Clamping-pressure-formation-based proton exchange membrane fuel cell metal bipolar plate processing method

A metal bipolar plate, proton exchange membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as unfavorable mass production, low processing efficiency, complex process, etc., to achieve easy mass production, improve processing efficiency, and process technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

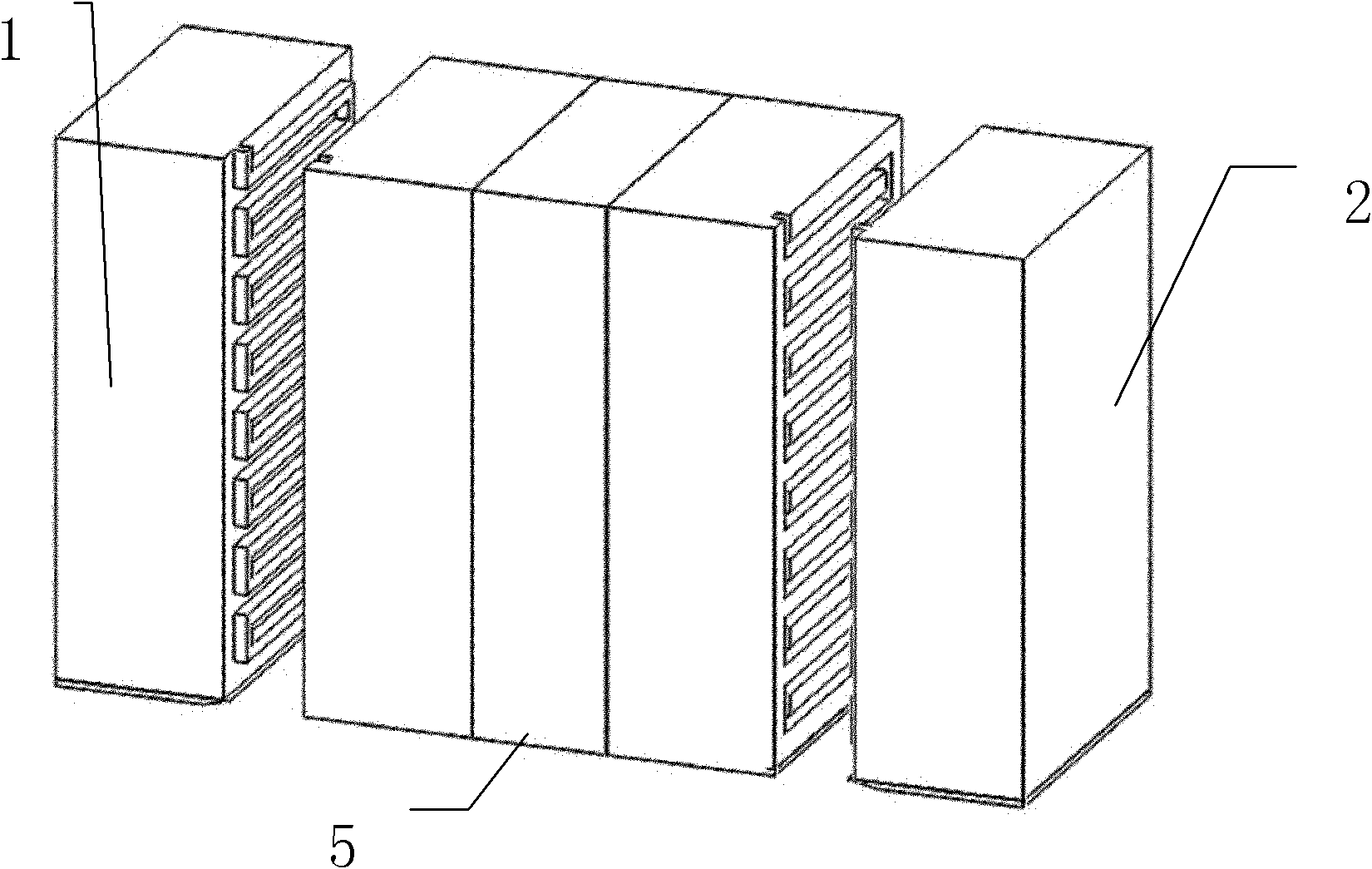

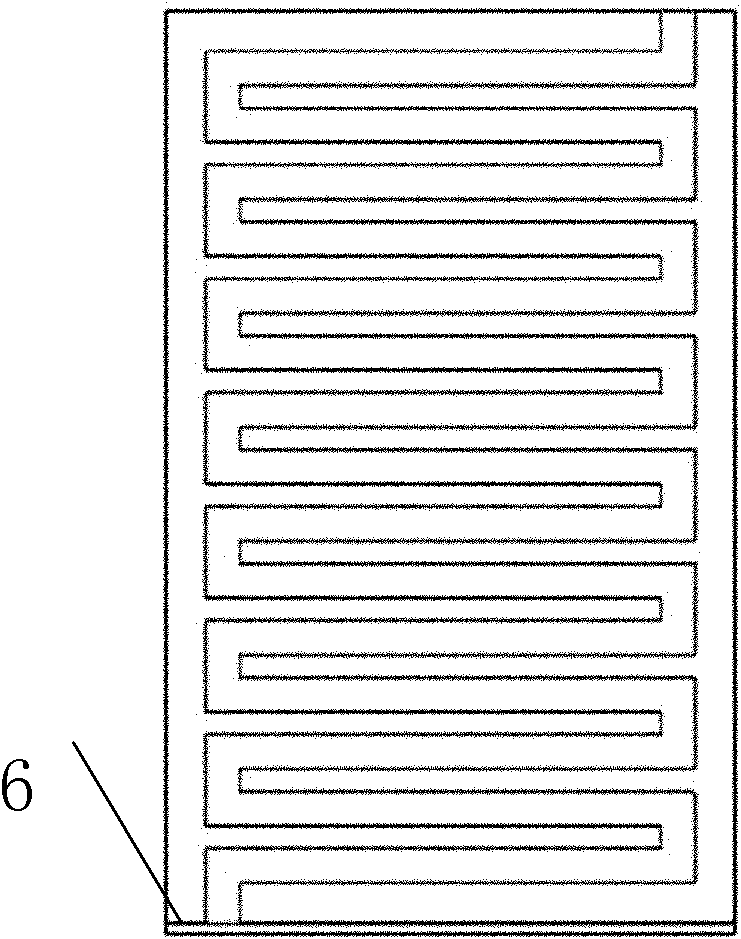

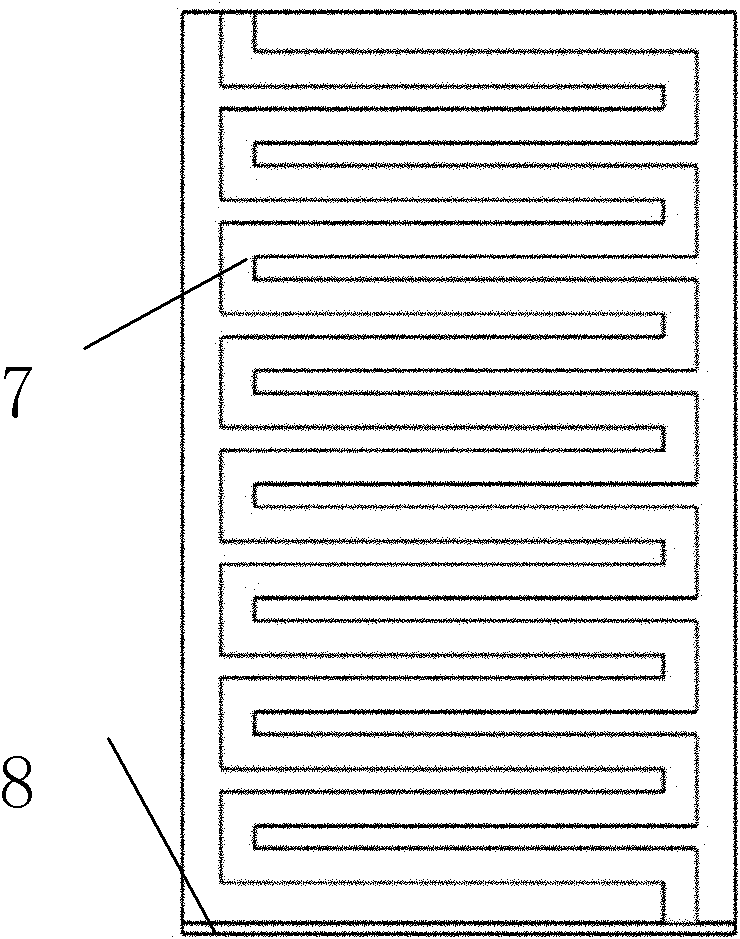

[0020] refer to Figure 1 ~ Figure 3 , a method for processing a metal bipolar plate for a proton exchange membrane fuel cell based on press forming, the processing method comprising the following steps:

[0021] (1) According to the design requirements of the proton exchange membrane fuel cell metal bipolar plate, the mold for clamping and forming is processed, and the mold includes a left and right convex steel mold and a middle composite mold, and the middle composite mold includes a left Concave steel mold, soft mold and right concave steel mold, described left convex steel mold is directly opposite to described left concave steel mold, described right convex steel mold is directly opposite to described right concave steel mold, and described left convex steel mold The gap between the left concave steel mold and the gap between the right convex steel mold and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com