Power transmission device of natural energy recovery system

A technology of power transmission device and natural energy, applied in transmission device, gear transmission device, transmission of mechanical power, etc., can solve problems such as inability to issue braking commands, inability to fully correspond to motors, and low reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

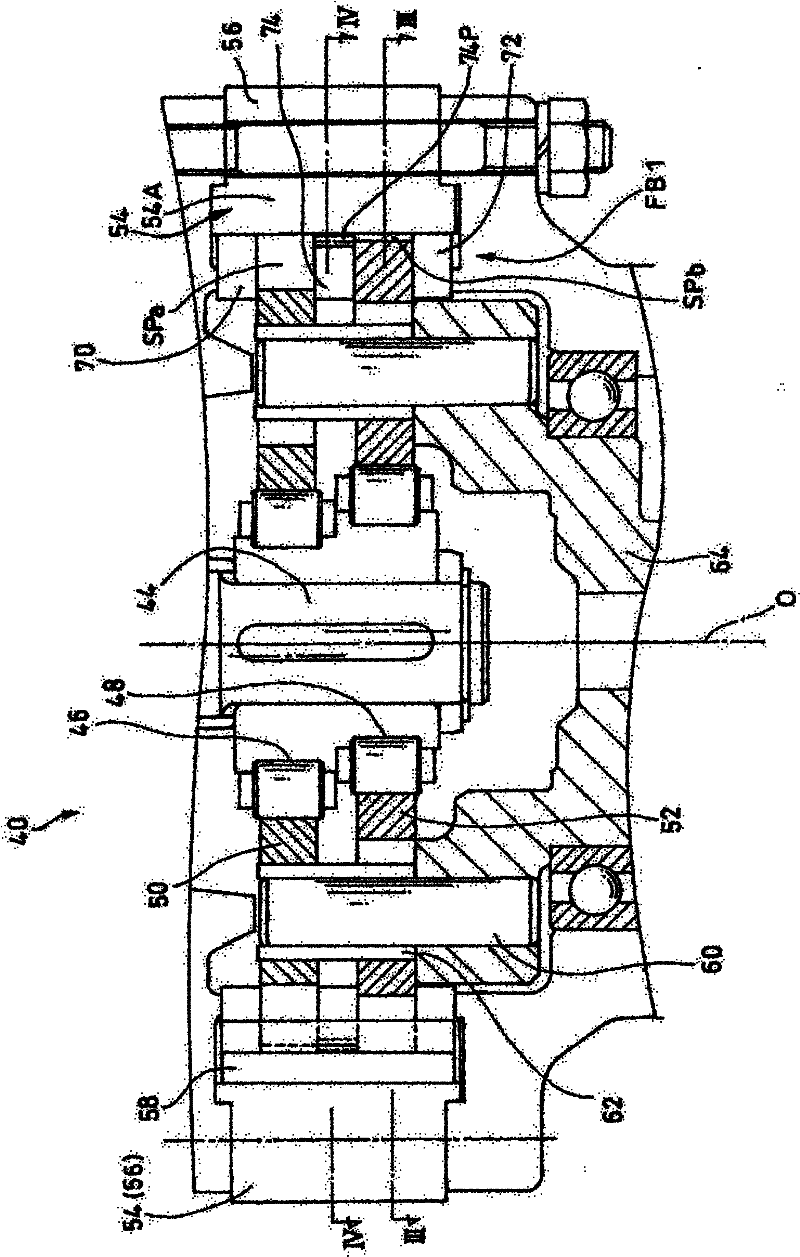

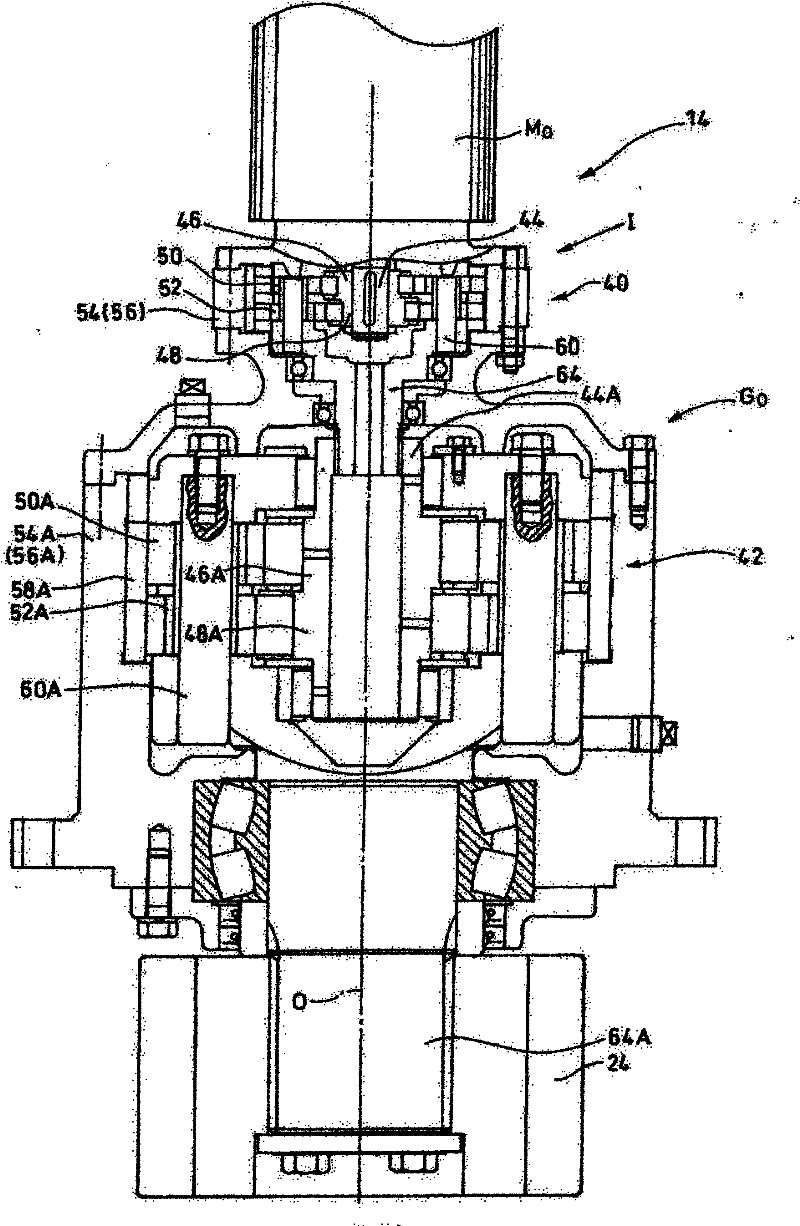

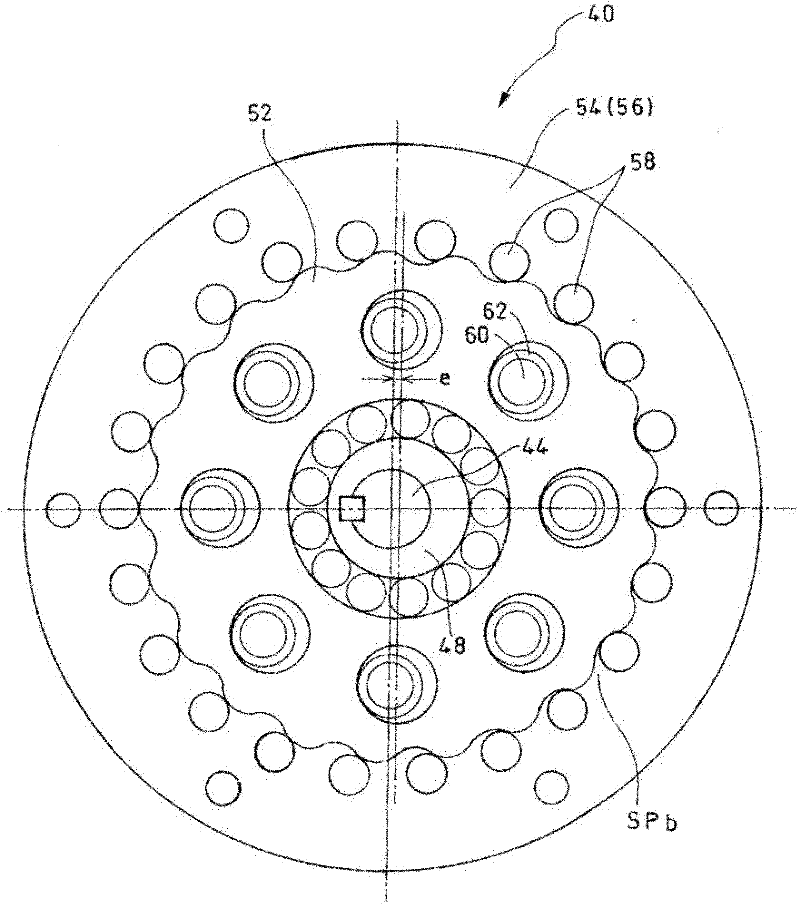

[0036] Hereinafter, an example of a case where a power transmission device of a natural energy recovery system according to an example of an embodiment of the present invention is applied to a drive device of a wind power generation system will be described.

[0037] Figure 17 18 is a schematic front view of the wind power generation system 10, and 18 is this side view.

[0038] This wind power generation system (natural energy recovery system) 10 includes a power generation unit 12 on the uppermost portion of a cylindrical support 11 . Figure 19It is a schematic perspective view showing the power generation unit 12 . A drive device (power transmission device) 14 for driving a yaw (power transmission device) and a drive device 16 for driving a pitch (pitch) are inserted into the power generation unit 12 . The driving devices 14 for yaw driving are used to control the rotation angle of the entire power generating unit 12 , and four are drawn in the illustrated example. The...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap