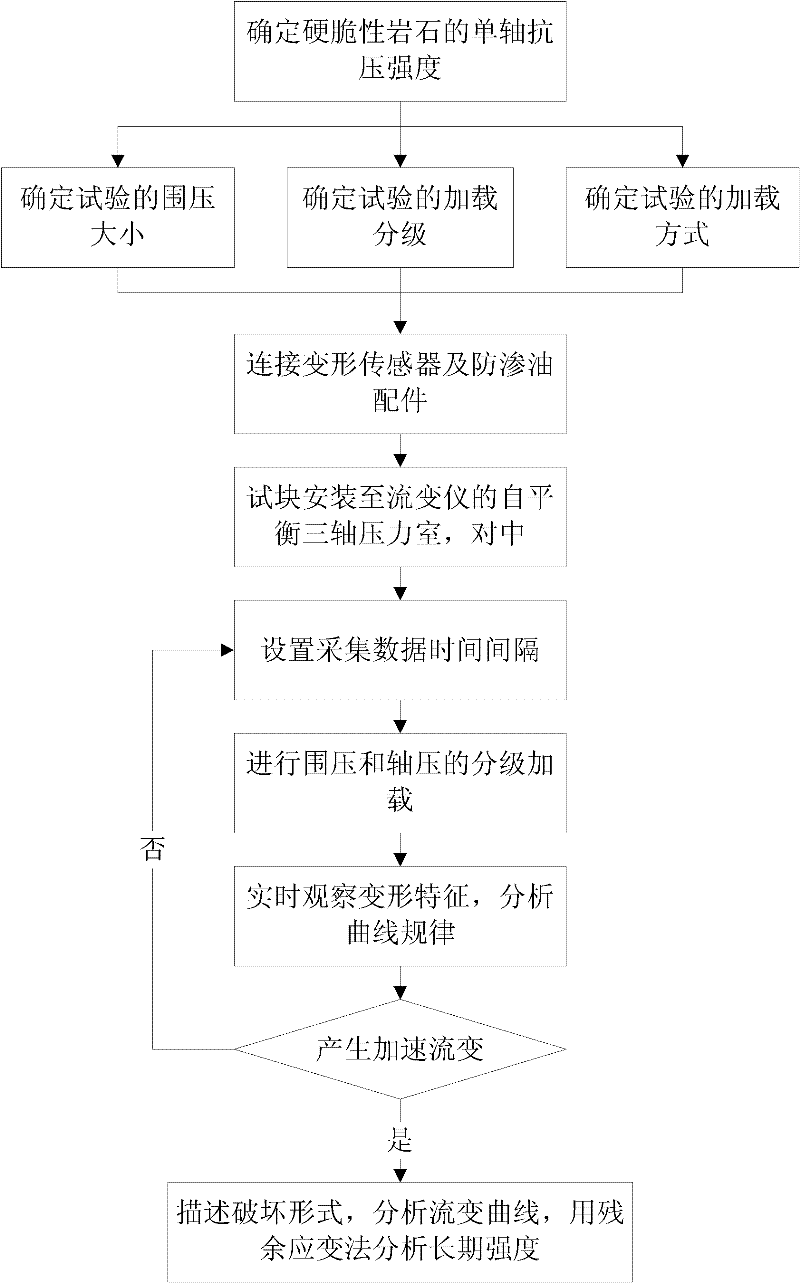

[0038] A triaxial rheological test technique and method for hard and brittle rocks, comprising the following steps:

[0039] 1) Determine the uniaxial compressive strength of hard and brittle rocks, and use the triaxial rheological method for loading.

