Core breaker with dust suppression system

A crusher and rock core technology, applied in cutting machinery, slitting machinery, earth drilling and mining, etc., can solve problems such as equipment danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

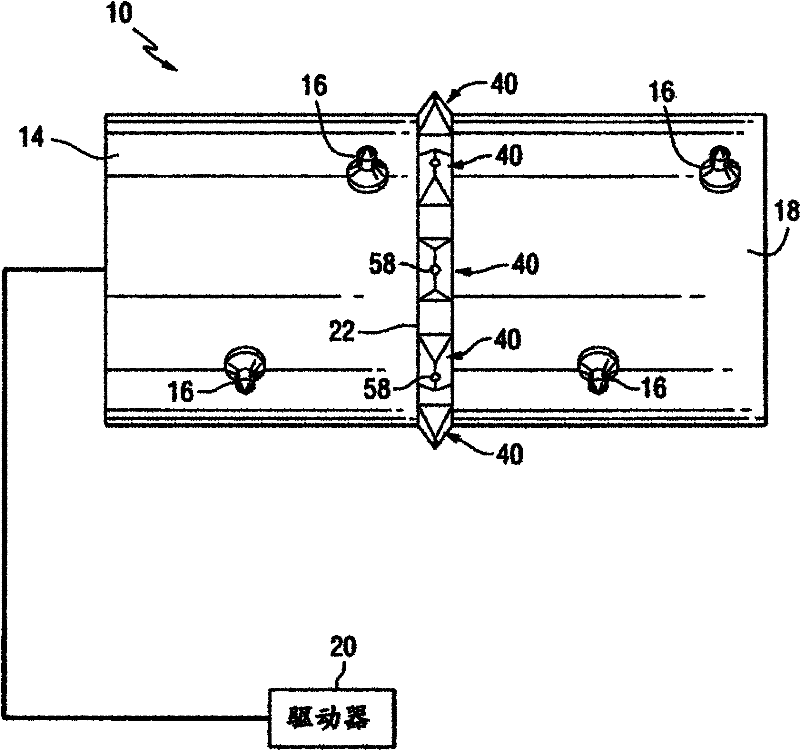

[0012] According to an aspect of the present invention, with reference to these drawings, figure 1 A portion of a continuous mining machine (ie, a formation cutting assembly), generally designated 10 , is shown. The continuous mining machine 10 includes a first rotatable cutting drum 14 exhibiting a plurality of cutting tools (or drill points) 16 arranged in, for example, a helical pattern. The continuous mining machine 10 further comprises a second rotatable cutting drum 18 which also exhibits a plurality of cutting tools (or drill tips) 16 arranged eg in a helical pattern. The first cutting drum 14 is spaced apart from the second cutting drum 18 but can still be considered adjacent thereto. The cutting drums 14 , 18 are operatively connected to an electric motor 20 which drives the rotatable cutting drums 14 , 18 . A core breaker 22 is positioned between the first cutting drum 14 and the second cutting drum 18 .

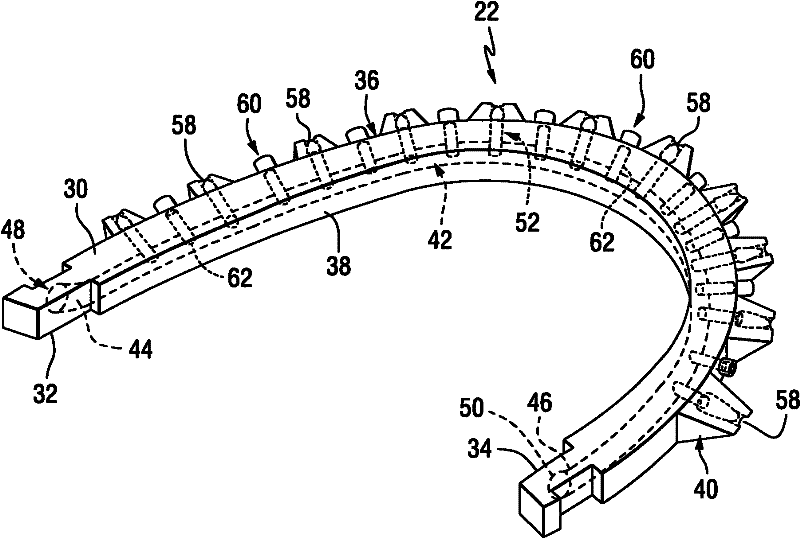

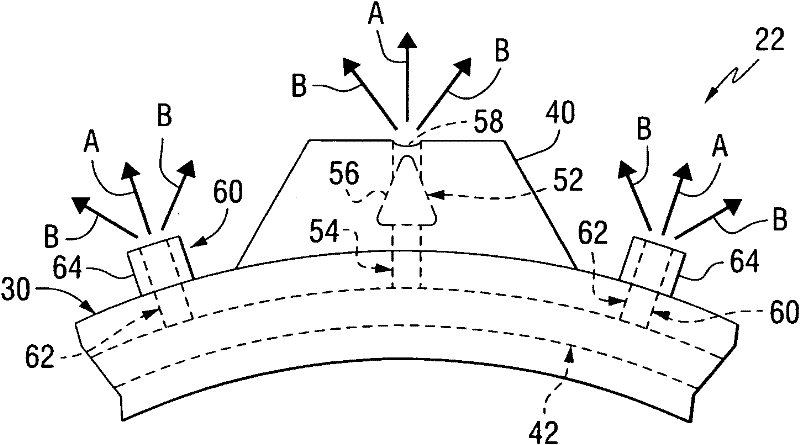

[0013] According to one aspect of the present invention, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com