Composite stairs and manufacturing method thereof

A manufacturing method and technology for stair slabs, which are applied in the directions of stairs, manufacturing tools, treads and vertical slab units, etc., can solve the problems of poor impact resistance, poor wear resistance, and easy warping, and achieve safe and beautiful warping or Deformation, not easy to warp or deform, the effect of easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiments and with reference to the accompanying drawings.

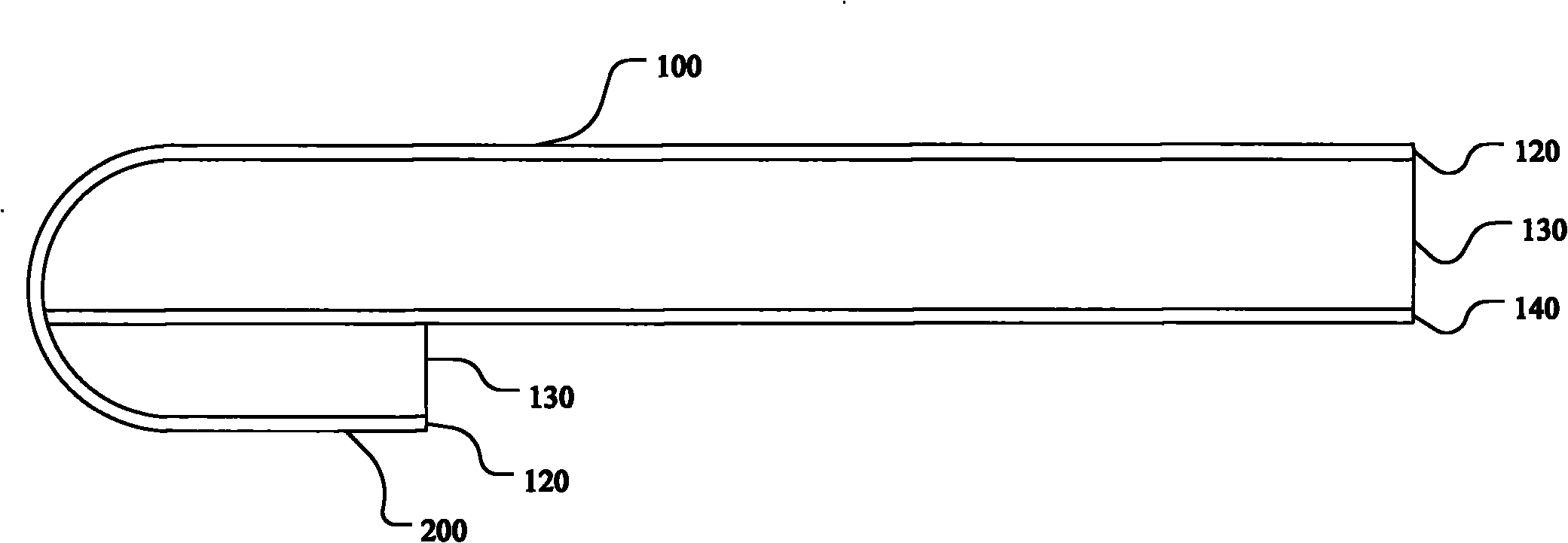

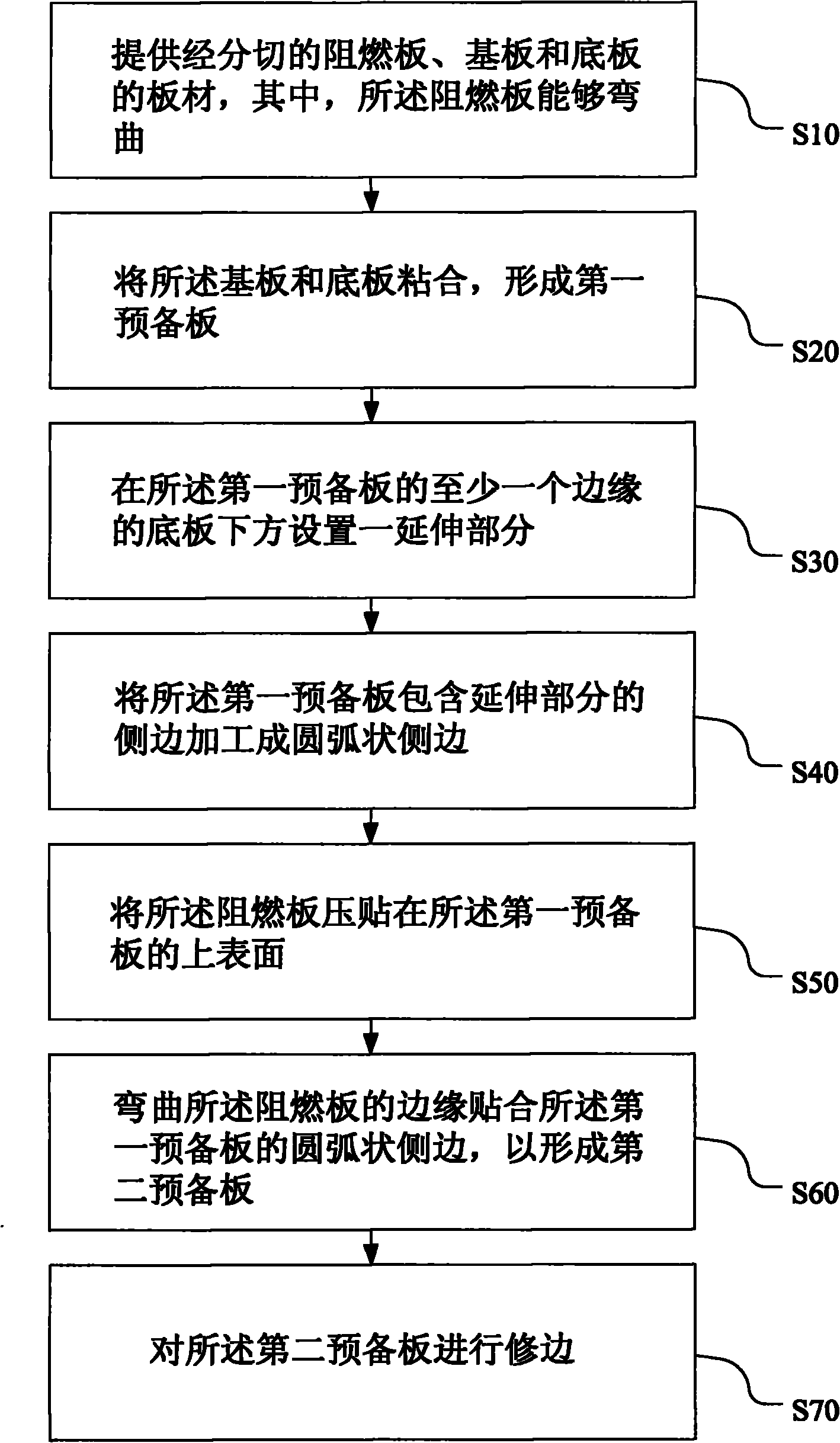

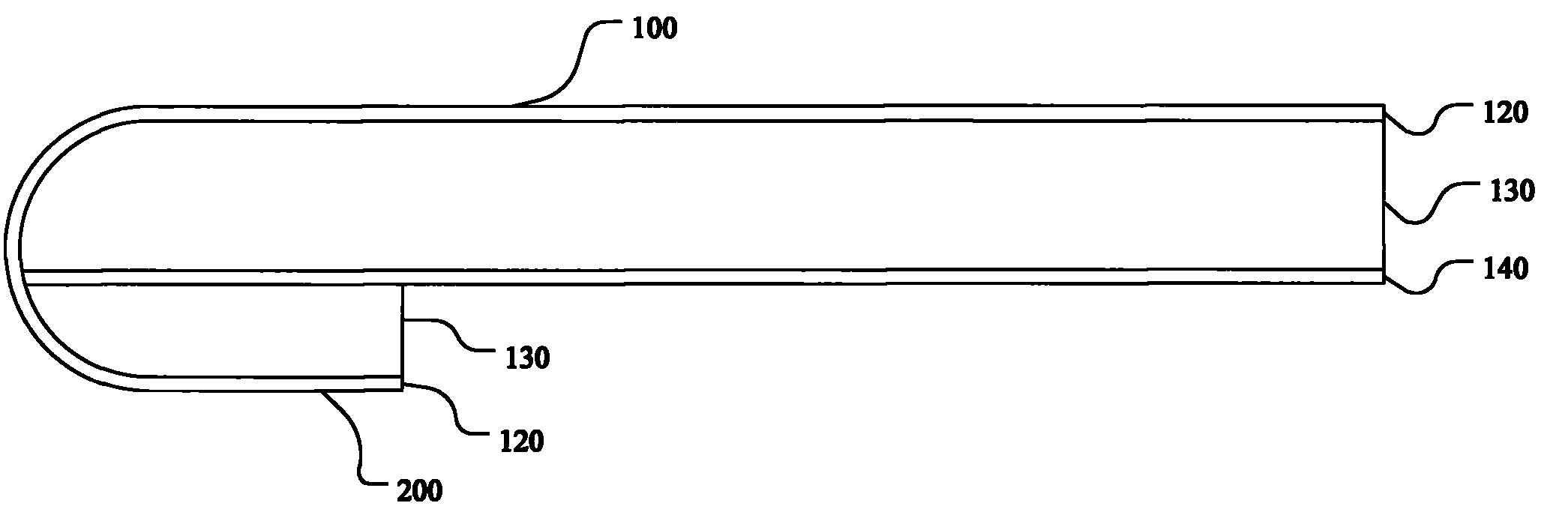

[0031] Such as figure 1 Shown is a specific embodiment of the composite stair board of the present invention. A composite stair slab, comprising at least a main body 100, the main body 100 sequentially includes a wear-resistant textured layer 120, a base layer 130 and a bottom layer 140 from top to bottom, wherein the wear-resistant textured layer 120 adopts a weight of 70-100 g / m 2 The bendable flame retardant plate, in this specific embodiment, the flame retardant plate weight is 80g / m 2 ; The thickness of the base layer 130 is 8-30 mm, and the base layer 130 adopts medium and high-density boards, and the density range of the density boards is 750-830 kg / m 3 , in this embodiment, the thickness of the base layer 130 is 10mm, and the density of the density board is 830kg / m 3 ; The bottom layer 140 is made of balanced paper.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com