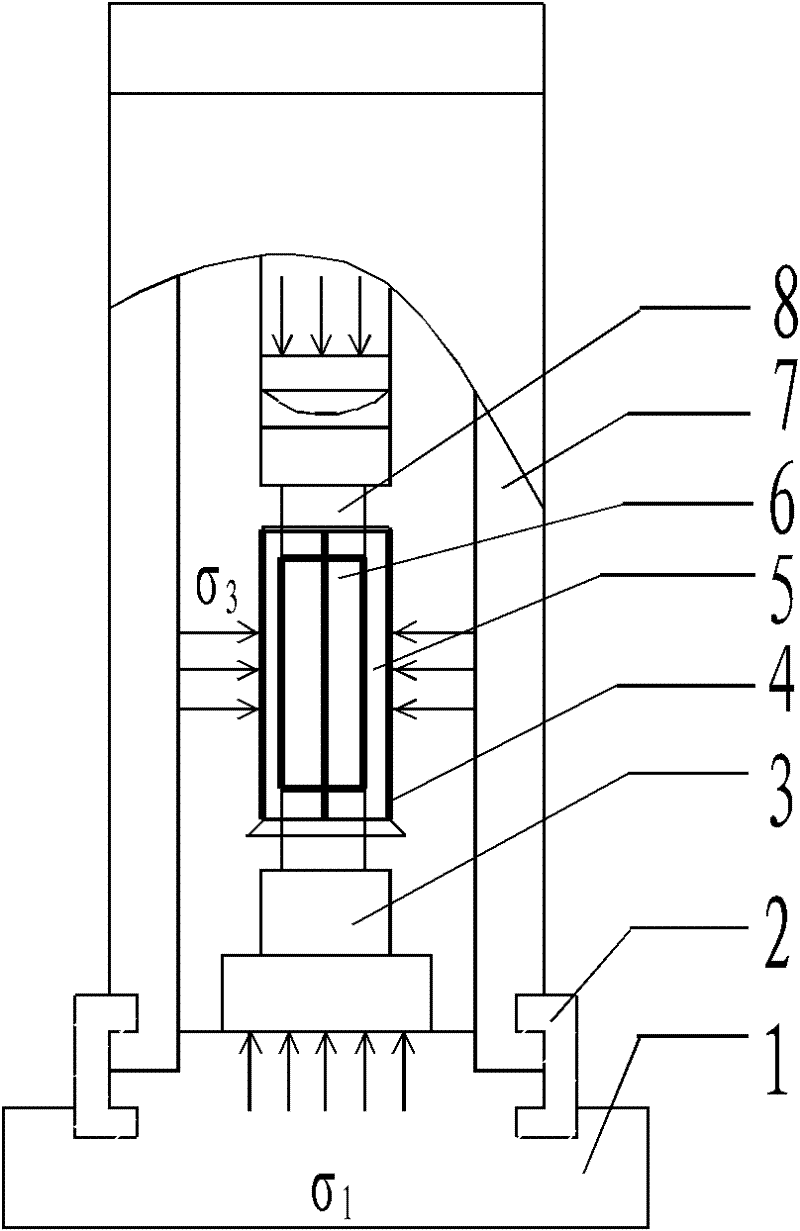

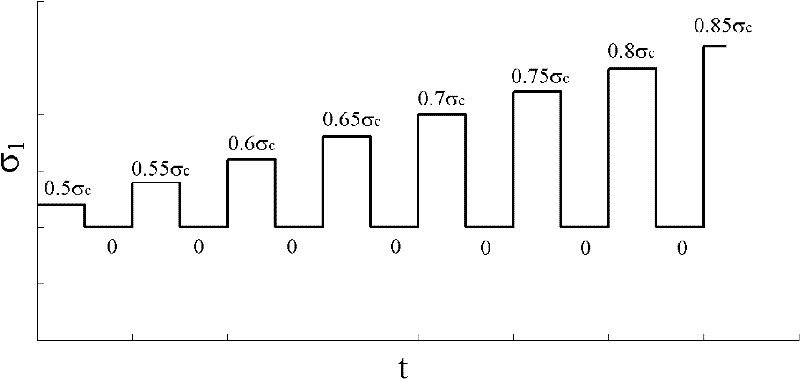

[0040] 2) Determine the confining pressure of the test, test loading classification and loading method. Confining pressure σ 3 The recommended value is σ cu is the uniaxial compressive strength of the rock. The test loading classification is recommended to be 6-8. According to the existing research results, the long-term strength of hard rock is assumed to be σ ∞ =(0.7-0.8)σ c , therefore, the axial pressure σ of the triaxial rheological test 1 Proposed to be 0.5σ c , 0.55σ c , 0.6σ c , 0.65σ c , 0.7σ c , 0.75σ c , 0.8σ c or 0.85σ c , σ c is the instantaneous failure strength of the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com